Laser welding of auto exhaust systems finds footing in United States

The United States automotive market place is undeniably unique. For 32 years, the best-selling vehicle in the US has been the Ford F-150, a 5500-lb., V8-powered pickup truck popular for farmers, small businesses, and suburban families alike. To an outsider, it might seem that the US is not concerned about fuel economy, but over the last decade that has finally started to change. Gas prices started to climb significantly about 10 years ago and for many years, the US government has been tightening mandated fuel economy regulations known as the Corporate Average Fuel Economy (CAFE) standards. Even the current glut of low-priced oil won't make the government backtrack on these standards, which were implemented in an effort to protect the environment. Car designers have been looking for improvements in fuel economy in every aspect of their design.

The first wave of mileage improvements was substantial: changing from body-on frame to unit-body designs and downsizing engines from V8s to V6s and from V6s to 4 cylinders across the marketplace, without major impacts on performance. Also in the first revolution of changes were automatic transmissions with 6, 8, 9, or 10 gears. Who would have thought that an automatic transmission could ever offer better acceleration and fuel economy than a manual transmission? Even Ford's best-selling truck—almost always sold with a V8—has changed to an aluminum body and is becoming popular with their Ecoboost V6 Turbo. US consumers and car manufacturers are paying attention to fuel economy and changing the automotive landscape.

Now, the big "low-hanging fruit" design changes are mostly done and engineers are looking to squeeze every gram of weight out of every passenger vehicle. If one compares the typical 3500-lb. weight of sedans designed by the American "Big 3" (Chrysler, Ford, and General Motors) to the 3223-lb. weight of Asian-designed sedans also built in America, you can quickly see the US has a way to go.

Laser welding of exhaust systems

It's known that laser welding can play a big part in weight reduction, as it is already widespread in body and chassis applications to allow engineers to reduce the mass of metal required in each welded joint. They can utilize smaller overlaps and tabs for laser welding than that needed for spot welding. Plus, laser welding doesn't require access to the back side of the weld. These same advantages are starting to be adopted in the exhaust system.

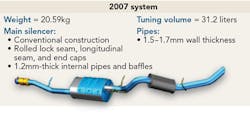

The last generation of silencers was typically made from stamped components with lock-seamed longitudinal seams, and end caps that were attached with either lock seams or overlap welds (FIGURE 1). A traditional lock seam has four layers of material overlapped and locked together for at least 3/8 or 1/2in. of overlap across the entire shell, wasting material and increasing mass. The stamped end caps had to be recessed into the end of the muffler to have a sufficient overlap for a seam lock or overlap weld, increasing mass and reducing tuning volume. Laser welding came to the rescue: in the exhaust system specifically, laser welding allows the elimination of lock seams and overlap welds while achieving lower emission leak rates.

New car designs raise exhaust system problems

Interestingly, as modern car designs evolve, exhaust system engineers are faced with a particular set of juxtaposed challenges:

- As with all other parts of the car, the weight of the exhaust system has to be reduced to improve fuel economy—make it lighter.

- Engine down-speeding through the use of taller gear ratios lowers the frequencies that need to be attenuated, resulting in the need for larger average tuning volumes. These larger silencers would traditionally require more packaging space—make it larger inside.

- Increased use of hybrid electric powertrains requires packaging space for the battery packs, reducing the packaging space available for the exhaust system—make it smaller outside.

- Increased adoptions of all-wheel drive systems also reduce the space available for the exhaust system, and complicate the pipe designs—keep it out of our way.

Transition to laser welding

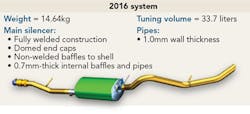

Laser welding in the exhaust system has been utilized for many years, primarily in the commercial truck field. There, lower volumes and larger-diameter components, compared to passenger car exhausts, make it difficult or uneconomical to get suitable round shells unless they are custom-made by roll formers and longitudinal seam welders. So, the technology is readily available to use butt-welded exhaust components, and the high volumes of the passenger car world are well served by the high speeds of laser welding. Roll-formed silencers offer more volume than stamped shells with their inset ribs. Butt-welded silencers weigh less than lock-seamed or overlap-welded units, and don't have an obvious potential leak point where the can meets the end cap. Domed end caps welded to the silencer offer more tuning volume and less weight.

Additionally, laminated mufflers are in favor at some of the world's largest automakers. Making the silencer shell from two thinner pieces of stainless steel can offer improved sound attenuation over a single-wall silencer, and allows selection of materials with different anti-corrosion properties for the inside and outside of the silencer. Laser welding fits right in, being able to butt-seam-weld both layers at the same time with a cosmetically attractive weld and no weld strength problems.Modern silencers have shells, heads, and reduced baffle thicknesses (FIGURE 2), as well as:

- Welded seams to eliminate lock seams;

- Some muffler shells will be two layers of 0.5mm material;

- Some single-layer shells will have material as thin as 0.6mm;

- In the case of deep-drawn heads, starting thickness may be 1.2mm;

- Dimpled muffler shells will help suppress radiated noise;

- Baffles are already at 0.8mm and will likely go thinner; and

- Nonstructural passage tubes will be 0.6mm or thinner.

Catalytic converters

Catalytic converters, known as "hot ends," can also benefit from laser welding, and are perhaps a little ahead in adopting more modern manufacturing techniques. Clamshell converter shells with overlap weld joints seem to be losing ground to tubular butt-welded designs, whether done by TIG or laser. This reduces their mass and required packaging space while eliminating the need for hard tooling. A laser-welded converter shell can also have its ends spun down to the pipe diameter as long as it receives a little post-weld processing such as annealing or seam planishing.

Tube welding

Another place where laser welding offers advantages to exhaust system designers is in fabricating the internal pipes that connect the different chambers of the silencer. Traditionally, these will be made by placing solid tubes onto a purpose-built "punching" machine that will use die-less punching to put holes in the pipe. But the mechanical tooling can be difficult to maintain and will leave the punch burr on the inside of the tube, which can cause a whistling noise in operation.

Laser welding tubes out of pre-punched steel coils allows making any desired hole pattern while placing the burr on the outside of the tube.

Today, silencer manufacturers still use lock seams on their silencers in North America, while European manufacturers have been quicker to adopt laser welding. As the weight reduction, tuning volume, leak rates, and quality standards continue to push their design, laser welding offers a unique set of advantages to address the future demands on exhaust system design.

Dan Robinson | Vice President of Sales, Weil Engineering North America

Dan Robinson is vice president of sales for Weil Engineering North America (Novi, MI).