Welding is a laser application that, historically, represents about 15 percent of the total units sold each year. Considering that laser installations have grown at an average rate of about 15 percent per year since 1970, welding has just kept pace, while other applications such as cutting and marking have, in recent years, each reached around 33 percent of the annual installations.

This apparent lower acceptance rate is not cause for concern because welding is, for the most part, very much a part-sensitive process. Think about it, whereas sheet metal cutting applications are pretty much the same around the world, laser welding is material and design specific. Outside of a select few applications, laser welding is not a process that generates large volumes of equipment sales for a specific product, globally. One exception could be in the automotive sector, namely, body-in-white spot welding.

Industry observers have speculated on the potential that could arise if laser welding were to replace conventional resistance spot welding. No less an authority than Frank Di Pietro, retired director, manufacturing engineering, General Motors Corporation, has long been an advocate for laser spot welding in body-in-white operations. However he, like many other laser enthusiasts, recognized that, until recently, the laser could not match the speed and cost effectiveness of resistance spot welding. Recent developments, in the form of remote spot welding, have changed that equation so that the laser process now offers users an alternative to a technology that dates back to World War I, when Ford first implemented resistance spot welding in an on-line assembly operation.

Speaking for remote laser welding Di Pietro says, it will "revolutionize automotive and industrial welding applications worldwide. The technology is 'production ready' now, with successful proven applications at Volkswagen, Fiat, Daimler Chrysler and supplier plants."

Responding to the question of why laser welding has been so successful in a few short years, he answers succinctly, "flexibility and speed." He says these factors have resulted in reductions in both investment and operating costs, as well as other benefits in improved weld quality and increased throughput with reduction in tooling and floor space requirements. For example, he cites a report presented at last March's Automotive Laser Applications Workshop that described a six-fold increase in welding speeds, from three seconds for each resistance spot weld to only a half second for each equivalent remote laser weld, or from 20 welds/minute to 120 welds/minute.

He says that in resistance spot welding, the tooling functions and the welding systems are totally integrated, resulting in dedicated and inflexible production subsystems. Whereas, in remote laser welding, the tooling and welding systems are separate, independent functions, resulting in total flexibility for manufacturing operations.

Di Pietro speculates that remote laser welding will be applied in auto body assembly plants, high-volume welded sub-assemblies in metal stamping plants, mechanical components at supplier plants and the list goes on. As he says, "The future potential of remote laser welding has only just begun."

There are a number of suppliers working in the field of laser remote welding. Among the companies working in remote laser welding applications and equipment, two responded to our invitation and submitted information on their work. Their reports follow.

Robotic remote laser welding with high-power Nd:YAG laser

Annett Klotzbach, Veiko Fleischer, Thomas Schwarz, Lothar Morgenthal, Eckhard Beyer

High-power laser welding is now a well-established technology in car body manufacturing. Often the laser welding process takes the place of resistance spot welding processes. For example, remote welding systems are well suited for reducing the positioning time of stitch welding applications. For CO2 systems, a remote welding system consists of a gantry-style multiaxis motion system and a beam scanning head. A long focal length is used for laser welding, which allows the distance between the beam manipulating element and the workpiece to be as large as 4-5 ft typically. One or two tilting mirrors reflect the beam and generate highly dynamic laser spot motion in a workspace of about 4 × 4 × 2 ft3.However, there are some inherent difficulties in using gantry-style remote welding systems. The accessibility of all welds must be taken into account. The angle of incidence changes between 0-40° and influences the result of the laser weld, and the welding process with CO2 laser radiation is more sensitive to plasma formation instability.

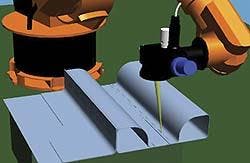

At the Fraunhofer Institute for Material and Beam Technology, a remote welding system for Nd:YAG lasers up to 4 kW has been developed. It consists of beam deflection optics and a standard motion system, for example a conventional industrial robot. The beam deflection optics (Lasertronic) includes two galvo-driven tilting mirrors and a dynamic focusing optic. The mirrors guide the beam accurately and quickly along the prescribed path over a workspace of about 100 mm2. Due to the low inertia of the tilting mirrors, the motion of the beam spot on the work surface can reach velocities of 600 m/min and accelerations can reach several tens of gs.

To increase the work area, the beam deflection optics is coupled with a conventional robot handling system. The synchronization of the robot and the mirror motion of the beam deflection optics permit the laser spot to follow any path within the workspace of the robot with high accuracy. In places where the agility and accuracy of the robot limits the process, the beam deflection optics take over.

Comparable to remote welding systems for CO2 lasers, the Coupled Axes System (CAS), consisting of robot and beam deflection optics, has access to every weld the robot can reach. The range of angle of incidence can be decreased by moving the optics within the robot. Additionally, by using a Nd:YAG laser source, the benefits of its process stability can be realized.

Applications

The CAS opens new application fields to laser beam welding, especially in car body manufacturing. For example, considerable time can be saved by replacing resistance spot welding with laser stitch welding. One requirement of this process is optimized path planning. This means creating a smooth robot path with as little acceleration as possible (and therefore a high average path velocity) and making use of the high agility of the beam deflection optics to reduce positioning time in moving between separate weld seams.

With a conventional motion system and 6 m/min welding rate, the time required for completing a 1m-stitch weld seam with 50 equally spaced 10mm seam segments is 10 seconds. With the coupled axes system developed here, the same weld seam can be obtained within 5.25 seconds, a reduction in processing time of 45 percent. The reduction in stitch weld processing time is achieved because the beam deflection optics are able to move the laser spot between seam segments within a few milliseconds. The robot is able to move along its own path at a velocity of nearly 12 m/min, while the necessary welding rate of 6 m/min is realized by countermotion of the beam deflection optics.

The authors are with the Fraunhofer Institute for Material and Beam Technology, Dresden, Germany. For more information e-mail to [email protected].

Remote laser welding: concepts from Trumpf

Frank J. Brennan

This innovative and unique means of high-speed welding was first brought to the automotive community by California-based Optical Engineering in March 1997. The concept demonstrated that combining a high beam quality CO2 laser with galvo-controlled scanning optics allowed for incredibly high welding rates, compared to more traditional, typically, resistance welding.

Given the excitement that the technology generated, one would think that remote welding could have been implemented throughout the industry. A number of factors slowed the integration of remote laser welding. Among them are: the difficulties of presenting cover gas at the weld spot, the issues involved in requiring a "line of sight" to the workpiece from the galvo head, certain materials make coupling of the beam difficult, for example, aluminum and the limited availability of systems builders familiar with the technology.

As a laser manufacturer, Trumpf was not prepared to address all of these issues. Some of the answers to these issues are best driven by the tooling houses, which take the remote welder and wrap a "system" of tooling, automation, controls and enclosures. But Trumpf was prepared to develop technology that expands the capability of the remote laser welder. Earlier this year, Trumpf presented a high beam quality 5kW CO2 laser for typical sheet metal welding

The laser of choice is a standard 5kW Trumpf product with very high beam quality (meaning an M2 of 2, good enough to provide for very long focal lengths). The laser beam is delivered to a scanner head, which incorporates two high-speed, linear-driven optics, which, working in tandem, will steer the beam to the workpiece.

The first-generation release product offers a working envelope of 30 X 30 inches in the X- and Y-axis and 20 inches in the Z. Any three-dimensional product that can fit in this cube can be laser welded.

Tooling issues, as noted previously, present the biggest challenge. While the scanner can weld in milliseconds, cover gas for the weld is required. New concepts in tubular tooling allow for cover gas to be distributed at the weld zones as part of the clamping fixture.

Examples of this welding process follow.

Behr (Stuttgart, Germany) needed to make multiple welds on a heat exchanger used in both passenger car and truck models. The design of the part had requirements of many crosshatch welds, 6mm x 13.5mm, assembling the end caps to the part. Successfully integrated, the user has produced more than 2.5 million parts to date.

At BMW scanner-welding technology is used to weld an engine compartment subassembly. The previous process utilized standard resistance welding, which produced 23 spot welds in 30 seconds. Retooling with the scanner allowed for 23 half-inch stitch welds in 5 seconds.

This new laser welding technology provides several advantages: almost 100 percent "beam on" during the weld process, no significant unproductive time due to the very high "jump" speed weld-to-weld, and the ability to spread the welding across the part, allowing thermal distortion control and very high speeds and acceleration.

Frank Brennan is laser sales manager for Trumpf, Plymouth, MI. Contact him at Tel. (734) 354-9770.

About the Author

David Belforte

Contributing Editor

David Belforte (1932-2023) was an internationally recognized authority on industrial laser materials processing and had been actively involved in this technology for more than 50 years. His consulting business, Belforte Associates, served clients interested in advanced manufacturing applications. David held degrees in Chemistry and Production Technology from Northeastern University (Boston, MA). As a researcher, he conducted basic studies in material synthesis for high-temperature applications and held increasingly important positions with companies involved with high-technology materials processing. He co-founded a company that introduced several firsts in advanced welding technology and equipment. David's career in lasers started with the commercialization of the first industrial solid-state laser and a compact CO2 laser for sheet-metal cutting. For several years, he led the development of very high power CO2 lasers for welding and surface treating applications. In addition to consulting, David was the Founder and Editor-in-Chief of Industrial Laser Solutions magazine (1986-2022) and contributed to other laser publications, including Laser Focus World. He retired from Laser Focus World in late June 2022.