Sergey Broude

Comparing direct-write vs. mask projection for medical device manufacturing

Laser micro-drilling describes the use of a laser to drill precise orifices in various materials. In the case of drilling polymer materials, especially polymer-based medical devices where hole precision, accuracy, and quality are critical attributes, the choice of machining technique is as important as the laser wavelength selection. This article illustrates the variety of micro hole-drilling techniques to demonstrate how the laser industry has advanced the depth of technology and know-how and applied these techniques to specific needs of industry. For example, in the medical device and diagnostics market, devices are becoming increasingly smaller and dimensions are approaching the 1 µm level, necessitating the need for micro laser drilling.

Laser drilling is a method of micro-machining that relies on controlled ablation, i.e., removal of material exposed to high-intensity laser irradiation. Usually, this term is applied to holes or openings with diameters between 1 µm and 1 mm. The exact mechanisms of material removal are defined by the specifics of the material, characteristics of the laser, and the configuration of the machining process.

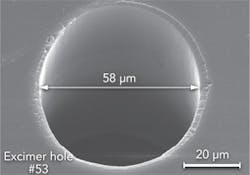

Basically, two major mechanisms are occurring: (a) photo-chemical, when laser photon energy directly breaks the bonds in the material, thus allowing the products to be expelled from the volume under illumination; and (b) photo-thermal, when absorption of laser energy by the material results in a fast temperature increase above the melting or evaporation point, so that material is removed by fast boiling or evaporation. The photo-chemical mechanism usually results in a ‘cleaner’ process because it is easier to prevent its gaseous products from re-depositing on the workpiece than to prevent droplets of molten material from re-depositing in the photo-thermal case. This is one of two major motivations to employ short-wavelength lasers, in particular ultraviolet (UV) and deep ultraviolet (DUV), for micro-machining of polymers (FIGURE 1) as their photons carry enough energy to break the bonds of the polymer chains. Another motivation is that with shorter wavelengths it is easier to achieve the higher spatial resolution required to fabricate small features, including holes of micron range (FIGURE 2).

Under most real-life situations, both of these mechanisms are operating simultaneously, and process developers are challenged to find an optimal combination of laser parameters (wavelength, pulse duration, and repetition rate), system optics (beam size, shape, and path on target, and energy delivery efficiency) and process conditions (gas environment, temperature, etc.) for micro-drilling of desired features into workpiece with its specific characteristics (dimensions and shape, material’s light absorption, and thermal properties, etc.).

Direct-write vs. mask projection

Micro-hole drilling is usually realized in one of two distinct configurations: direct-write and mask projection. In direct-write, a laser beam of a low-order mode (CO2, Nd:YAG and its harmonics, short-pulse solid-state lasers [pico- and femtosecond]), which is Gaussian in profile, is first conditioned (expanded and/or re-shaped) and then tightly focused on the workpiece. The relative motion of the beam with respect to the workpiece is controlled either by scanning the beam (e.g., galvo or acousto-optical scanners) or by translating the workpiece (linear, tilt, rotation), or by a combination of both. In this way, the desired pattern is produced in a sequential manner, point by point.

As applied to hole drilling, two variants of direct writing are mostly employed. In percussion drilling, a focused beam of a needed size dwells at desired location for a period of time necessary to drill a hole of required size and depth and then quickly moves to the next hole location. Trepanning involves moving a beam or the workpiece so that the beam follows a circular path of desired diameter. Percussion drilling is more applicable to smaller hole drilling, while trepanning can produce holes of any diameter. It must be noted that when the hole diameter is larger than a couple of beam diameters, an issue arises of disposal of the central slug left after the circumferential cut is made.

The Gaussian profile of these laser beams describes the fact that the intensity of the beam at its center is higher than at the periphery. This may result in over-exposure of the material in the center while the periphery does not receive adequate energy. Methods exist to convert Gaussian beams into flat-top beams of substantially uniform energy density, thus increasing the efficiency of laser energy usage.

There are also more advanced beam-modification approaches, such as transforming a Gaussian beam into an annular beam having an outer diameter corresponding to the desired hole diameter, and then using it to drill holes without need for circular scanning.

Direct-write hole drilling, while being versatile and flexible, suffers from its sequential nature. To benefit from higher laser powers becoming available under conditions when maximum power usage per hole is limited (e.g. by undesirable heat-spreading effects), the available laser power should be split into several beamlets which are then all used for parallel drilling in multiple locations simultaneously. For this, several techniques are available (and more are being developed): geometrical optics beam splitters, diffractive optics elements, acousto-optical devices, etc.

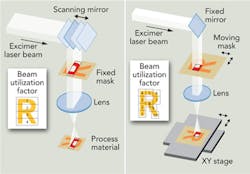

Lasers with higher-order modes (UV excimer, TEA-CO2) produce quasi-uniform beams of relatively large cross-sections, and are usually employed in a mask-projection method. Here, the laser beam is conditioned (expanded, reshaped, and/or made more uniform in energy density, i.e. homogenized) and then directed to a mask having the desired pattern, which in the case of hole drilling may be an array of multiple holes. A projection lens is used to deliver (and usually to reduce in size, and thus increase energy density) the entire pattern of light transmitted by the mask to the sample, thus enabling simultaneous drilling of all holes on the mask illuminated by the beam (FIGURE 3, left). Step-and-repeat or mask-scanning approaches can be used to access larger areas of the workpiece.

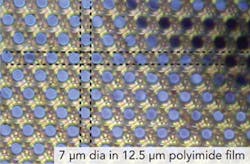

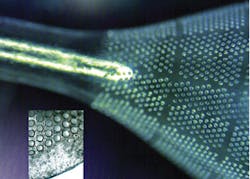

The mask-projection approach allows for use of projection lenses with high numerical apertures, which (for a price) can be well-corrected for aberrations, thus enabling creation of high-resolution images on the workpiece (FIGURE 4). With mask-projection, large numbers of highly-repeatable holes of a few microns in diameter can then be produced in parallel for each exposure. It is worth noting that, if a step-and-repeat approach with fixed mask is used to cover the entire area of the workpiece, care should be taken to ensure precise stitching of features produced at subsequent steps. This can be achieved by employing sophisticated motion stages and controls, and by ensuring the absence of distortions across the field of the projection lens.

When a pattern to be machined into a workpiece is not amenable to the step-and-repeat approach because of its non-repeatable nature, different masks must be used for different sections of the workpiece. Alternatively, a single mask as large as required for the entire pattern can be used in a coordinated opposing motion (COM) approach (FIGURE 3, right). In COM, the mask is moved with respect to a stationary laser beam in such a manner that all regions of the mask are sequentially illuminated by it, and thus projected on a synchronously moving workpiece so that the appropriate regions of it are exposed to the projected images. Because of the reduction in image size by the projection lens, the velocity of workpiece movement is reduced by the same factor as compared with the mask velocity, and its direction is reversed.

Controlling the hole profile

In both direct-write and mask-projection processes, the deeper the hole being drilled, the more pronounced the effects of this depth — restriction of incoming radiation by the edges of the hole, reflection of light by the hole walls, and attenuation of incoming radiation due to absorption in the ablation plasma contained in the hole. Advanced optical methods exist for tailoring the incoming beams so that edge effects are minimized or controlled, to produce holes with desired depth profiles.

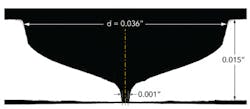

Another method of hole profile control is a hybrid of mask projection and trepanning that allows for the creation of funnel-like holes (FIGURE 5), where the mask projection defines the narrow diameter of the funnel while the trepanning motion controls its wider entrance.

In cases of non-planar workpieces, both direct-write and mask-projection are limited by the optics’ depth-of-focus — that is, the range along the beam over which the image or laser spot are still sharp enough. In such situations, the workpiece surface must be subdivided into flat-enough sections, each of which can be exposed sequentially; each of these sections is then presented perpendicularly to the oncoming beam. This can be accomplished by appropriately translating and/or rotating the workpiece about several axes. When the COM approach is used, mask motion may also include several translations and rotations occurring in synchronization with workpiece motions and laser firing. For example, a system for drilling multiple micro-holes in a bullet-shaped polymer filter (FIGURE 6) — essentially, a cylindrical body with conical and spherical tips — requires nine axes of controlled motion: six of the workpiece and three of the mask.

The selection of direct-write, mask-projection, or hybrid micro-laser drilling techniques depends on a myriad of factors, including the selection of the laser source, laser wavelength, material type, and specific part geometries and machining dimensions. Laser contract manufacturers have applied these drilling techniques to specific industries, such as medical devices and diagnostics, to meet the stringent design and commercial requirements, dictated by a market that is continuously shrinking geometries and complicating designs. ✺

Dr. Sergey Broude ([email protected]) is vice president of technology at Resonetics LLC (www.resonetics.com) in Nashua, New Hampshire.

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles