Remote laser welding benefits a variety of production applications

Technology advances allow welding complex parts in high volumes

TIM MORRIS

With today's high-brightness, multi-kilowatt solid-state laser sources, the concept of remote laser welding with a standoff up to several hundred millimeters became widely feasible in industrial welding applications. For this, scanning optics are steering the beam in a 2D space through a pair of high-speed, galvanometer-driven mirrors (x and y) and, in the case of 3D applications, a fast focusing mechanism quickly adapts the focus distance (z). These systems are capable of guiding a laser spot with high precision and can relocate the spot to any position in their work envelope within a few milliseconds. If the work envelope of scanner optics is inadequate to cover the desired area to be welded, an industrial articulated arm robot can be used to guide the scan head. The working range can be extended to cover large work pieces and to access them under well-defined inclination angles.

Recent advancements in scanner optical configurations, scanner controls, and real-time interfaces to optical sensors have significantly expanded the application of remote laser welding. A wide variety of optical magnifications are available to optimize the optics to the specific laser power and beam quality desired for a particular application. A previously unavailable optical zoom function that allows a variable spot size at focus is now available in scanners such as the SCANLAB intelliWELD II. Scanner controllers are available with intuitive user interfaces and full integration with the guiding robot's motion planning, making the previously cumbersome task of programming complicated weld programs simple and user-friendly.

Historically, these systems have been implemented primarily for lap welding of sheet metal components. In recent years, manufacturers have exploited the benefits of remote laser welding to more efficiently weld a number of challenging applications. The following production scenarios have benefited from remote laser welding, achieving levels of precision and productivity not possible with more conventional welding techniques.

Static remote laser welding

In its simplest form, remote laser welding can be implemented with fixed-position 2D and 3D scanners. Often referred to as static remote laser welding, the scanner is rigidly mounted in a fixed location, the un-welded assembly is located within the scanner field, and the only motion during welding is via the scanner optic.

A rapidly growing application area for static remote welding is the assembly of lithium battery modules for e-mobility. These batteries require welding of individual battery cells, as well as packaging of multi-cell assemblies. These can be complex assemblies of various materials (copper, aluminum, nickel, and nickel-plated copper) and multiple layers in a wide range of thicknesses. Lasers are ideal for most of these welding requirements, and scanners have proven to be a valuable tool in maximizing speed and accuracy while providing highly flexible weld geometries.

One example is the welding of the BMW i8 battery modules. BMW engineers were faced with the challenge of increasing the tensile strength of the welds connecting the pressure plate to the frame of the aluminum battery module, while maintaining the seam quality. This was achieved by implementing scanner welding with different oscillation patterns. Dr. Rüdiger Daub, Manufacturing Technologies and Prototype Shop Electric Energy Storage at BMW, reported that by combining longitudinal and transverse oscillations, the tensile strength was increased by 35% and porosity was decreased by 40% [1]. The applied Blackbird Robotics scan solution (based on intelliWELD) maximizes flexibility in terms of both high mirror dynamics (with frequencies of several hundred hertz) and full control of the heat input with freely programmable oscillation patterns and power modulation along the oscillation pattern.

With full Cartesian calibration of the scan field and integrated drift compensation, even highly position-critical welds can be executed by scan heads at high speeds. Welding of heat exchangers for automotive exhaust assemblies involves welding thin tubes to thin sheets on both ends (tube bundles; FIGURE 1). The components are precision-stamped thin wall parts and the weld joint is a butt-edge weld where the tube meets the sheet at each end. A typical configuration is 16 tubes per tube bundle. Weil Engineering GmbH (Muellheim, Germany) determined that the ideal optic for laser welding these assemblies is a 2D scan head (SCANLAB intelliSCAN FT), which allows high-speed, accurate placement of the laser beam and has sufficient range of motion to weld the entire assembly without moving the optic.

The challenge is locating the laser beam precisely at the intersection of the tube and sheet. The parts themselves are extremely repeatable—however, variation in the location of the assembly is greater than the repeatability required for welding because of the tolerance stack-up of the tooling and indexing mechanism. Therefore, accurately locating each assembly prior to welding was required.

The solution was to incorporate a camera-based vision system (Blackbird ScannerVisionSystem) to detect key tube sheet features. This image is sent to the Blackbird Robotics scanner controller (SCU), compared to the previously recorded nominal assembly location and the scanner program is offset in x, y, and rotation around the z-axis to align the weld path to the assembly's actual position. This is all done in under 300ms prior to welding of each assembly. These heat exchangers, in multiple-shift production since 2012, were the first application of this solution. Since then, numerous 2D and 3D applications have profited from this combination of speed and accuracy.

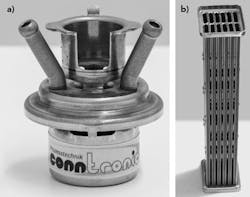

Conntronic Prozess- und Automatisierungstechnik GmbH (Augsburg, Germany) encountered the challenge of welding the automatic dossier module (aDM), which is a cooling housing that supports VW's BlueMotion technology initiatives. BlueMotion is a range of innovative energy-saving technologies, including advanced engines that reduce fuel consumption and harmful emissions. The aDM is a complicated mechanical housing that requires three different material thicknesses to be assembled together with an air-tight seal while minimizing distortion (FIGURE 1). The company evaluated a number of alternative welding solutions, ultimately selecting scanner-based remote laser welding because of its ability to minimize robotic motion and, therefore, cycle time, as well as its ability to precisely weld small-diameter (6mm) circles and the overall flexibility that long-focal-length optics provide for less-restrictive tooling designs. The keys to success here were the Blackbird Robotics system's tight integration to the robot control for programming, and again the accuracy achieved via the 3D calibrated scan field and integrated drift compensation of the galvanometers. The robotically mounted intelliWELD scanner solution from Blackbird Robotics has been in production for the aDM modules since 2012, and is currently producing them at a rate of 650,000 pieces per year.

3D welding on-the-fly

Combining the speed and accuracy of a galvanometer-based scanner system with the motion range of an articulate arm robot can bring significant productivity enhancements to remote welding applications. When coordinating the motion of the scanner with the robot, these capabilities are maximized. In the "Welding On-The-Fly" mode of operation, the robot guides the scan head on a smooth trajectory, while all high-speed movements are executed by the much-faster scan axes. With this method, laser-on times of 90% or more can be realized. Experience has shown that a single weld using remote laser welding can be made in as little as 20% of the time required to make an equivalent weld using conventional joining methods (e.g., resistance spot welding, riveting, and fixed-optic laser welding) [2].

With suitable controls, on-the-fly welding can be implemented in a highly productive manner. State-of-the art systems allow for full synchronization with the robot motion, and provide an optimized motion planning of the scan head and the robot axes. Typically, lap welding applications with a multitude of short welds distributed throughout a part have been targeted with this approach. In the past, this application was limited to simple and flat parts like seat backs. With the advancement of control technology in recent years, more complex parts (such as seat structures, cross car beams, and automotive doors) have been successfully implemented with Blackbird's 3D on-the-fly welding solutions. This solution has enabled weld speeds to be maximized (>10m/min) and jump times to be minimized (<20ms) for complex 3D parts, while still ensuring access at proper inclination angles to the weld positions through the part tooling.

The ever-present challenge of allowing a path for zinc vaporization when welding galvanized materials must also be addressed. To ensure a stable process, the zinc gas released during welding has to be given a way to evacuate from between the sheets. A number of different production-proven approaches can be observed.

Aside from providing designed-in spacing features on the parts or clamping techniques that create a defined gap between the sheets, the most common method is dimpling. In this two-step approach, during a first run, short laser pulses of a few milliseconds are applied to create small bumps with a typical height of 0.1–0.2mm on the surface of the lower sheet. These then serve as spacers towards the upper sheet, which is welded to the lower sheet in a second step.

More recently, the technique often referred to as "laser screw welding" or "laser spot welding" has been developed, which aims to more directly replace resistance spot welding. This technique combines the typical laser welding advantages of higher processing speeds, single-sided access, and low heat input, along with being more tolerant of gaps between sheets and requiring no pre-weld dimpling for galvanized materials.

A few years ago, BMW, in cooperation with Blackbird, was motivated to deviate from conventional techniques of overlap laser welding automotive doors. Their goal was to implement lap fillet seams to allow smaller flanges and other process advantages, such as zero-gap welding of galvanized material. The challenge of extending the application scope of remote laser welding to fillet seams was to develop a fully coaxial approach for seam tracking through scan heads. The resulting system has been qualified for industrial use and initially implemented in serial production of BMW MINI doors since 2014 (FIGURE 2).

The production solution consists of remote welding systems and controls from Blackbird, together with a coaxial camera for seam tracking. The result was an enhanced scan system with coaxial illumination and online seam tracking functionality. For the first time, the system combined the advantages known from on-the-fly scanner welding with the requirements of position-critical weld configurations:

- Robust seam tracking with a typical accuracy of 0.1mm;

- High flexibility through omnidirectional processing;

- Maximum efficiency via minimized repositioning times and robot movement; and

- Improved weld joint accessibility through long standoff from the work piece (~0.5m).

Future outlook

Scanner technology continues to advance, enabling further visibility and control of the welding process. Optical coherence tomography (OCT) is expected to provide a next leap forward in this respect, as it is a single-point measurement approach that can gather distance data on a micrometer scale at frequencies in the kilohertz region. In principle, it is an interferometer setup with one beam path (measurement arm) directed at the work piece, and a second beam path of known length (reference arm). State-of-the-art implementations of this sensor in fixed laser-optic heads have recently been introduced to the market (e.g., Precitec IDM). This interferometer uses a superluminescent diode with a wavelength in the near-infrared range and fiber-coupled beam delivery.

Together with suitable beam steering of the measurement beam, the following measurement tasks can be enabled:

- Pre-process: Seam finding ahead of the welding laser;

- In-process: Measurements in the melt pool area or inside the keyhole; and

- Post-process: Topography measurement of the weld seam.

Work is currently underway to fully integrate OCT technology with Blackbird's scanner welding solutions based on the intelliWELD 3D scan heads. The following challenges are being addressed for this:

- A second x-y scan system coupled into the observation port of the welding scan head to enable scanning the measurement beam in a truly calibrated manner;

- A focusing mechanism for the measurement beam that matches the speed of the welding heads' z-axis; and

- An integrated software and control environment that allows setup of the seam tracking or measurement task in a convenient and implicit way during programming of the weld figures.

In the first implementation, this will allow seam tracking ahead of the weld zone and for post-weld topography measurement. The initial data taken on a first prototype system (FIGURE 3) promises to result in an optical system with unprecedented capabilities in this regard, with pilot systems scheduled to be placed in the field in the coming months.

Remote laser welding is a highly productive processing method, which is enabled by the seamless control integration of optical scan heads, industrial robots, and optical sensors. Historically, it was primarily used to replace resistance spot welding of overlap joints in automotive components (such as hang-on parts and seats). With the current state-of-the-art scanners and software control capabilities, the application scope of remote welding has been extended to enable welding of a variety of complex high-volume components, with new applications continuing to emerge.

REFERENCES

[1] R. Daub, B. Nitschke, and A. Heckert, "Laser welding with beam oscillation," EALA 2015, Bad Nauheim, Germany (2015).

[2] M. Pälmer, "Laser application in manufacturing aluminum doors for the new Mercedes Benz S-Class," EALA 2014, Bad Nauheim, Germany (2014).

TIM MORRIS([email protected]) is VP of sales and service for Blackbird Robotics, Inc., Sterling Heights, MI; www.blackbird-robotics.de.