Laser cutting meets today's airbag business challenges

Laser cutting quality approaches zero defects while maintaining profitability and competitiveness

PIERRE-MICHEL RICHER

The recent, massive airbag recall has brought into sharp focus the necessity of incorporating stringent quality standards into airbag manufacturing. The safety issues impacting these life-saving devices have come to symbolize the erosion of consumer trust that has resulted from the relentless cost pressure placed on suppliers. To win public confidence, original equipment manufacturers (OEMs) are taking extraordinary steps to guarantee vehicle passenger safety. These drastic new measures aimed at increasing the level of airbag quality control introduce additional challenges for the tier-1 suppliers, who remain focused on reducing their cost per bag in a continually changing airbag supply ecosystem.

An increasingly complex market

With light vehicle production set to grow by 4% annually until 2020, the airbag market in particular is projected to expand by a compound annual growth rate (CAGR) of 8.1% per year. This is partially because of an overall growth shift attributable to new safety regulations in India, China, and other developing countries. Emerging economies are expected to account for 58% of the total number of vehicles produced worldwide by 2020. China alone will account for 30%, surpassing Western Europe and North America in commercial and passenger vehicle production.

For mature markets, increasing levels of passive safety will result in more widespread distribution of new types of airbags, with as many as 12 applications in a single premium vehicle. Driver-side, passenger, and side-curtain airbags are standard on most new vehicles, with many passenger cars and light trucks outfitted with eight or more airbags. Airbag dimensions continue to evolve as well, as consumer car safety testing bodies like the New Car Assessment Program (NCAP; see sidebar) issue recommendations advocating for larger, wider side-impact airbags.

Innovative new airbag applications continue to emerge both inside and outside the vehicle. Volvo and Land Rover now offer pedestrian airbags for select vehicle models sold on the European market. Active between speeds of 20 to 50km/h, they are designed to minimize impact in some frontal collisions. Other concepts still in development include front-seat-mounted and roof-mounted rear airbags.

Industry challenges

Since the fallout from the airbag inflator scandal, stringent measures have been imposed by carmakers to reinforce the inspection of airbag igniter system components. Automated inspection systems enable suppliers to ensure their components meet rigorous safety standards without slowing production.

For the fabric component of the airbag, the type of inflator used often determines the choice of material. In similar fashion, automated vision inspection has become a vital part of the quality monitoring process. Carmakers now require many airbag suppliers to install scanners and vision systems to perform dimensional control of cut pieces for cut-and-sew airbags. This ensures that all cut features are present, without the inadvertent introduction of additional cuts.

However, the reinforced measures only add to the complexity of the manufacturing process. Despite these new developments, airbag suppliers must nevertheless maintain the same cost target to turn a profit. Airbag manufacturers are reaching the limits of cost optimization and are looking for a way out of the downward cost spiral. This explains why so many manufacturers are now resorting to cheaper materials like polyester fiber. However, the lower cost is not without its drawbacks, as these materials are often characterized by a high level of distortion because of their relevant elasticity.

Improving the road safety value chain

When combined with process and resource optimization, state-of-the-art laser cutting technology can help airbag manufacturers overcome these multipronged business challenges. Advanced airbag design and cutting techniques enable these exacting new requirements to be met to achieve end quality approaching zero defects, even when using cost-efficient material like polyester. By improving their productivity and efficiency, suppliers can achieve the gains to remain competitive while also meeting the OEMs' increasingly demanding requirements.

Identification of an anomaly during the production process can translate into substantial losses in downtime or costly re-cuts, especially when vehicle-occupant safety is at stake. New airbag pre-production software is designed to standardize the complete production process by enabling verification at each step of the airbag fabric prepping process.

Because the geometry of cut parts comes from industrial design departments, in various formats, the first step is to check the consistency of units and scales. A second step entails the removal of all geometries not necessary for cutting, even those invisible to the naked eye. Powerful wizards detect and flag them, eliminating the risk of cutting a 1/10mm hole in the center of an airbag. For multi-ply cutting, the third step consists of optimizing fabric use while guaranteeing cutting quality. For one-piece-woven (OPW) airbags, the next step is to build the grid, prepare for SmartCutting, and assemble the parts from the industrial loom layout. Before the first cut is even made, the necessary data are extracted in minutes.

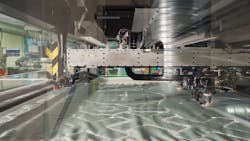

Multi-ply laser cutting at high speed

Cutting through a thick stack of cut-and-sew material without fusing the layers using a high-power laser beam at high speeds and 2g acceleration requires dynamic laser power control with pinpoint accuracy. Indeed, the cut is made through matter sublimation, but this can be achieved only if the laser-beam power level can be accurately adjusted in real time. When the intensity is inadequate, parts are not properly cut. And when the intensity is too powerful, the layers can bunch up and cause a build-up of fiber particles between the layers. Next-generation laser cutters can manage laser power intensity to the nearest watt and microsecond (FIGURE 1). What's more, several factors can be taken into account, such as the nature of the material to be cut, the geometry of shapes, speed, and acceleration. Cuts made a fraction of a second beforehand can also be taken into account to adjust for the slightly elevated temperature that runs the risk of fusing material in the adjacent area. This is precisely the risk posed by tangent lines, which are cut by a single path to ensure flawless quality.

Cutting path correction for airbags free of defects

In theory, all that it takes to cut an OPW airbag is the designation of a starting point and the outline of the cutting path for consistency with the desired template. This would be the only operation to perform if the material itself were completely regular. However, because cost-efficient polyester is more elastic than other fibers, weaving and post-treatment of the material can cause bowing and skewing in all or part of the pieces. The cutting path must therefore accommodate this distortion at the risk of making a cut inside the bag.

It is equally important for certain features to be positioned with precise spacing that maintains the center-to-center distance, such as mounting holes. These complex issues can now be addressed with ease using next-generation cutting preparation software. By delimiting specific areas of the OPW bag design that may not be altered, the cutter takes account of these rules by instantaneously adapting the geometry of each cutout to the real contours of the fabric (FIGURE 2), while at the same time adhering to rules governing positioning and spacing. It is this dynamic interaction between the airbag cutting preparation software and cutter that results in SmartCutting, which produces cut pieces identical to the dimensions of the verification template, with constant system capability—even when cutting highly distorted material.

Production is the step where profits or losses occur. With the right pre-production software and the latest laser cutting technology, airbag manufacturers can reduce their cost per unit while producing airbags free of defects the first time around, contributing to the road safety value chain.

ACKNOWLEDGEMENT

SmartCutting is a proprietary technology developed by Lectra to correct OPW cutting paths in the instance of material distortion.

PIERRE-MICHEL RICHER([email protected]) is the automotive product manager for Lectra, Paris, France; www.lectra.com.

What is NCAP?

The National Highway Traffic Safety Administration (NHTSA) is an organization under the U.S. Department of Transportation (DOT), whose mission is to save lives, prevent injuries, and reduce economic costs because of road traffic crashes through education, research, safety standards, and enforcement activity. The New Car Assessment Program (NCAP) provides consumers with important information in making a new car purchase—and for comparable vehicle models, it provides a direct comparison of the crash-worthiness of vehicles. Information from this program also exists on the required labels on each new vehicle for sale.

NCAP rates vehicles to determine crash worthiness and rollover safety. The safety ratings are gathered during controlled crash and rollover tests conducted at NHTSA research facilities. Vehicles with a rating of five stars indicate the highest safety rating, whereas one star indicates the lowest rating.