Cuvette cutting

A compact laser workstation enables volume production of disposable plastic cuvettes for a multifunction blood analyzer

Matthew Bye and David Clark

Avox Systems (Fair Oaks Ranch, TX) was founded in 1976 by Dr. A.P. (Pete) Shepherd, Greg Riedel, and colleagues from the University of Texas Health Science Center (San Antonio, TX). Shepherd explains, “In the late 1980s John Steinke and I developed an optical method to measure the four major hemoglobin species that didn’t require rupturing the red blood cells, unlike earlier techniques. By combining this method (that has since been patented) with a disposable cuvette (sample chamber), we were able to design smaller, faster instruments than the conventional test platforms. One of our products is used in cardiac catheterization labs where cardiologists sample blood in the right side of the heart to diagnose abnormal connections like atrial septal defects. Our other product is used primarily to assess the oxygen-carrying capacity of a patient’s blood in settings such as emergency rooms and critical care units.”

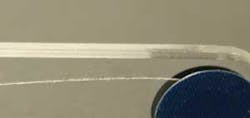

A critical piece of hardware in the Avox system is its patented sample cuvette. This is a small disposable container with a “fish-shaped” chamber (see Fig. 1) that is filled with the blood sample and then inserted into the instrument.

Several issues contributed to determining the cuvette shape, materials, and manufacturing method. Optically, the cuvette required reasonably large entry and exit windows with a very thin inner dimension (around 100 microns). The cuvette is disposable, because it would be too time consuming and problematic to clean and refill multi-use cuvettes. Thus, low-cost manufacturing is essential. However, during production, the optical surfaces of the final cuvettes must be protected from build-up of cutting debris.

Laser cutting

Before developing these disposable cuvettes, the Avox team had no previous experience with manufacturing. After investigating several possible material combinations, the company settled on an acrylic/mylar/acrylic combination.

Avox purchases Mylar sheeting with a thickness of just over 100 microns. The Mylar is coated on both sides with a contact adhesive. Each sheet is die-cut by the supplier, removing fish-shaped pieces of material, essentially leaving a pattern of gaskets that will form the middle layer of the cuvettes. Typical sheet dimensions are 188 mm x 635 mm, which works out at 90 cuvettes per sheet.

Avox production personnel then manually sandwich this die-cut Mylar sheet between two sheets of thin, clear acrylic with a nominal thickness of 1.4 mm. The outer surface of each acrylic sheet also carries a protective layer of lightly adhesive paper, which is removed after all manufacturing steps have been completed. The final overall thickness of this multi-layer laminated sheet is around 3.2 mm.

After lamination, the challenge is to singulate the cuvettes while allowing several post-cutting processes. These processes include installing a black cap at the square end of each cuvette. This allows blood to be introduced using a standard syringe. In addition, a small circular patch of GORE-TEX is attached over a hole in the acrylic toward the rounded end of the cuvette. This allows air to escape while confining the blood, enabling the thin cuvette to be filled without a back-pressure problem. To support easy implementation of these additional processes, the company does not use the laser process to completely separate the individual cuvettes-they are cut out leaving a small, perforated spur for each cuvette. This allows them to be handled in sheets while enabling simple manual snapping at a later stage.

At first, Avox tried different mechanical methods for the cutting/singulation process, including sawing and die cutting. Saw cutting proved to be too time consuming and inconsistent. Also, both sawing and particularly die-cutting would often cause the various layers of the acrylic/Mylar sandwich to slip and shear because of the soft adhesive, ruining the product.

The company then turned to laser cutting, initially out-sourcing this work to a U.S. job shop. As volumes started to rise, the company made the strategic decision to bring this process in-house and acquired its own CO2 laser workstation in 1996.

Volume manufacturing-speeding up production

As its manufacturing experience has grown and its product volumes have increased, Avox has twice upgraded its laser cutting process, acquiring its third laser system in 2004. This is a Beam Dynamics LMC 5000 system incorporating a slab discharge CO2 laser (Coherent Diamond series) rated at 250 watts and operating at a pulse rate of 10 kHz (see Fig. 2). Shepherd explains that, “We’ve experienced tremendous sales growth since we purchased our first laser cutting system. We sold about one million cuvettes in 2004 alone, and this growth has caused us to re-assess how we manufacture these products, with a particular focus on minimizing cost and labor, and maximizing our throughput and overall yield.”

Several aspects of this cutting system combine to deliver these benefits for Avox. One of the most important features for this application is the automated machine vision, integrated into this workstation. In conjunction with the large 1.22 m x 1.22 m cutting bed, this enables high-speed cutting of large numbers of cuvettes.

The acrylic/Mylar sheets are manually laminated and then placed on the cutting bed. The laser cutting must be registered to the inner Mylar layer because this die cut sheet defines the dimensions and location of the cuvettes. Shepherd notes that, “With our previous workstations we wasted far too much time aligning the laser cutter with the Mylar.” With the Beam Dynamics system, the laminator places two black dots on the top surface that are aligned with small registration holes cut through the Mylar layer. The machine vision system is set up for low-contrast shape imaging. Once it has found the black dots, it is able to process the entire sheet, move to the next sheet, and align itself on the black dots on it. Shepherd explains that, “The machine can tolerate misalignment (misplacement) of the black dots up to 12 mm. This allows the operator to quickly place up to six of our laminated sheets on the cutting bed and leave the machine unattended. At 90 cuvettes/sheet, that’s 540 cuvettes without any operator adjustment.”

The overall laser power and fine power control are the other important factors enabling high throughput rates at Avox. Because the laser power is 250 watts and the system uses high-speed flying optics, the laminated sheets can be cut at 100 mm/second. As is typical in plastic cutting applications, the laser is operated in a fast-pulsed mode with square-shaped pulses, in order to maximize the piercing and cutting power while minimizing peripheral thermal damage. But in order to obtain smooth-edged cuts with a pulsed beam, the laser power must be dynamically adjusted based on the geometry of the cut (see Fig. 3). Extensive experience has allowed Beam Dynamics to build “look-ahead” contouring into the machine, ensuring that all aspects of the cut part retain high-quality edges even on square corners and full circles. The end result is that the system can cut 540 cuvettes in only 20 minutes.

Conclusion

Precision workstations that incorporate machine vision and sealed CO2 lasers of up to 500 W have revolutionized cutting applications for non-metals. These economical products bring the advantages of laser cutting to smaller companies. At the same time, their output power supports cutting rates that are scalable to high-volume production. But perhaps most important, the simplicity and reliability of these laser workstations have empowered companies whose core specialty lies far from laser machining to enjoy the speed, flexibility, and consistent product quality that only laser processing can deliver.

Matthew Bye is with Beam Dynamics and David Clark is with Coherent Inc. Visit www.beamdynamics.com or www.coherent.com.