by Andrew Cockburn, Matthew Bray, and William O'Neill

LCS can reduce process costs and increase application range

Laser based technologies such as laser cladding and laser alloying use a laser to melt and fuse metallic powder into a coating on a track-by-track basis. However, there are drawbacks associated with these processes where the effect of high process temperatures, solidification shrinkage, and coating dilution must be considered in order to avoid component distortion, high residual stresses, and unwanted intermetallic phases.1

FIGURE 1. Schematic of LCS system.

Alternatively, thermally sprayed coatings have been used to deposit a wide variety of materials from light alloys to metal carbides. While thermal spray can suffer from the problems described above, coatings may also contain a significant portion of oxide and have structures that require a remelting step before the desired density and coating properties are achieved.2

Cold Spray (CS) aims to overcome these problems by depositing coatings without melting the powder particles. In CS, powder is accelerated in a supersonic gas jet before it impacts the substrate. On impact the particles undergo significant plastic deformation, which leads to localized heating and flash welding at the interface.3

This technique can be used to produce both coatings and 3D objects4 and can deposit pure metals such as aluminum, copper, and tantalum and composite coatings such as Al-Al2O3 and Co-WC.3, 5 Because of its cold deposition mechanism, when compared with thermal spray or laser based processes, CS offers low oxide content, a lack of thermally induced stresses, and the ability to coat a variety of substrates including polymer composites, while allowing deposition rates of up to 5kg per hour.4

There are inherent problems associated with the 'cold' mechanism of deposition. Operating costs are high because large volumes of helium, with its high speed of sound, or gas heaters that consume up to 50kW of power are required to allow powder particles to reach speeds approaching 1000ms-1, required for deposition.6 In addition, bond strength and density are reduced when depositing hard materials, such as Ti alloys, and CS coatings generally have large compressive residual stresses. High operating costs and a limited range of materials have restricted the number of applications for which CS is economically viable.

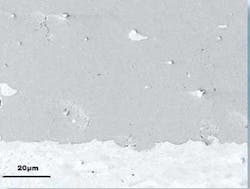

FIGURE 3. Titanium coating deposited onto a titanium substrate at 1250mm min-1 using 30 bar nitrogen and 1kW laser power.

Laser assisted Cold Spray

Laser assisted Cold Spray (LCS)7 has been developed to widen the range of materials that can be deposited using nitrogen and eliminate the need for gas heating, dramatically reducing process costs and increasing the range of applications for which CS may prove attractive.

It has been recognized previously8 that increasing particle temperature can lead to an increase in deposition efficiency and reduce the critical deposition velocity as a result of particle softening. Increased deposition temperature may also help to overcome issues of low bond strength in CS coatings, which have been attributed to the extremely short timescales available for bonding to occur.9 However, increased gas temperatures heighten the risk of nozzle fouling when spraying low-melting-point metals such as aluminum.10 A method of heating the powder outside the nozzle is required.

In LCS, a laser heats the deposition site to between 30 and 80 percent of particle melting point.11 This significantly reduces particle strength, and allows the particles to deform and build up a coating although they only impact the substrate at velocities around half those used in CS (< 500ms-1). Reducing the need for high velocities enables the use of cold nitrogen as the process gas, thus reducing expenditure from $23 per minute for helium to around $0.23 per minute and reducing power consumption through the elimination of the gas heater. This reduction in capital and operating costs means that LCS may be suitable for many applications for which CS has proved too costly, allowing the fully solid process route found in cold spray to find use in a broad range of applications.

LCS system

The LCS system (see Figure 1) consists of a high-pressure (10–30 bar) nitrogen gas supply that is split and sent to a converging–diverging (de Laval) nozzle, both directly and via a high-pressure powder feeder, where metal powder particles are entrained within it. The two streams recombine and pass through the nozzle where they are accelerated to supersonic speeds. The high-velocity, powder-laden gas jet exits the nozzle and is directed towards a substrate. The powder stream impacts a region of the substrate that is simultaneously illuminated by a 980nm, 1kW diode laser. Laser power is controlled by a closed-loop feedback system that uses an infrared pyrometer to monitor deposition zone temperature.

In the test system currently in use, the de Laval nozzle, laser head, and pyrometer are housed within a light-tight build chamber (see Figure 2). The nozzle, laser head, and pyrometer are held stationary on the ceiling of the chamber while the substrate is free to move on a CNC-controlled X-Y table during deposition. By linking laser power to pyrometer readings, deposition site temperature can be controlled to within 50°C of target during operation.

Coatings

Coatings have been produced from a variety of materials including 316L stainless steel, aluminum, titanium, and Al-Ti composite powders in order to tune the LCS system, characterize the LCS process, and determine the range of operating temperature and particle velocity over which optimal coatings are produced.

Titanium coatings have been examined in detail because they are of interest in the biomedical field where their corrosion resistance and biocompatibility make them an attractive choice as an implant material. A typical 2.5mm-thick titanium coating produced at a traverse rate of 1.25m min-1 is shown in Figure 3. Although the coating has been deposited onto a cold, thin (1mm) substrate, no distortion is observed, confirming that the non-molten process route found in LCS results in low residual stress, allowing the coating of thin sections without substrate preheating. Coating adhesion is dependent on the substrate and coating material selected but has been shown to be in excess of that found in CS, with glue failure at a stress of 50MPa being recorded for pull off tests on 316L coatings.

Examination of polished cross sections (see Figure 4) reveals that the tracks deposited are dense (<0.5% porosity), with no visible oxide present. Chemical analysis has confirmed the later observation. Although the deposition site is heated, oxygen and nitrogen levels remain similar to the CP2 grade titanium sheet analyzed for comparison. The degree of substrate deformation observed is greater than that found in CS coatings, indicating that the use of the laser has resulted in significant substrate softening.

FIGURE 5. Optical micrograph showing a LCS coating produced from mixed aluminum and titanium powder.

Spraying mixed powders (see Figure 5) demonstrates that LCS is capable of producing composite coatings with constituents of differing hardness. Although little deformation of the hard phase can be observed, the more ductile aluminum deforms around it, allowing a dense coating to be formed. This effect will be exploited to expand the range of materials that can be processed using LCS in order to enable coatings for wear-based applications to be deposited.

Future directions

Work is currently underway to prove the suitability of the LCS process for the deposition of hard facing materials and composite coatings that are currently processed via laser cladding. The use of LCS will enable coatings to be deposited onto thin sections, which are difficult to process with current technologies due to the potential for distortion caused by solidification shrinkage.

References

1. R.Vilar, "Laser cladding," Journal of Laser Applications, 1999, 11(2): p. 64-79.

2. R. Gonzalez, et al., "Microstructural Study of NiCrBSi coatings obtained by different processes," Wear, 2007(263):p. 619-624.

3. T. Stoltenhoff, H. Kreye, and H.J. Richter, "An analysis of the cold spray process and its coatings," Journal of Thermal Spray Technology, 2002, 11(4): p. 542-550.

4. J. Pattison, et al., "Cold gas dynamic manufacturing: A non-thermal approach to freeform fabrication," International Journal of Machine Tools and Manufacture, 2007, 47(3-4): p. 627-634

5. R.S. Lima, et al., "Microstructural characteristics of cold-sprayed nanostructured WC-Co coatings," Thin Solid Films, 2002, 416(1-2): p. 129-135.

6. R. Morgan, et al., "Analysis of cold gas dynamically sprayed aluminum deposits," Materials Letters, 2004, 58(7-8): p. 1317-1320.

7. M. Bray, S. Celotto, and W. O'Neill, "Development of a laser assisted material spraying process," Proceedings of the International Congress on Applications of Laser and Electro-Optics (ICALEO 06), Laser Institute of America, Arizona, USA, 2006: p. 103-109.

8. R.C. Dykhuizen and R.A. Neiser, "Optimizing the cold spray process," in ITSC 2003: ASM International.

9. H. Assadi, et al., "Bonding mechanism in cold gas spraying," Acta Materialia, 2003. 51(15): p. 4379-4394.

10. T. Stoltenhoff, et al., "Optimization of the cold spray process," in ITSC 2003: ASM International.

11. V. Champagne, The Cold Spray Materials Deposition Process, ed. V.K. Champagne. 2007: Woodhead Publishing.

The authors are with the Centre for Industrial Photonics, Institute for Manufacturing, Department of Engineering, University of Cambridge, Cambridge, UK. Contact Andrew Cockburn at [email protected].