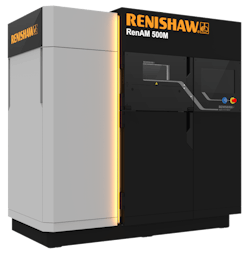

Metal additive manufacturing system

Renishaw (Wotton-under-Edge, Gloucestershire, England)'s RenAM 500M additive manufacturing system builds complex metallic components directly from CAD using metal powder bed fusion technology. The machine manufactures parts within the 250 x 250 x 350mm build volume, and uses a high-power ytterbium fiber laser to fuse fine metallic powders together, creating functional 3D parts. A patented high-capacity twin SafeChange filter system enables builds to run for long periods in a stable and controlled atmosphere, and an intelligent control system actively senses the filter's condition and redirects the gas circuit to a clean filter before conditions deteriorate. Powder sieving and recirculation are automatically carried out within the compact system, reducing the need for manual handling and exposure to materials.

For more information, please visit www.renishaw.com/additive.