Tampere, Finland - Laser and glass welding technology developer Primoceler has signed a contract with the European Space Agency to design and manufacture complete CMOS sensor packages for orbital missions. Working with Primoceler on this contract will be ON Semiconductor.

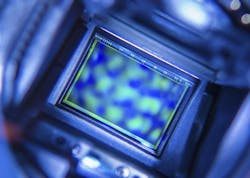

Based on ON Semiconductor's HAS3 hermetic design, CMOS sensors are encased in an impermeable seam of glass using laser welding technology, which helps to avoid any problems due to thermal changes.

"Hermeticity testing from a US laboratory proves that our glass weld has better than <6,0x10-12 atmcc3/s Kr-85 leakage rate, well exceeding the current military and aerospace standards," explains Ville Hevonkorpi, general manager at Primoceler.

In February 2014, the company celebrated its selection as the developer and fabricator of optical sensor packages for ESA orbital missions. It partnered with ON Semiconductor to engineer a solution that far exceeded the agency's exacting requirements for hermeticity. Now, the two companies are developing a new hermetic package design for a coming HAS3 CMOS sensor and for future products.

The primary challenge with orbital missions is fabricating hardware that can protect sensitive electronics for the long term while also enduring rapid temperature and pressure changes, not to mention the vacuum of space. Glass welding meets those demands, offering a fully hermetic seal of all components along with an extremely small heat-affected zone during the welding process.

Outside of CMOS sensors for ESA orbital missions, Primoceler's welding technology has practical applications for the healthcare, military, and consumer electronics sectors, among others. The company has also begun conversations with interested parties in Australia and several European nations.

For more information, please visit http://primoceler.com.