Russian gum manufacturer chooses laser coders

Novogrod, Russia – Gum manufacturer Dirol, part of the Cadbury Corp., has installed more than 40 Domino coders and is now is enjoying significantly lower maintenance and consumable costs on its production lines.

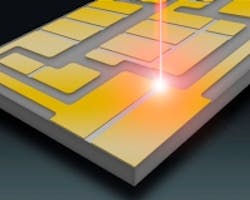

"We experienced significant reliability and maintenance issues with our previous coding equipment and as the running costs were also very high, we decided to investigate different coding options from other suppliers,” says a Dirol spokesman. “Laser coding seemed like a suitable alternative, so we looked at various systems that could potentially meet our requirement to reproduce codes on primary foil packaging as well as multi-pack cartons. We ran benchmarking trials and undertook detailed examination of code samples, based on which Domino’s D-Series| coders stood out as the best choice for Dirol."

Ten Domino laser systems – five 30 W models for primary coding and five 10 W models for coding alphanumeric variable data – a production line code, manufacturing, and expiry date – onto colored foil at around 100 packs/minute. They have been getting sharp and clear marking from day one, with much less need for maintenance, thereby saving a considerable amount of money on consumables with a massive reduction in downtime, the spokesman said.

The laser coders have now been integrated onto all Dirol’s older packaging lines, where several primary foil lines feed into a single multi-pack carton packer. For this, the D-Series lasers were fitted with an axial beam output to accommodate intermittent coding.