Ultra short pulse (USP) lasers are currently enjoying high visibility in the world of industrial lasers as more companies jump into this arena and as specifications continue to expand while physical size and cost go down. At the recent Munich World of Photonics show, it was amazing to see all of the different offerings of USP lasers with output specifications across the spectrum.

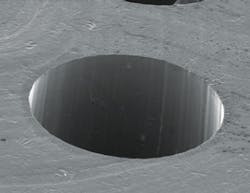

For the purposes of this article, USP lasers are defined as having a pulse length of <1 nanosecond (ns) and normally much shorter. It is well known that the key to clean, cost effective microprocessing with lasers is peak power intensity. This is achieved by using either a very short pulse, very high pulse energy, very small spot size, or a combination of all of them. When these conditions are optimized, clean processing can be achieved with near wavelength independence, even in otherwise wavelength "transparent" materials. The exact mechanisms are complex and are still a matter for some debate, but the result is clean laser processed parts with little or no post processing needed.

Lasers come in variations from continuous wave (CW), meaning the light is always on, to USP lasers where the light is only on for a relatively very short amount of time. For instance, if a laser pulse is 100 femtoseconds (fs) long, and the repetition rate of the laser is 100 KHz, the actual on-time of the laser is many orders of magnitude shorter than the off-time. To put things in perspective, transpose the coordinate system to one we can easily understand as humans. If 100 fs transposed to 1 second, then the next pulse comes approximately 3.5 years after the first pulse, or in other words the laser is off about 100 million times longer than it is on!

Company feedback

In preparation for this article, a questionnaire was presented to responsible persons at all the companies listed in TABLES 1 and 2, and their feedback has been correlated. It is by no means a complete survey, but it should include most of the major players in the laser machining market (apologies extended to anyone not included ... but your feedback is also welcome). The tables are divided into picosecond and femtosecond lasers, although in some cases there is a bit of overlap between the two. Placement in the Tables was dictated by the most standard product line, although custom systems are made by many companies with specifications exceeding those listed.

Picosecond lasers

TABLE 1 shows primarily vendors of picosecond lasers. The fundamental wavelength is 1064 nm in most all of the cases, arrived at by utilizing a number of different technologies. Commercially available output powers of up to 50 W are common, with hundreds of watts available from manufacturers like TRUMPF and Edgewave. Most of the responders indicated the availability of the second and third harmonics with conversion efficiencies in the neighborhood of 50% per step in almost all cases. Some vendors also provided the fourth harmonic, but these tend to be very expensive, and the optics degrade quite quickly compared to even the third harmonic.The table categories of Strengths and Future plans include smaller size, higher power, higher energy per pulse, shorter pulse lengths, and lower cost. In addition, a few of the vendors are looking into ways of improving the processing techniques outside of the laser by promoting applications work using faster scanners (which are a big limitation when trying to use very high rep rates) and supporting customers in their custom applications. This is pretty crucial—just because you have the best laser in the world, it does not mean you will automatically get the best processing results. One also needs correspondingly good system components such as optics, scanners, and software.

An interesting note is that Coherent (approaching $1 billion in yearly revenue) now offers two seemingly competitive products in the Talisker and Lumera models after the Lumera acquisition occurred at the end of last year. It is not clear to me how things will shape up in the future, but for now it seems like Lumera will address the high- and low-power requirements, while the Talisker will address the rest.

Femtosecond lasers

TABLE 2 shows primarily vendors of femtoseconds lasers. Output powers up to 25 W are available from most of the listed vendors with several hundred watts available using amplifier technology. The fundamental wavelength varies with the base technology, but it is mostly from 1028 to 1064 nm with the notable exceptions of Raydiance and Rofin. While there are probably benefits from using the longer fundamental wavelength, it does not lend itself well to higher harmonics as even at the quadrupled wavelength, it is still around 375 µm, not so far into the UV. There are a multitude of applications where this will not matter as long as the desired spot size can be achieved. Even with a complete 100% absorption of photons and no heat-affected zone (HAZ), simple physics limits the achievable spot size on target using infrared (IR) photons, so in those cases where the smallest spot size is needed, frequency conversion is important.

Most of the companies listed in this table also only make fs lasers, and their strengths list this long-standing expertise. While everyone is looking at lower cost, higher power, and smaller size, Spectra-Physics is looking for "disruptive" performance and, in order to really stand out from the crowd, this is probably what is needed, although it is not clear how to get there.As "Strengths," a few of the companies noted that they do not provide just the laser, but rather a complete turnkey solution—with an understanding of not only the lasers but the optics and applications. This is noteworthy because in many cases it is not clear to the average reader what one would do with, for instance, 400 W of femtosecond laser power. Also, how short in pulsing does one really need to go, and can it be done without compromising something else? As an example, because of the large bandwidth of extremely short pulse lasers (less than 100 fs), the optics become a challenge, especially for focusing to a small spot. Therefore, it may be beneficial to use pulses in the 150-200 fs range, which should be "short enough" for most applications while still not having to address optics concerns too strenuously. Markets for these lasers include medical device fabrication, cutting and scoring of glass, sapphire and other hard, brittle materials, and aerospace applications.

Other considerations

Finally, lead times and cost must be considered, both capital cost and operating costs, factors not specifically addressed because there are many to consider, including options, exchange rate, and discounts. However, most of the lasers listed cost between $250,000 and $350,000, with the higher-power laser (or extremely short-pulse lasers) costing more. Operating costs are hard to determine, but surely they are somewhat higher than for nanosecond lasers. Lead times vary from 8 to 10 weeks on standard products to 6 months or more on high-power products. On the other hand, some of the ps lasers especially are priced attractively. Ekspla and Attodyne, for instance, list as a strength a cost factor of 1/3 less than most competitors for similar specifications. This brings the cost very close to the cost for comparable nanosecond lasers, and it is clear that the cost difference will close very rapidly. Therefore, for the bulk of micromachining applications, it is not clear that nanosecond lasers will be needed much longer—especially when the cost differential becomes negligible.

Acknowledgments

Thanks to all of the companies listed and to the individuals who were kind enough to send both technical information on their products and figures, not all of which were used.

Ron Schaeffer

Ron Schaeffer, Ph.D., is a blogger and contributing editor, and a member of the Laser Focus World Editorial Advisory Board. He is an industry expert in the field of laser micromachining and was formerly Chief Executive Officer of PhotoMachining, Inc. He has been involved in laser manufacturing and materials processing for over 25 years, working in and starting small companies. He is an advisor and past member of the Board of Directors of the Laser Institute of America. He has a Ph.D. in Physical Chemistry from Lehigh University and did graduate work at the University of Paris. His book, Fundamentals of Laser Micromachining, is available from CRC Press.