Cost-efficient laser arrays with built-in beam shaping

GÜNTHER DERRA

Now that diode lasers have finally conquered cutting, the holy grail of material processing, a new crop of diode lasers is joining the world of industrial lasers. Vertical-cavity surface-emitting lasers (VCSELs) now reach power levels that make them perfect sources for several lower-brightness industrial applications. As small, easily configurable, cost-effective heat sources, they are attractive enough to compete with traditional processes in plastic welding and in situ laser-assisted consolidation of thermoplastic composites with automated tape laying, where VCSELs' advantages come into play.

VCSELs are a newcomer to the industrial market, but are mass-produced for low-power applications. With an output power of 1–10mW for the individual diodes, they are mostly used in datacom, but also in sensors, gesture recognition, and many other low-power applications, with a growing market of about $500 million in 2014.

VCSEL, pronounced 'vixel,' describes the architecture and also the difference to current high-power diode lasers, which are edge-emitting lasers. In edge-emitting lasers, the laser cavities are stripes, buried in the semiconductor, parallel to the surface of the wafer. The emitters become lasers when the wafers are cleaved, with the two cleaved edges serving as mirrors. Their emission is in a highly asymmetric beam, and is subsequently combined to higher-power beams by various optical schemes [1].

VCSELs, by contrast, have their cavity perpendicular to the surface of the wafer. The largest VCSELs are about 20µm in diameter, and are emitting 10mW in a perfectly round beam. In a high-power chip from Philips Photonics, 2200 of these VCSEL micro-lasers are arranged on a 1.9 × 2.0mm chip, emitting more than 7W with a perfectly homogeneous beam profile. Since no cleaving is required, VCSELs can be tested on the wafer level, and standard semiconductor processes and equipment can be used for packaging, with costs similar to LED packaging. Higher power levels are achieved by arranging these chips in larger building blocks that can be combined to high-power modules in the kilowatt range [2, 3].

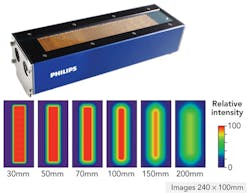

FIGURE 1 shows a laser module, emitting 9.6kW output power from a 40 × 208mm surface. The light coming out of the VCSEL module does not require further optics and it is extremely homogeneous. On the right, the intensity profile is shown as a function of the distance between the emitter and the target. The intensity profile stays very homogeneous up to a distance of 100mm. Since the beam is composed of hundreds of individual chips in groups, which can be individually addressed, it is possible to generate a dynamically changing beam profile.

The power density of the high-power VCSEL systems is 100W/cm2, with the possibility to increase this to more than 1kW/cm2 by the addition of micro-optics. VCSEL systems—compared to other lasers, even in the multi-kilowatt configurations—are very compact, rugged, easy to integrate, and offer cost advantages, making it easier to compete with non-laser heating solutions.

VCSELs in industrial processes

VCSELs, falling somewhere between traditional heating methods and lasers, have successfully been tested in a number of applications. Two examples in the field of plastic processing are discussed in greater detail below. Others include the firing of metallization lines on solar cells, now typically done in large ovens, and similar metallization processes in PCB, printed electronics, or battery manufacturing.

The VCSELs' intensity is also sufficient to locally increase the ductility of advanced high-strength steels (AHSSs), enabling stamping and rolling operations of these high performance steels. This is of special interest for the automotive industry, where the use of AHSS enables the design of lighter car bodies.

The ability to pattern the heat, for example, in roll-to-roll processes distinguishes VCSELs from other lasers and traditional heating sources. The VCSEL modules allow for individual switching and continuous control of the output power of the narrow laser zones they are composed of (FIGURE 2). Thereby, the heating profile all along the width of the module can be chosen arbitrarily and changed in time.

For example, to homogenize the heat distribution across a sample, either behind an oven process or as a stand-alone system, an easy fix to counteract heat loss along the edges is to illuminate along the edges with a higher intensity (FIGURE 2, center). Coupled with a thermal camera or a line of sensors, this process is further improved with closed-loop feedback that controls individual heating elements in the VCSEL source and adjusts the intensity profile on the work piece.

Metallization lines, surface coatings, or the activation of adhesives may require structured patterns. The individually addressable VCSEL chips can achieve this without additional optics, using a line with a varying intensity profile for a continuous process (FIGURE 2, right).

Laser heating for aircraft carbon fiber placement

Carbon fiber-reinforced plastic (CFRP) and other fiber-reinforced parts are state-of-the-art in the aerospace industry, and are slowly finding applications in the automotive industry. Currently, most complex composite parts are made with a thermoset matrix material. The parts are increasingly built by laying the fiber tape with an automated fiber placement system. Once built, the parts need to be cured in an autoclave, creating bottlenecks in the manufacturing line.

Moving to fiber-reinforced thermoplastic material can remove this bottleneck by using an automated fiber placement system with a high-energy heat source for in situ consolidation of the material. The ideal heat source for this application has a uniform distribution, and can be controlled in a closed-loop feedback process to keep the temperature stable throughout the tape-laying. While fiber and diode lasers have been used with good results, getting to a uniform square or rectangular intensity distribution requires additional optics, and their forte, high intensity as used in welding and cutting, isn't used at all.

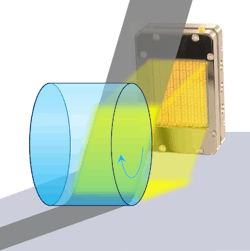

VCSEL systems fulfill all the requirements for in situ heating in an automated fiber placement system, without additional optics, and for lower cost than the fiber-delivered lasers. FIGURE 3 shows a setup that is currently being tested at the Fraunhofer IPT in Aachen, Germany.

FIGURE 3. A VCSEL system mounted at a carbon fiber placement head. (Courtesy of T. Weiler, AZL RWTH Aachen, and D. Werner, Fraunhofer IPT)

In tape-laying machines using more than one tape, the nature of the VCSEL systems allows sections of the beam to be turned off when not all tapes are used, leading to more flexibility in geometry. VCSEL laser systems will also be of special interest for thermoset automated tape laying, where the temperatures aren't too high but the process window is much smaller, requiring tighter control of the laser power and the intensity distribution.

Welding of microfluidic devices

Recent buzzwords in health news are personalized medicine and lab-on-a-chip. Microfluidic devices are involved that prepare DNA samples to be sequenced, or that enable performing one or more lab steps for medical diagnostics. New applications include standard blood tests, using just the blood from a pin prick rather than having blood drawn.

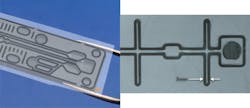

Manufacturing of microfluidic devices on a small scale is challenging. They usually consist of acrylic or polyester layers, of which at least one is structured. Lasers with good beam quality, equipped with scanners, are commonly used to weld selected areas together, or to activate the adhesive between the layers. The flexibility of the scanner setup allows for fast retooling, especially in the development cycle.

As this technology becomes mainstream, it's imperative to scale up manufacturing to very large quantities by making it fast and cost-effective. Using mask technologies and a light source that delivers high energy homogeneously to a large area allows welding of many devices in a few seconds, which is where VCSELs come into play again. Scalable to large areas and not requiring moving parts or additional optics, the VCSEL can be incorporated into welding systems. This enables processing trays of devices in a single shot, which is more cost-effective than using traditional laser sources (FIGURE 4).

Summary

Many industrial processes require heating for annealing, drying, melting, and curing. Currently, these are performed by a mixture of processes, from traditional ovens, gas torches, lamps, and hot air blowers to lasers modified to generate large spots. Traditional processing typically lacks the ability for a tight, closed-loop control of the temperature or the heat profile, but offer a cost advantage. Traditional lasers, generating very high intensities by design, can be cost-prohibitive for many of those applications, especially since additional optics are required.

VCSELs, a new generation of solid-state light sources, are unique photonics heating systems. Extremely compact and maintenance-free, their lower cost justifies replacement of traditional heating systems. Accurate control, homogeneous intensity distribution, and the ability to create heating patterns that can be changed in milliseconds offer a clear advantage over standard high-power laser systems modified to serve in heating applications.

REFERENCES

1. S. Pflüger, 'A high-power diode laser primer,' Industrial Laser Solutions, 29, 1, 28 (Jan/Feb. 2014).

2. H. Moench and G. Derra, 'High-power VCSEL systems,' Laser Technology Journal, Wiley, 2 (2014).

3. A. Pruijmboom, 'High-power VCSEL arrays make ideal industrial heating systems,' Laser Focus World, 50, 10, 19 (Oct. 2014).

GÜNTHER DERRA([email protected])is with Philips Photonics, Aachen, Germany; www.photonics.philips.com.