Surface texturing with pulsed fiber lasers

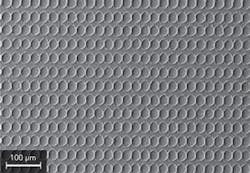

Laser surface texturing is a viable technology for surface engineering that can produce significant improvement of engineering components in aspects such as wear resistance, wetting characteristics (FIGURE 1), friction coefficients, load capacities, and part lubrication. Lasers provide a fast and accurate method for manufacturing textured surfaces, where the laser parameters and conditions yield excellent control over the size and shape of surface features.

Fiber laser technology is a relatively new laser source that offers users a compact, low-cost solution with no maintenance requirements, yielding a low cost-of-ownership solution.

Since the mid-1990s, MAN Diesel & Turbo (MDT), a global leader in manufacturing marine diesel engines, has used special discs to increase the friction between two counterparts. These special discs are mounted between the two engineering parts; a thermal sprayed coating containing hard carbides is applied to the discs’ surfaces, interlocking them with the counterparts when bolted together.

All MDT designs with high-friction coatings apply the friction coating to both mating surfaces of a disc/shim. The shape of the disc/shim is based on the design of the assembly. The two surfaces for high-friction coatings are always parallel.

A good example of where such parts are applied by MDT is in the use of friction discs when mounting a turning wheel to a crankshaft (FIGURE 2). The friction disc prevents any possible slip in the bolted connection.In current manufacturing practice, the coating consists of blended powder (Cr3C2 and Ni-Cr) applied by atmospheric plasma spraying. When producing thermal sprayed coatings, many parameters can influence the finished coating: gas pressures and flows during spraying, velocity of the combustion flame, powder, handling of the powder, preparation of the surface prior to spraying, equipment for movement of the spraying equipment over the surface, and maintenance state of the spraying equipment. Close control of the process is required to ensure the desired coating is achieved. Additionally, the quality of the powder can vary due to content variations of ingredients in the powder blend, size distribution, powder density, and even variations in the powder production systems themselves — all of these can influence the reproducibility of a coating.

Manufacturing consistency can therefore be problematic with the thermal sprayed coatings, lowering the friction coefficient and impacting product yield and quality. Other production issues related to the motion equipment of the spraying equipment at a subcontractor facility can result in an uneven distribution and layer thickness. The measured friction coefficients can be variable — with a significant spread even in the same spraying batch — but the highest friction coefficient tested is 0.62.

Due to these factors influencing the reproducibility of the thermal sprayed coating, MDT has been actively looking for an alternative manufacturing technology.

One evaluation was surface roughening by grit blasting using white aluminum-oxide. The tests turned were acceptable, resulting in the same or a higher friction coefficient than for the thermal sprayed coating. However, an unacceptable level of variability in the quality of the grit blasted surface was experienced, mostly related to the grit used. When the grit is recycled it degenerates, decreasing the average grit size and rounding off the grit edges; this results in a lower final roughness of the treated surface, thus changing the friction coefficient.

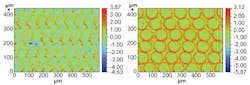

To improve reproducibility, MDT turned to laser surfacing using a beam scanning technique. For laser scanner processing, the key parameters are beam spot size, speed, and line spacing, which govern the individual spot separation or overlap. To achieve consistency, both the beam scanning speed and the line overlap must be aligned with the actual beam spot size achieved. The scanner-based system for surface patterning is extremely flexible with full software control enabling accurate positioning of the beam with approximately 5 µm repeatability, so that even cross-hatched angles between fill layers can be readily programmed.

An external focusing optic determines the beam spot size and the processing field. Using an F-theta lens of 100 mm focal length yields a field area of approximately 60 × 60 mm, while a 163 mm lens yields up to 120 × 120 mm. Larger areas can be easily accommodated by step-and-repeat processing.

Laser selection is another important consideration as the beam quality can have a significant impact. For example, pulsed fiber lasers from SPI are available with three different beam quality (M2) values. The beam quality not only affects the ultimate beam spot size, but also the energy distribution both of which affect the resulting surface texture.Parameters can be controlled and easily changed to optimize the surface characteristics. Friction coefficients of up to 0.79 can be achieved, a significant improvement over current plasma processing results.

The results illustrate the key process parameters that influence the frictional coefficients achieved: beam quality, beam spot size, pulse frequency, pulse energy, the pattern applied, and the number of passes.

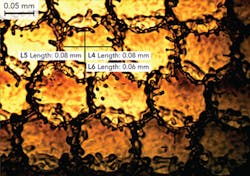

The use of laser texturing as a means to manufacture functional friction discs is a viable alternative to the current plasma spraying. An ongoing development and evaluation program continues to bring this process into production. Testing has moved from simple sample coupons to actual engineering components (FIGURE 6). Initial financial analysis suggests that laser processing is competitive with thermal sprays, with potentially lower capital equipment costs and no consumables.Laser technology offers the potential to produce surfaces with specific properties in a repeatable manner. A key advantage offered by lasers processing is that no consumables are needed, eliminating a significant source of variability. MDT is continuing its evaluation of this process with a view to future implementation in production. ✺

The SPI pulsed fiber laser with a master oscillator power amplifier (MOPA) architecture uses a directly modulated seed laser amplified using a proprietary fiber laser-based amplifier chain. This design allows the pulse parameters to be more effectively controlled than conventional Q-switched Nd:YAG-type sources, giving more scope for surface engineering. These sources can be operated from CW to 1 MHz and allow pulse length selection from 10-240 ns, optimized for peak power for a specific frequency. The generation of surface textures by lasers is primarily governed by the pulse characteristic and process parameters. The pulse characteristics are typically specified by the pulse energy (mJ), peak power (kW), the pulse duration (ns), and repetition rate (kHz).

About the Author

Jack Gabzdyl

Industry Manager – Electronics, TRUMPF Laser UK Ltd

Dr. Jack Gabzdyl is Industry Manager – Electronics at TRUMPF Laser UK Ltd (Southampton, England) and has more than 30 years of laser materials processing experience. He obtained his PhD in laser processing from Imperial College London in 1989. He has since had a number of technical and marketing positions at BOC Gases, Advanced Laser Solutions, and TWI before joining TRUMPF (formerly SPI Lasers) in 2007.

Erica Brorson Hansen

Erica Brorson Hansen is with MAN Diesel & Turbo in Copenhagen, Denmark.