Laser processes could have utility in reworking CFRP aircraft parts

To more efficiently rework aircraft components made of carbon-fiber reinforced plastics (CFRPs), Laser Zentrum Hannover (LZH; Hannover, Germany) has started a joint research project, dubbed ReWork, together with project partners INVENT (Braunschweig, Germany), OWITA (Lemgo, Germany), and Precitec Optronik (Neu-Isenburg, Germany). The goal of the project is to develop a reliable process for thin-walled and complex CFRP components.

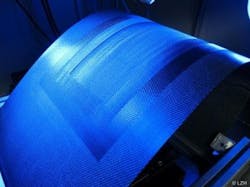

Today, many aircraft components are made of lightweight CFRP, which has low weight and high stability. However, processing this material is still difficult. The aircraft industry requires a reliable solution to eliminate production- and operation-related defects in a faster and more cost-efficient way.

Laser processes offer promising approaches to eliminating defective areas by custom-fit patches, as carbon fiber tissue can be contact-processed without force and wear. Moreover, a laser's high geometric resolution makes it possible to scarf the surface precisely and to insert custom-fit replacement patches. During patch repair, the defective areas are removed layer by layer using a laser, and then replaced by a custom-fit patch.

An innovative system consisting of a laser, scanner, short-coherence interferometry system, and control software determines the individual process parameters according to the shape of the component. The short-coherence interferometry system measures the depth spatially with high resolution, ensuring precise layer-by-layer removal. In that way, surface deformations because of local increases in thickness, which occur frequently during mechanical processing, can be avoided.

Apart from the proper system technology, the LZH Production and Systems Department's Composites Group focuses on further development of the laser process. One challenge during the laser-based surface post-treatment of CFRP aircraft components is their thin-walled and complex shape that requires individually adapted laser parameters.

CFRP typically has a spatially inhomogeneous thermal conduction--therefore, to achieve a constant surface quality, LZH experts are inventing a sophisticated process strategy and also considering the geometric scalability of the process parameter. The new technology could also be usable for 2D and 3D components, ideally with the possibility for automation.

The ReWork project (which stands for "Reliable reworking on thin-walled, curved CFRP surfaces using photonic systems and piezo-assisted quality control") is being sponsored by the German Federal Ministry of Economics and Energy (BMWi; Berlin, Germany) for a duration of three years.

For more information, please visit www.lzh.de.