Reproducible copper welding

Combining IR and green light is key

Christoph Ruettimann, Richard Bartlome, and Noémie Dury

More Industrial Laser Solutions Articles |

Laser welding in commercial furniture manufacturing Laser-GMA hybrid joining of thick high-strength steels |

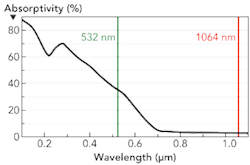

A prerequisite for laser material processing of copper is direct interaction between the focused laser radiation and the copper surface that requires part of the radiation to be absorbed at the surface. As FIGURE 1 shows, for a polished copper surface at room temperature, less than 5% of the laser radiation is absorbed (at 1 µm laser wavelength). Despite this, there are a range of measures that can be taken to allow copper to be welded successfully and efficiently, particularly with solid-state or fiber lasers.

The first of these measures is coating the surface with more absorbent metals, such as nickel or chromium, and mechanical preparation of the surface, for example, roughening or painting, also increases the absorption. However, both of these measures increase production costs as they require additional fabrication steps. Chemical impurities in the copper can also influence absorption behavior and make it more difficult to achieve a reproducible welding process. As can be seen from the absorption curve, shorter laser wavelengths would be an advantage. A diode laser (0.8 to 1 µm, infrared) or a frequency-doubled Nd:YAG laser (532 nm, green), for example, can deliver these wavelengths, although neither of these lasers has yet reached the stage where copper is industrially viable. Heating at the point of incidence of the laser radiation is faster or slower depending on the level of absorption, and the risks of overheating and splatter formation become unpredictable. The problem of poor reproducibility is even more pronounced for spot welding than for seam welding. Each individual laser pulse impinging on the cold copper material experiences different initial conditions. However, because the absorption depends not only on the wavelength and the surface characteristics, but also on the material temperature (absorption improves significantly at increased temperatures) and the intensity of the laser radiation, there is additional scope for improving the welding process.

Overlaying two wavelengths

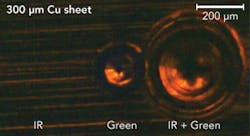

The poor reproducibility experienced in copper welding can be significantly improved by overlaying a laser pulse with a wavelength of 532 nm onto one with a wavelength of 1 µm. If the two laser beams are focused using the same chromatically compensated lens, it generally results in the copper surface heating up from the center to the edge of the weld spot. This is due to the better absorption of the green wavelength, thus raising the temperature of the copper and therefore raising the absorption of both wavelengths. With increased absorptivity, variations in the surface characteristics have a less significant impact. For example, if a laser beam is made up of 15% green and 85% IR and the different initial absorptions of the two wavelengths are taken into account, approximately the same quantities of energy from the green and IR radiation will be absorbed (at room temperature). FIGURE 2 shows pure IR welding (approx. 1 MW/cm2), pure green welding (approx. 1 MW/cm2), and welding with the combination of both wavelengths on a 300-µm-thick copper strip. The theoretical spot size is approximately 200 µm for both wavelengths. In the case of a pure IR pulse, no fusing of the copper surface is observed, while with a pure green pulse, some fusing can be seen. Overlaying the two pulses results in a significant enlargement of the weld pool.

Process details

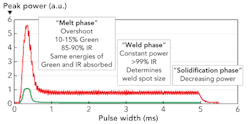

Choosing an appropriate IR pulse shape allows the relative green component, i.e., the conversion efficiency, to be adjusted. FIGURE 3 shows a typical IR pulse shape and the resulting green conversion. The laser pulse can be split into three phases, which are described in more detail below. At the beginning of the laser pulse (0.5 to 1 ms), the pulse intensity is deliberately set to ensure that the highest possible proportion of IR radiation is frequency-doubled. The combination of IR and green radiation heats the copper surface until the absorption is sufficiently high for IR, and the copper surface begins to melt. Typical values for the pulse power during the melting phase are between 0.5 and 2.0 kW, depending on the thickness of the copper strips. As soon as the copper begins to melt, the pulse power is sharply reduced. Although this means that very little green is then converted, the absorption of IR is high enough in the melting phase. From this point onwards, the welding is continued with IR only (negligible green component). The duration of the welding phase is determined by the extent and depth of the weld spot. At the end of the pulse, the power is reduced using a defined time constant to positively influence the cooling phase of the welding and thus its metallurgical and mechanical properties (for example, hardness).

Comparison with pure IR welding

FIGURE 4 shows a comparison between pure IR welding and welding with IR and green laser light. The pulse duration was ~1 ms, and no pulse shaping was used (rectangular pulses). The weld spots in the upper half of the figure were made using IR pulses with a 0.8 kW pulse power, while the weld spots in the lower half were created with 1 kW IR and 0.1 kW green. As expected, the reproducibility of the pure IR welding is very poor, and significant fluctuations in diameter and even missing weld spots can be observed. The reproducibility of the welds with IR and green light is considerably better. No defects can be identified. The insert in FIGURE 4 shows a series of weld spots created using the pulse form described in FIGURE 3. The weld spots achieved using this method look almost identical. A more precise analysis reveals that the variation in the weld spot diameter is well below 10%, and 100% full-penetration welding was achieved from the copper ribbon to the base material. This figure meets the strict specifications of medical applications, for example.

Efficiency considerations

In a further investigation, the melting threshold intensities of pure IR, pure green, and a mixture of both types of radiation were determined and compared. TABLE 1 summarizes the measured melting threshold intensities. Although the melting intensity for pure green radiation is the lowest, the frequency conversion represents a significant limitation on process efficiency. However, if a mixture is used instead of pure IR radiation, the melting threshold is practically halved for identical laser efficiency and thus represents an effective increase in process efficiency.

Industrial implementation and application examples

The Lasag SLS GX 1500 laser is equipped with the patented GreenMix technology. Unlike other industrial green laser concepts, this solution uses only one laser source, which naturally decreases investment costs of the system. Both wavelengths are transported onto the copper surface using optical fibers and a dedicated processing head. TABLE 2 summarizes the technical specificatuons of the GreenMix Laser.

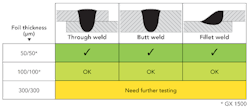

Various industrial applications can be addressed with the GreenMix laser. Currently the working range of the laser is restricted to component dimensions below 300 µm. FIGURE 5 summarizes this laser's working range for different joint configurations. R&D work is ongoing to push the limits of the working range to component sizes of 0.5 mm and above.

Some classical real-world applications of this laser are: ribbon bonding for medical applications (e.g., pacemakers); wire bonding (e.g., lead frames on heat sinks) and wire separation for the electronics industry and mobile devices; and contacting of solar modules (e.g., flexible cells) for the photovoltaics industry.

Summary

This article describes methods that significantly improved the reproducibility of laser welding of copper materials. The combination of IR and green light using intelligent pulse shaping not only results in improved reproducibility of the welds, it also brings about a considerable increase in process efficiency. ✺

Dr. Christoph Ruettimann([email protected]) is the head of research and development, Dr. Richard Bartlome is project manager for optics and optomechanics, and Noémie Dury is the head of laser application at Rofin-Lasag in Thun, Switzerland.

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles