Laser cutting can tailor graphene properties

Porriño, Ponteverde, Spain - Graphene, a single atomic-thick sheet of honeycomb carbon lattice, is a promising material for new electronic circuitry, sensors, and optical communications devices. With unique electronic and optical properties, the material brings a new era of fast, reliable, low-power communication and information processing.

However, there is no large-scale technology to control graphene's properties. Researchers from the Technological Center AIMEN are exploring the use of ultrafast lasers as a tool for graphene processing, where a precisely focused laser beam can be used to tailor the properties of graphene films in finely defined areas to produce distinct behaviors useful for making these devices.

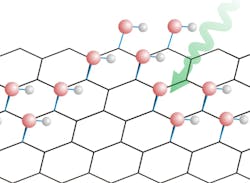

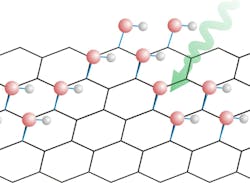

The key is to use short, highly controlled laser pulses to induce chemical changes in the carbon lattice—a single pulse with a duration of several picoseconds. Researchers demonstrate that they can pattern graphene lattice by laser cutting, adding external molecules or binding compounds. With a laser spot focused in areas of one square micron or less, direct writing of devices on graphene can be done with high precision, producing nano-devices with minimal footprint and maximum efficiency.

AIMEN researchers have demonstrated the laser-based, large-scale patterning of graphene at high speed and resolution. For low energy inputs, multiphoton absorption plays a major role, inducing chemical reactions between carbon and atmosphere molecules and resulting in new optical properties in graphene.

Functionalized graphene is just starting to be recognized, and the full industrial potential of this technology needs to be tackled. AIMEN’s research work lays a foundation for deep understanding of the chemical and physical processes for industrially feasible graphene patterning. They have over 45 years of experience in materials science and technology, and industrial R&D in a wide spectrum of applications.

For more information, contact Dr. Ivan Bobrinetskiy at [email protected].