High-power diode lasers in metal processing

Larger spot size bridges gaps in brazing and welding

JÖRG NEUKUM

DILAS has populated the market with a series of turnkey diode laser systems for the past 20 years. Having started with direct beams, which are still in use for some special applications such as edge bonding in the furniture industry, they still find their niche applications. Now, fiber-coupled solutions are state-of-the art, allowing user-friendly integration of the laser system into production lines.

High-brightness approach

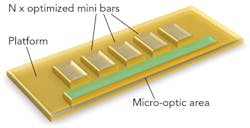

Scalable high-power diode laser modules, with a tailored mini-bar platform, can reach up to 2kW of fiber-coupled output. The setup (FIGURE 1) is schematically described as follows:

A number of optimized mini-bars are mounted and electrically isolated onto a platform, which at the same time acts as the mounting plane for a large number of micro-optical elements, as well as cold plate. The mini-bars are optimized in a chip structure with reduced thermal and electrical crosstalk, increased efficiency, and reduced divergence, allowing easy beam shaping for 22mm-mrad for further fiber coupling and in-front facet design (to cope with the higher intensities at the facets).

All mini-bars are mounted simultaneously. After this, all micro-optical elements for beam shaping are aligned actively and in full automation, resulting in modules with very consistent performance. Available up to 250W in 200μm-diameter, NA0.2 fiber, such modules are used to pump kilowatt-class fiber lasers by utilizing pump-combiner technology.

These platforms serve to build up beam-multiplexed modules with 2-, 4-, and 8-plate platforms (FIGURE 2), resulting in modules that can generate up to:

- 400W in 200μm-diameter, NA0.2 fiber;

- 800W in 200μm-diameter, NA0.2 fiber;

- 1500W in 300μm-diameter, NA0.2 fiber; and

- 2000W in 400μm-diameter, NA0.2 fiber.

Such modules are single-wavelength (915 or 976nm) and can be used for end-pumping fiber lasers as well as for materials processing, such as thin sheet metal welding and additive manufacturing, among other applications.

Thin sheet metal welding

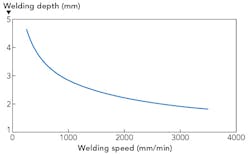

With the higher-power modules and systems of this series, thin sheet metal welding becomes feasible. FIGURE 3 shows the welding curve for an 18/10 chromium nickel (Cr-Ni; 1.4301) stainless steel sheet at a power level of 1200W, 300μm-diameter, NA0.2 fiber. The utilized processing head realizes a spot size of ~375μm-diameter. The inserted micro-section picture shows the weld at a 1.168mm-thick metal sheet and the dimensions of the weld bead at the upper and lower surface.

Welding of metal assemblies using continuous-wave laser radiation is an accepted method, ensuring productivity with a high degree of accuracy. Applications range from fine welding of electronic components, battery housings, sensors, pressure switches, or valves over to assemblies such as compensators, surgical instruments, pipes, and membranes.

High-quality welding seams also reduce cost and time requirements for reworking of parts. Depending on the application, reworking may be completely eliminated. Assemblies and parts with metal thicknesses below 1mm allow for the use of diode lasers with power levels well below 1kW.

In summary, the advantages include:

- High welding quality with little or no rework;

- No tool wear due to contactless process;

- Highest reliability with a maximum degree of flexibility;

- High welding speeds;

- Low cost of ownership and investment costs; and

- Locally defined thermal input and small thermal stress/warping of assemblies.

High-power approach

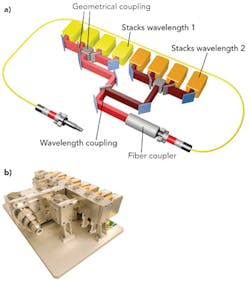

For applications requiring higher power but not the level of brightness previously described, the use of the mini-bar concept is too tedious and material-consuming. In applications such as cladding or hardening, there is no need for small fiber diameters—but for high power. Thus, the utilization of high-power diode laser bars with long cavities and high fill factor is well suited for this application. Using a similar approach with macro-channel, electrically isolated mounting and cooling, combined with automated beam shaping, stacks are produced that provide well above 1kW of optical output power. Because of automated beam shaping, the beams are very consistent and even interchangeable. Using spatial and polarization multiplexing for one wavelength together with wavelength multiplexing with other wavelengths, an alignment is reached to provide up to 8kW in 1000μm-diameter, NA0.2 fiber (FIGURE 4).

Turnkey systems, combined with driver electronics and cooling, can be used for additive manufacturing, cladding, brazing, or hardening applications, which are described in the following section.

Cladding and additive manufacturing

For example, the combination of a multi-kilowatt beam source with a powder nozzle allows the deposition of one or more layers of metal to generate wear-resistant layers for valve seats or drill heads. Further, it is used for repair welding of expensive tooling. The generation of 3D structures with high-power diode lasers and metal powder (additive manufacturing) now becomes more attractive and generates a new market used for prototyping and serial production.

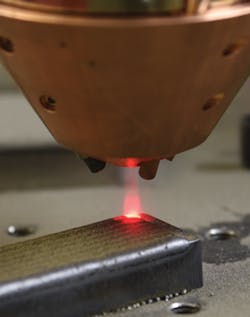

FIGURE 5 shows an in-process detail of a cladding sample, where the thickness of the added layer depends on the speed of the laser beam, as well as the amount of powder. The width of the clad layer also depends on the laser beam size and the homogeneity of the beam intensity. Parameters in the shown example were 3mm-diameter spot size at 2.5m/min, at a power level of approximately 3kW.

FIGURE 6 shows the generation of a ring structure onto an iron base. The powder nozzle in this case generates four streams of powder, which meet in the focal spot of the laser beam (lateral powder nozzle). The average grain size of the iron (Fe) powder is approximately 105μm. Process gases such as argon (Ar), argon helium (ArHe), or nitrogen (N2) are used, depending on the materials used.

The beam quality and power levels are well-suited for cladding applications since large areas can be treated simultaneously by using a homogenized line focus. With cladding, expensive tools can be reworked. Additive manufacturing allows the generation of lightweight, material-saving, complex structures that fulfill their strength requirements. This is being used in aircraft and automotive industries.

Brazing

In cladding and additive manufacturing, powder is used to generate the layers on top of a base material, whereas in brazing, two metals are joined using a filler material-often a brazing wire. The laser is used to heat up the wire material, which will then flow in between the two closely fitted joining materials. In contrast to welding, the joint materials are held together due to wetting by the molten wire (filler) material. Therefore, the joint materials do not necessarily need to be of the same material. Brazing also allows joining of dissimilar materials with considerable strength.

To join galvanized sheet steel as shown in FIGURE 7, a 1.6mm-diameter CuSi3 wire is used as filler material. The wire feed rate is at 4m/min. The focal spot of the laser can move with an independent speed; e.g., 6m/min.

Applications for brazing are mainly found in automotive industries, where the filler material is used to bridge the gap between two parts. Often, the filler material is galvanized afterwards together with the joined materials.

Hardening

Laser surface hardening can be used to enhance the longevity of metal parts that are exposed to stress, such as bearings or drill bits. Also, the hardening of knife edges or cutting dies is an established process in the tool industry. Heating with the laser and the rapid subsequent cooling provided by the ambient temperature leads to self-quenching of the material surface and to higher hardness than the bulk material.

In FIGURE 8, a homogenized 25mm wide laser beam has been used to treat C45E unalloyed steel for a machine building application. At a laser power of ~4.5kW and a speed of 1.2m/min, the image shows the heat-affected zone (~400μm) in a subsequent preparation of the material.

The hardness of the base material has been in the range of 218 HV1; the hardened region shows an increased hardness of up to 650 HV1.

Conclusion

With the availability of high-power diode laser systems in the kilowatt range, industrial high-brightness systems are being used for welding applications, whereas low-brightness devices are used in high-power applications such as cladding, additive manufacturing, brazing, and hardening. Often, the diode laser has significant advantages because of its inherent larger spot size (e.g., no need for wobbling a beam). The spot size also helps to bridge gaps in welding and brazing applications. Finally, the multiplexing of numerous wavelengths allows scalability of power levels for hardening or for cladding and additive manufacturing applications.

Dr. JÖRG NEUKUM([email protected]) is director, sales and marketing at DILAS Diodenlaser GmbH (Mainz, Germany), www.dilas.com.