Very high-speed scanner introduced

Munich, Germany - At the recent Laser Munich show, visitors were challenged by demonstrations of the LSE170A from Next Scan Technology, Evergem, Belgium. The opportunity to leverage throughput by high scanning speed and large area processing generated a number of inquiries for 2.5D applications such as micromachining, patterning, scribing, on-the-fly drilling, and marking. Most of these applications need a high-repetition accuracy, which demands very precise laser pulse timing at high scanning speeds.

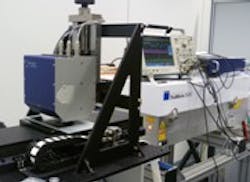

To solve the issue of timing jitter, Next Scan Technology developed SuperSync Technology for MOPA-architecture-based pulsed lasers, products that were among those ultrafast pulse lasers that dominated the production halls at the show. A bidirectional control between scanner and laser needs to be in place to guarantee the best spot positioning. The necessary engineering effort on this interface is supported by a selective group of laser manufacturers. Recently, the control interface with TRUMPF and their TruMicro system was successfully tested (see photo above).

High scan speeds on large areas challenge existing scan strategies on throughput. To explore the benefits of polygon scanning technology in the shortest period of time, Next Scan Technology has released the Process Development Kit (PDK). This kit saves companies' valuable time in integration and commissioning efforts. The PDK is a compact lab for laser material processing, set up and ready for demonstration in Next Scan’s demonstration center.