Laser beam welding in rail car manufacturing

Technology improves traceability in growing public transportation market

MARIANA FORREST and HOLGER ALDER

The benefits of laser processing in manufacturing of automotive bodies have been widely demonstrated over past decades—and recently, laser welding has received increased interest in rail car manufacturing. A number of welded assembly applications are already in production in Europe and Japan, and some are emerging in the US. However, these new rail car manufacturing applications involve complex and critical operations in which the acquisition and management of large amounts of process data is mandatory. Photon AG (Berlin, Germany) is a pioneer in this type of application in Europe, so this article illustrates how it is necessary to use digital process data management, from planning through production and monitoring, to achieve the highest efficiency possible and control all safety aspects.

Rail car market

The rail car industry is an interesting new market for laser welding applications because of the growing need for public transportation worldwide, thus increasing the amount of miles of welds to be produced. Examples of current production parts/benefits obtained using laser welding include:

Services and products

Along with supplying welded parts and assemblies, Photon also serves customers with applications know-how and process support worldwide. One important example is the FokusMonitor, a versatile system for process integration, monitoring, and diagnostics. Initially developed for Photon's own internal needs for developing and optimizing complex processes and monitoring production quality performance, the system integrates the company's internal experiences and expertise and, as a result, has become a Photon Laser Engineering (PLE) product. Currently, FokusMonitor systems are in use in over 180 installations worldwide in a variety of applications. These involve welding and dispensing processes that include laser welding, brazing, cutting, and cladding along 3D paths and trajectories, as well as in non-laser processes such as adhesive bonding and arc welding.

Process data along the manufacturing chain

Laser welding of complex safety-related assemblies in rail car manufacturing requires use of corresponding computer-aided design (CAD) and process data during the complete manufacturing process chain. Process data management is extremely important because all product models are available first as CAD data and have to be transformed into reality, including mastering all the tolerances from CAD (in 1/1000th of a millimeter) to a metal part with a 16m length. Furthermore, after the part is produced, analysis or at least storage of a large amount of production monitoring and quality data must be managed to support continuous optimization processes and meet, in case of critical assemblies, the traceability requirements.

In contrast to automotive and medical device industries, which produce smaller parts in much larger volumes, the rail car industry deals with laser welding of extra-large parts in very small volumes while having to meet at least the same safety requirements and provide very high process flexibility to handle:

- Various types (end cars, middle wagons, special modules, etc.);

- Various parts (side panels, doors, roofs, and long beams, among others);

- Various welding processes and geometries to be executed in several steps; and

- Safety documentation of actual-weld process parameters.

FIGURE 2 shows an example of a laser-welded side wall with approx. 400 weld seams.

Because the rail car industry is dominated by small, custom-fit volumes, almost every rail car can have its own design. Also, the industry is conservative because of the high safety regulations and liabilities for 30 years or more, and these conditions naturally lead to "never touch a running system" and "copy-and-paste" tendencies. A widely used approach is to create a new car by "mixing" existing models already proven for quality, which in turn leads to a slow innovation process. While there is high potential for optimization, the tough challenge that remains is that the laser technology used for high volumes and short product cycles by the automotive market has to be adapted to manage the new conditions of the rail market.

To achieve the speed and quality benefits of laser welding a component, all the flexible information has to be fed into a fixed, yet flexible and fully automated robot program before the first part is ever produced. As the best possible and efficient approach, all robot movements are simulated fully in 3D with real part, robot, and station geometry (FIGURE 3). The simulation has the additional intention to influence the design for manufacturing optimization.

Offline simulations cover planning of the complete assembly and welding sequence. For example, not only of the robot movement, but also of which part, at what time, in which program sequence, as well as of robot accessibility.

Analysis results are transmitted back to the part designer, who can now justify changes in the welding sequence and replace it with a new, more time- and/or cost-efficient sequence. The result of this complete, virtual process is a robot program that meets specific manufacturing process requirements:

- Automatic run;

- Modular programming;

- Safety first;

- Discreet user level with personalized access;

- Process parameter monitoring (e.g., FokusMonitor);

- Single-weld repair strategy on demand by a quality engineer; and

- Data management and documentation of all necessary and relevant information.

Traceability

The benefits of laser technology were introduced recently in the new European rail car designs, as evidenced by the European "ICx project"—the largest rail car project in Europe at present (160 trains for approximately €4 billion from 2017 to 2023).

Photon is supplying side wall segments (FIGURE 4) for the project, which involves approximately 30 different part types for which more than 2400 seam, start, and track programs have been generated. Manufacturing is running in two stations in two different plants using the same programs and weld processes. A 12-wagon train needs approximately 170 side panel segments with a safety-documented welding length of approximately 8000m.

Once the process design and planning is completed in the virtual world, the next major task is to use the virtual domain data in the real world.

To weld parts up to 20m long, real-world conditions have to be set accordingly. The systems used by Photon Laser Manufacturing (PLM) for rail car manufacturing include laser cabins up to 25 × 9 × 7m. Each cabin is loaded through roll-up doors with automated fixtures running on rails and is connected to solid state lasers up to 6kW. FIGURE 5a illustrates a laser welding station installed in the PLM plant, where a Trumpf TruDisk 4002 laser is used.

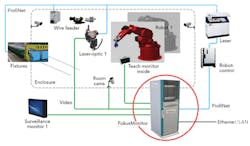

In addition to process safety and robustness, the most important aspect for achieving production reliability is the centralized station interface via the FokusMonitor (FIGURE 5b), including video surveillance, program selection, process control, program and data storage, company network and ERP connection, and—of particular relevance—process data monitoring.

The FokusMonitor is interconnected to the rest of the system and acts as the brain of the data management scheme (FIGURE 6). In addition to HMI and PLC functions, it performs many other functions, such as process monitoring, data acquisition, write-protected data storage, accessibility control, surveillance, productivity analysis, and working instructions, among others.

After setting up parts and fixtures beneath the robot (loaded with the prepared program), the program has to be calibrated to compensate tolerances and deviations coming from, for example, differences between the real machine and the simulation model, positioning of fixtures, placement of part on a fixture, part manufacturing, equipment misalignments, dynamical behavior during movement, and switching of time-dependent signals.

Even when using the best station and data concept design and implementation, overcoming the tolerances between theory and real parts remains the key aspect. Reproducing calibrated welding parameters with spot sizes between 0.5 and 1.5mm requires reaching ±0.1 mm focus-spot-to-joint positioning tolerance over 15m-long seams.

To achieve this, we combined available sensor technologies and developed the missing links. One such internal development is an offline calibration process using a vision sensor system based on the triangulation principle capable of semi-automatically correcting the planned-to-actual deviation.

FIGURE 7a shows a case of misalignment between part to programmed position, where the step in the line represents the joint position and the crosshair of the focal point position. In contrast to other available seam tracking systems, this proprietary system is working directly in the TCP (not running ahead), which also allows geometries with very small radii to be tracked and taught.

After calibration, the part is produced and the process is run and documented in the FokusMonitor. FIGURE 7b illustrates a screenshot of a sample production weld setup with lots of data visualized. All values shown (and even more not visualized) are filed together in one write-protected data file that is stored for manufacturing proof and traceability of every single weld in all single parts produced in that station.

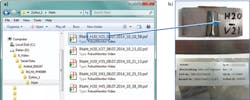

The directory tree screen (FIGURE 8, left) illustrates the data storage scheme, which uses folders and data files named according to part data and seam names, in which process files are stored based on product number, counter, welding sequence, seam number, and the date and time that the part was produced and the file was stored. Also, physical evidence of the weld process in the form of, for example, run-in and run-out tabs cut out of weld seams from the real parts is stored with the same structure and names (FIGURE 8, right). This combined storage of process records and physical evidence guarantees a 1-to-1 documentation chain for traceability of critical assemblies.

Mastering these challenges has resulted in high-quality laser-welded assemblies consistently supplied to customers for the last two years. FIGURE 9 illustrates a side wall segment exhibited at 2014 InnoTrans.

Conclusions

Manufacturing complex and safety-related weld assemblies with a high number of welds and a high variety of part models needs detailed planning that integrates all departments along the manufacturing chain, such as design, methods, programming, welding, quality, and production. A CAD model of a complete weld cabin, including equipment and an a priori simulation of all weld sequences, are indispensable for planning and programming. And finally, enhanced sensor and control technology is an essential addition to standard machine control to enable the transfer from theory to reality; process data monitoring is vital to control and optimize the production line; and process data storage is mandatory for traceability down to single weld parameters.

Dr. MARIANA FORREST([email protected]) is president of Lasap, Inc., Troy, MI, www.las-ap.com, and HOLGER ALDER is managing director of Photon Laser Engineering and CTO of Photon AG, Berlin, Germany, www.photonag.com.

Photon AG (Berlin, Germany), founded in 1998 as a spin-off from a joint venture between VW and Daimler, played an important role in the initial development of laser welding and brazing applications in automotive body-in-white manufacturing (i.e., roofs, deck lids, and doors). Currently, the company operates three subsidiaries in Germany, with international business throughout Europe, North America, and the Near East. Photon Laser Engineering (PLE) and Photon Laser Manufacturing (PLM) mainly serve the rail car industry—PLE develops the processes and necessary tools for the applications and PLM produces and delivers finished welded assemblies. Photon specializes in thin sheet-metal welded assemblies, with emphasis on the high surface flatness requirements used in high-speed trains, as well as in regional and commuter trains and locomotives. The company is certified per ISO 9001 for producing welded railway safety assemblies according to DIN EN 15085-2 Quality level CL1 (European Governmental Railway Certificate).