For the third time, experts in the field of micromachining met at the invitation of 3D-Micromac at ISL 2010, the International Symposium on Laser Micromachining (FIGURE 1).

In micromachining, short and especially ultra-short pulse lasers are on the way to replacing conventional processing methods. For ultra-short pulse lasers, there are hardly any restrictions regarding the materials to be processed thanks to cold ablation.

In cold ablation, the removal of material is essentially achieved only through the breaking of chemical bonds, so that the thermal influence is limited to a few micrometers and the corresponding deformation is minimal. However, in metal processing, the energy of the electron gas is partly transferred to the grid. Since removal occurs rather than the diffusion of energy in the surrounding area, hardly any problems occur due to melt splashes and distortion. Ultra-short pulse lasers are still not quite in widespread industrial due to the fact that their ablation rates are unfortunately still low.

The ablation threshold is in the range of 0.2 J/cm2 for metal to several J/cm2 for glass and ceramics. In order to increase the removal rate, one can use high pulse energies with a larger focus diameter to work larger areas. In transparent materials such as glass or polymers, the removal rate can be improved by using nonlinear effects such as multiphoton processes. Furthermore, the repetition rate can be increased. Here, rates from 100 kHz to a few megahertz are available, with research being conducted on rates exceeding 10 MHz.

While conventional fiber lasers have long been established in the industrial environment, femtosecond fiber lasers are still quite new on the market. Dr. Jens Limpert of the University of Jena works with an ultrafast fiber laser with an average power performance of close to 1 kW, peak powers in the GW range, and repetition rates from the kHz up to the MHz range. Nevertheless, there is still lot of development potential available here.

Instead of single pulses, another way to increase the ablation rate is to use so-called bursts. In doing so from a pulse train, for example of 50 MHz, pulses with a repetition rate of 500 kHz are picked out and amplified.

"Ablation behaves logarithmically in relation to the pulse energy. In this way, I can distribute the same total energy over several pulses and then with the sum of the pulses achieve a higher removal volume," says Dirk Müller from Lumera Laser. Proven as effective have been bursts of five to 10 pulses, and pulse intervals of about 20 ns have been proven. However, the quality of the removal strongly depends on the material to be processed.

Efficient production of microstructures

Well-established methods for micromachining are EDM (electrical discharge machining), micro-embossing, and lithography. EDM only works with electrically conductive materials and it is slow. Stamping dies are expensive to manufacture. Also, lithography requires high-precision masks, and the subsequent etching process is far from being environmentally friendly. The cold ablation works here with comparable accuracy and is also environmentally friendly and usually much more cost effective.

The stamping of the finest structures makes sheet metal easier to be processed and the sheet metal structures are made by embossing rollers. The Fraunhofer-ILT has obtained the best results with a picosecond laser operating at 100 W and a 3-MHz repetition rate.Thanks to cold ablation, ultrafast lasers can also be used for processing plastics. Almost all process equipment for the production of OLEDs is unique. And since the manufacturing process of organic photovoltaic cells and OLEDs is similar, engineers at the Fraunhofer-IMPS have developed the Gen2 pilot production line for OLEDs and OPVs. The OLED layer system is deposited by OVPD (organic vapor phase deposition) or VTE (vacuum thermal evaporation) onto a plastic film with an ITO (indium tin oxide) layer. Deploying lasers for structuring is optimal because they work fast and setup times can be neglected.

"The lithography-free process provides the same good quality as the lithography process, but is more flexible regarding the layout and less expensive," says Dr. Christian May from the Fraunhofer-IMPS.

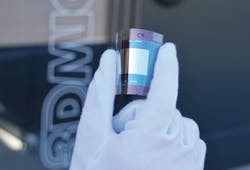

Work is carried out on the same problem at 3D-Micromac. A modular system has been developed where organic, flexible solar cells and OLEDs can be produced fully automated in a roll-to-roll process under normal environmental conditions (FIGURE 4).Another application in roll-to-roll laser micromachining with ultra short pulse lasers can be found in automotive glazing. Since the windows of vehicles are getting larger, the car gets increasingly hotter when the sun shines. However, the coating of the window creates a Faraday cage and dampens communication. To remedy this situation, the coating must be partly removed without interfering with "cosmetic" aspect.

"A picosecond laser can operate on the back of the film and the beam passes through the substrate without destroying it," reports Christian Scholz from 3D-Micromac. The project is currently in the emulation phase.

For industrial production, the removal rate is not a big problem compared to the possible scanning speeds. For efficient production, scanning speeds of about 200 m/s and above are needed. This is possible with phased-array deflectors, which achieve more than 500 m/s, but these systems are still under development and currently not available for industry.

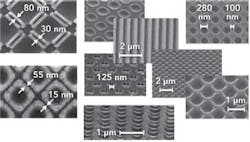

Another way to circumvent the problem of slowness is to work in parallel with several partial beams. The diffractive optics used for splitting the beam only manipulate the optical phase of the beam and have a very large transmission. These optics made of quartz glass can be produced cost-effectively, thanks to cold ablation, also by ultra-short pulse laser.

Another way to produce periodic nanostructures is to use interference. This means that all materials can be processed in this way involving superimposing several partial beams of an ultra-short pulse laser with a short wavelength and thus producing an interference pattern with a high resolution (FIGURE 5)."The method functions reliably, and we are currently up-scaling it to meet industrial requirements," says Dr. Peter Simon of Laser-Laboratorium Göttingen e.V.

Cutting by means of laser ablation

Cutting of metal foils with conventional lasers means that a gas nozzle must also be used to blow out the melt, and a special contour-matching cutting tool is necessary. Apart from the tooling costs, the flow of gas for the molten metal can distort the foil; the relatively high energy input bends the foil; and ridges can form on the cutting edge. The laser beam of a short pulse laser travels several times over the cutting path, thereby gradually working through the material. It suffices to fix the foil by suction onto on a perforated plate.

"The only limits are a smaller work area, and a lower positioning accuracy, which depends on the focus position and the calibration of the scanner," says Daniel Hubert from Günter-Köhler-Institut Jena. Above a film thickness of 100 microns, the process will become uneconomical because of the long processing time.

Ultra-short pulse lasers have a small narrow focus for cutting widths of less than 20 microns. The cutting of manufacturing chips with the lasers allow a much higher packaging density and makes it possible to get approximately twice as many chips per wafer as by conventional techniques. The picosecond laser also brings profit in the cutting of stents. It saves on costly material and finishing compared to conventional production and causes less waste. Cutting Si wafers has also been successfully performed using the ultra-short pulse laser, making thinner wafers of less weight possible.

With these short and ultra-short pulse lasers, there is practically no restriction on the materials used, and ablation takes place with the highest precision. Thus, the possible applications are correspondingly broadly diversified, from the possibility of working on biological tissue to the processing of material stacks and composites, here especially with CFRP (carbon fiber reinforced plastic), a material not easy to handle. To present further progress in development, 3D-Micromac will once again extend an invitation to another meeting in 2012.

Barbara Stumpp | Freelance Science Writer

Barbara Stumpp is a freelance science writer based in Germany.