Despite the fact that they present a relatively new technology, diode lasers are established in a number of automotive applications in three-shift production and have already proven their effectiveness

Nearly all of the latest generation of German automobiles use one or more laser brazed seams to connect sheet metal in the car’s body. Brazing’s main advantages compared to welding are the smooth surfaces that are produced and the ability to avoid melting the zinc coating, which avoids corrosion or further treatment that would be necessary otherwise. Thanks to these advantages, laser brazing is employed for visible joints in areas such as tailgates, roof joints, and C columns.

In addition to demanding a high degree of mechanical stability, these visible seams must also have minimal heat affected zones and meet demanding optical requirements.

These high demands can only be met by laser technology. The use of Nd:YAG lasers for this application has already been established. Recently, however, diode lasers are being increasingly employed.

Typical process demands on the laser beam source for brazing are: laser power from 2 to 4 kW and spot size of from 1.5 to 3 mm at a working distance of about 150 to 250 mm. Both the above named solid-state and diode laser types equally fulfill these demands.

Bus communication interfaces such as Profibus DP or Interbus-S, 24-hour teleservice, beamsplitters/switches, and other optical components that are used for Nd:YAG lasers are also available for both types of lasers.

But what is it that distinguishes diode lasers from Nd:YAG lasers? Diode lasers present a clear advantage in areas of large-scale production because of their higher availability and reliability in production and because they are almost maintenance-free. The new generation of diode lasers achieves a lifetime of more than 20,000 laser hours, which is equivalent to about three to four years in a three-shift production environment. Lamp-pumped Nd:YAG lasers, on the other hand, need lamp replacement every 1000 hours, meaning a total of 20 maintenance actions in the same timeframe, with corresponding production downtime and costs.

If a flashlamp from an Nd:YAG laser fails, production needs to be stopped for roughly 20-30 minutes. As opposed to this, the use of an intelligent diode stack management allows for continued production with diode lasers, even if a stack unexpectedly fails. In this case, the integrated electronics system recognizes the faulty stack, turns it off, and recalculates new operating parameters. Then, the diode laser is ready for production again within two to five minutes. As a result, the replacement of faulty components can be planned within a long-term maintenance schedule.

The space they require is playing an increasingly important role. A diode laser takes up only one-fifth of the space required by an Nd:YAG laser with the same output power. Furthermore, because they are so compact, diode lasers can even be put on wheels and rearranged at short notice.

In addition to these advantages, the following process-oriented improvements have been achieved in using diode lasers. Experience has shown that in direct comparison of brazing a car’s tailgate, the diode laser produces better and smoother brazing seams than an Nd:YAG laser. It has been shown that diode lasers, thanks to their better spacial and time-stability in combination with their homogeneous beam profile with an approximate “top-hat” intensity distribution, bring about a particularly calm melt pool and thus result in a very stable brazing process. The final result of this is the smoother surface that is observed.

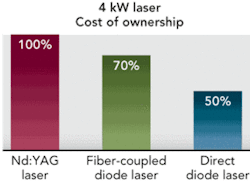

In a direct economic comparison (see Figure 3) between diode and Nd:YAG laser the classic hourly machine rate is not sufficient although it already results in excellent figures for the diode laser because of the overall efficiency being by far higher. In addition, maintenance costs and costs of replacement parts need to be taken into consideration, as do the costs of space requirements and energy. On top of that, the costs and production losses due to interruption of production and the costs of wasted parts should be considered as well. By taking into account also all these additional factors, diode lasers achieve a significant cost-advantage of more than 30% compared to lamp-pumped Nd:YAG lasers. In a comparison between another type of diode laser, the direct diode laser and the conventional laser, the cost-advantage goes up to 50%.

In many cases new investment in diode laser technology is more efficient than using Nd:YAG lasers even when Nd:YAG lasers are already in use. This basically results from substantially lower energy costs, costs of lamp replacement and interruption of production associated with Nd:YAG lasers.

Not only are the economic and process-oriented advantages valid for brazing in the automotive industry, they are now established in a multitude of other applications. For many years they have been used successfully in laser plastic welding and welding of thin metal sheets and in hardening and coating/cladding applications.

Dr.-Ing. Christoph Ullmanis managing director and Dr.-Ing. Andre Eltze ([email protected]) is in technical sales at Laserline GmbH, Munich, Germany. Visit www.laserline.de.