Researchers at the Fraunhofer Institute for Laser Technology (ILT; Aachen, Germany) have developed a processing technique that now makes it possible to work with difficult materials using selective laser melting (SLM). To combat heavy smoke formation, a new process chamber featuring optimized shielding gas flow was developed in cooperation with ILT spinoff Aconity3D for use with magnesium alloys. In addition, processes for use with copper alloys were optimized, as were special systems with high-temperature preheating for use with crack-prone and difficult-to-weld metals.

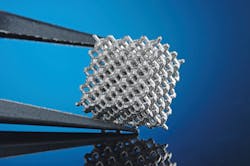

Selective laser melting with magnesium—which is 30% lighter than aluminum—can be used to produce resorbable implants, making it desirable for use in lightweight construction and medical technology applications. Desirable features of implants, such as tailored designs and complex structures, can be produced at no extra expense using SLM. As a material, magnesium offers the added advantage of being resorbable by the human body. Implants based on solid magnesium materials are already in use, but further benefits are promised for implants with pore structure. The idea here is that new bony material will grow into the implant, while at the same time the metallic material is resorbed by the body. So the Fraunhofer ILT researchers developed an SLM process for magnesium alloy implants of this type, in which both the exact shape and pore size of the implant can be chosen. The biocompatibility of the implant prototypes has already been demonstrated in vitro.

To explore their SLM technique in detail, the research team constructed a motorcycle triple clamp in 1:4 scale by optimizing the entire topology of the component by computer. Their objective was to achieve full structural and weight optimization for comparable lightweight parts. This opens the door to new applications not only in lightweight construction, but also in medical technology, such as custom-made surgical bone replacements for cranio maxillofacial applications.In addition to magnesium alloys, research work is continuing on developing SLM for processing novel materials such as high-temperature alloys for turbomachinery applications or copper alloys. The various processes will be exhibited at the International Laser Technology Congress 2016 (AKL'16) in Aachen.

For more information, please visit www.ilt.fraunhofer.de.