Paint and other coatings on aircraft serve many purposes, including corrosion protection, erosion resistance, camouflage, radar absorption, and corporate branding. Regardless of their purpose, these coatings require replacement from time to time—sometimes frequently, but usually every 5–8 years. The current dominant method of depainting for both military and commercial aircraft is chemical removal, which brings with it a variety of undesirable characteristics. Laser paint stripping is finally emerging as a credible, economical, and "green" alternative.

Background

More than 35 years ago, the US Air Force (USAF) Logistics Command began to investigate alternative solutions to chemical and mechanical paint removal from military aircraft. The list of negatives concerning chemical depainting is long, including:

- The requirement to mask sensitive areas of the fuselage prior to chemical application;

- The requirement for personal protective equipment to handle the chemicals;

- Large water usage to rinse chemicals from aircraft;

- Large multiplication of hazardous waste volume;

- Release of carcinogenic hexavalent chrome primer into the waste stream;

- Personnel exposure to hazardous chemicals;

- The inability to use on aircraft wings because of chemical ingress;

- The requirement to de-mask prior to painting; and

- The cost of hazardous waste disposal.

Additionally, the requirement that manual sanding be performed on sensitive wing areas brings with it another set of problems, including high frequency of operator repetitive injuries, operator exposure to hexavalent chrome, the potential for damage to aircraft wing surfaces, and the lack of qualified operators.

It is no surprise that alternatives to these depainting methods have been sought for many years. As early as 1980, the USAF studied The Future of Aircraft Paint Removal Methods [1], with particular interest in laser paint stripping. In the late 1980s, a flurry of USAF-sponsored work was carried out in search of the right laser and the right deployment means to address this challenge.

Now, three decades and many, many millions of research dollars later, laser paint stripping is finally emerging as a credible solution to replace the hazardous, environmentally unfriendly, chemical, and mechanical paint stripping methods that dominate aircraft depainting today. And, surprisingly, the boldest new initiative in laser paint stripping is being spearheaded by private industry.

The laser paint stripping process

Laser paint stripping has often been described as an "ablation" process, but it more closely resembles "vaporization" and consequent combustion of the paint. To prevent thermal damage to the aircraft surface, the laser energy must be delivered rapidly and briefly, either by pulsing the laser beam or by sweeping a continuous laser beam across the painted surface. In either case, the top layer of paint is heated and then vaporizes, followed by immediate combustion as it leaves the surface and encounters oxygen in the air. The heat of combustion in laser paint stripping can be many times higher than the laser energy deposited to the surface, and efficient removal of this heated effluent is essential for process efficiency and workplace safety.

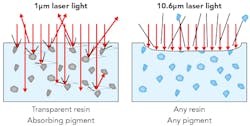

All paints do not absorb laser energy the same way, and all laser wavelengths are not absorbed the same way by paints. FIGURE 1 shows the two means by which laser energy (1μm from solid-state lasers vs. 10.6μm from CO2 lasers) is absorbed by paints. If the paint is comprised of transparent resin with a dark pigment, like typical military gray paint, then a 1μm beam can be delivered into the depth of the painted surface and absorbed along the way by the dark pigment. This process can be very efficient. However, if the paint is white, the pigment is highly scattering to the 1μm beam, and the process is essentially prevented from operating. On the other hand, a CO2 laser beam can successfully remove any color of paint since the laser energy is absorbed at the outermost surface and does not transmit through the thickness. This ability of CO2 laser paint stripping becomes additionally important if removal of primer is required—a function that is quite difficult for the shorter wavelength to accomplish.

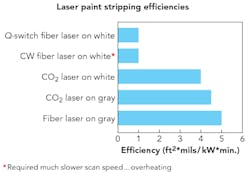

The efficiency of laser paint stripping performance is measured as Volume of Paint Removed/Energy Delivered for Removal, and the specific units (as initiated by the Air Force many decades ago) are:

Ft 2*mils / kW*min (where mils are thousandths of an inch)

This metric (along with actual laser power) is extremely important in understanding productivity, thermal loading on the aircraft, and overall process cost. Values for this metric on different paints with different lasers are shown in FIGURE 2.Beam to the work

There are several major elements in delivering a laser paint stripping beam to the work surface. The first requirement is that the beam be delivered from a ground location to a scanner, which is located at the end of a robot capable of reaching the heights of a full-scale aircraft. This beam delivery task would be most easily accomplished with a fiber. However, given that the majority of aircraft surfaces are colors other than gray, it is obvious that a color-independent process should be adopted. This latter consideration presents an obvious dilemma since it has just been shown that fiber-delivered laser power is far less efficient on light colors. And, at least for now, the new Q-switched, fiber-delivered lasers are not nearly as powerful as commercially available CO2 lasers, and cannot be delivered via long fibers.

So, the 10.6μm CO2 laser is the obvious choice. On the other hand, successful delivery of a CO2 laser beam along tens of meters of beam path requires that many functions be provided, including circular polarization, collimation for a long beam delivery, beam path cleanliness (particulate and gaseous), and beam path alignment compensation for changes in CO2 laser output pointing, robot platform distortion, and robot arm(s) distortion.

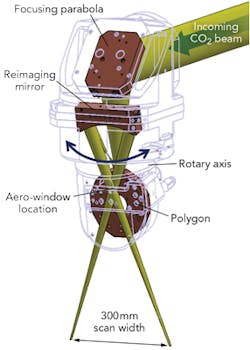

Fortunately, a proprietary automatic beam alignment system has been developed to enable delivery of up to 30kW of laser power through the 12 mirrors necessary to reach the next beam delivery element—the polygon scanner (FIGURE 3). This major element in delivering the beam to the work surface was developed by EWI as a response to the limited capabilities of competing galvo scanners. The relative benefits of the polygon scanner include use with any laser wavelength at powers up to at least 30kW; higher scan speed than galvos, with uniform scan velocity, lower flame height during stripping, more efficient combustion of effluent, lower heat input to the work surface, and better viewing for process control; an aero-window that eliminates the need for a fragile, transparent window; and the highest efficiencies and productivity ever reported.The polygon scanner has only one moving part—the polygon itself. The stationary mirrors are water-cooled, and the polygon is gas-cooled. Typical scan velocity across the work surface is 45m/s, and the latest scanner design provides a 300mm swath for paint removal. Typical travel speeds for the motion of the scanner are 100–200+ mm/s. The scanner system is equipped with a patented process vision system, which monitors the color and location of the approaching surface to be stripped as well as that of the as-stripped surface. Finally, an effluent removal system is provided to improve stripping efficiency, facilitate vision, and prevent contaminant release to the surrounding environment. Laser paint stripping is the only depainting process that reduces the volume of hazardous waste.

Delivering the process

Despite the feeling we may have inside one, commercial aircraft are actually quite large. The length of an Airbus 380 is 73m, its tail is 24.1m above the ground, and the aircraft offers about 4000m2 of paint to be stripped. Manipulating the scanner and its paint stripping process around an object this size requires a mobile robot with eight degrees of freedom from any particular fixed location, and another two degrees of freedom to reposition the robot from location to location, around the aircraft and within the hangar. Since the robot (FIGURE 4) and its base need to be quite large to be able to reach all the aircraft surfaces, the added weight and size of a 20–30kW TRUMPF CO2 laser is a manageable challenge.The mobile paint stripping robot is equipped with many sensors, hardware, and software systems to provide operational and safety functions, including (but certainly not limited to):

- Preprogrammed aircraft surface information;

- Precision location of aircraft within the hangar;

- Robot base locating/positioning within the hangar;

- Personnel safety light sensors for moving robot axes;

- Area scanning to avoid robot contact with aircraft;

- Light scanning and contact sensors on end-effector;

- Aircraft surface profilometry;

- Aircraft surface temperature;

- Real-time process control for pass overlap and paint thickness variation; and

- Multiple software-based safety systems.

The software challenges presented by these safety considerations, in addition to control of the robot motion, laser, scanner, and beam alignment systems, are daunting. Fortunately, the development team's primary systems design organization, Southwest Research Institute, has extensive previous experience in the design and implementation of large-scale robotics for media blast aircraft depainting.

It takes a team

The overall project development, design, building, financing, marketing, and management of this laser paint stripping effort represent a substantial technical and business challenge, and could not have been attempted by a single entity. Instead, a global collection of corporate and government organizations has been assembled to accomplish the goal of laser paint stripping for large-scale aircraft [2]:

- LR Systems BV: global project management and financing;

- The Southwest Research Institute: primary system design, assembly, and test;

- EWI: the laser scanner and beam delivery developer;

- TRUMPF: custom 20kW CO2 laser supplier;

- NTS Group: mobile robot systems manufacturer;

- The Netherlands Aerospace Laboratory: laser paint stripping process validation;

- Singapore Airlines (SIAEC): validation partner (lead customer);

- HIT BV: risk mitigation analysis;

- The Netherlands Government: innovation funding support; and

- Multiple AF bases and military research organizations: military and commercial advisory boards.

Laser paint stripping offers a cost-effective alternative to the hazardous, environmentally unfriendly, current practices for military and commercial aircraft depainting. The laser power and scale of the mobile laser paint stripping robot described here dwarf all previous efforts in terms of productivity and sizes of aircraft capable of being stripped. Other potential non-aircraft areas of applications include aerospace, transportation, marine, and public infrastructure. Business cases for potential laser applications depend on maximum process efficiency and deliverable laser power. It takes a multi-talented, committed project team to undertake an effort of this scale and complexity.

REFERENCES

1. See www.dtic.mil/dtic/tr/fulltext/u2/a214946.pdf.

2. See http://lrsystems.com.

Stan Ream | Technology Leader, Lasers and Fuel Cells at EWI

Stan Ream is an internationally recognized expert in industrial lasers, process development and analysis, and manufacturing systems design and performance. As laser technology leader at EWI (Columbus, OH), Stan focuses his experience on solutions to the joining challenges facing all EWI industry sectors.