A wide variety of industries can benefit

Frédéric Mermet

Laser surface functionalization refers to the process of using laser techniques to endow a surface with a particular property. Laser techniques include marking, engraving, ablation, micromachining, and additive manufacturing.

At IREPA Laser, Strasbourg, France, researchers have developed the experimental micromachining system called the MUSE platform (Micro Usinage Système Expérimentale), which is dedicated to texturing applications. This Class 1 machine houses a femtosecond and a nanosecond laser, allowing processing with pulses from 300 fs up to 240 ns in the near-infrared wavelength band and from 300 fs up to 10 ps at wavelengths in the visible (green) and ultraviolet. Of the work described in the following, the MUSE was used (only) for sharkskin.

The MUSE platform has four mechanical axes, three optical axes, and associated galvo heads, microscope lens, and one cutting head. This system offers a 300 × 300mm working area and permits a focus point from 1 to 100 µm. The associated driver software features include a display of the depth and dimensions of processed area.

Car personalization

IREPA has undertaken work to evaluate the aesthetic potential of laser surface treatment of polymer decorative materials used in automobile interiors (PVC, TPO, PP, and PU) without reducing wear and ultraviolet (UV) behavior. The properties achieved with three laser wavelengths (10.6 µm, 1 µm, and 0.35 µm) and three marking patterns were investigated. FIGURE 1 shows a selection of results, all of which were tested for wear and UV resistance.

The project has now been transferred to an integrator to implement a machine prototype. Although the UV laser treatment results showed a wider range of effects and better accuracy, the 1-µm fiber laser offered the best compromise because of its easy industrialization.

Fuel injector

The challenge here was to create a grip effect between a metallic and an elastomer piece while preventing any leaking problems. The contact area in question is identified in FIGURE 2a. To respond to our client requirements, IREPA developed a process to apply appropriate textures on the cylindrical part: lines, zigzag (FIGURE 2b), or dots cloud. Surprisingly, the process optimization favored the creation of burrs for improved grip. All textures were produced in a cycle time scale from 13 to 26 s/part. The part entirely textured is shown in FIGURE 2c.

Critical points were the software optimization of pattern overlap and the reliability and reproducibility of burr formation. Functional improvements were achieved, and two laser systems have been installed in production lines.

Cycling performance

The challenge in this study was to improve the aerodynamic performances of a bicycle wheel by texturing the sidewalls of the tire. By using a CO2 laser, high-resolution patterns could be engraved directly onto the polymer, obviating the need to manufacture a series of molds (FIGURE 3).

Having identified the most efficient texture (i.e., minimum drag), the tires are produced by injection molding. It is claimed that this innovative product allowed competitors to gain 60 s on a 40 km ride at a speed of 50 km/hr.

A bio-inspired application: sharkskin

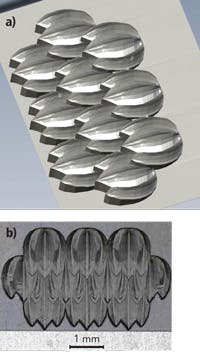

The LATEXDRED project objective was to develop a textile with shark scales (see FIGURE 4) for swimwear applications. Efforts to replicate the sharkskin pattern have been undertaken by femtosecond laser ablation directly on textile and on stainless steel (for pattern impression).

The sharkskin characterization is now complete and textile machining is underway. CAD file generation is in progress, and the first tests on stainless steel have been undertaken (see FIGURE 5). This project will end in 2014.

This brief article on potential industrial applications for laser surface functionalization gives some indication of the wide variety of industries that can benefit from this process. ✺

Frédéric Mermet ([email protected]) is the microprocessing manager at IREPA Laser, Strasbourg, France.

Reprinted from Issue 69 (Spring 2013) of The Laser User with the permission of the author and the AILU.

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles