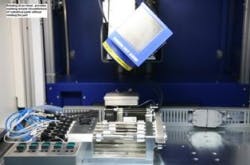

Champlin, Minn. – The Rapido, a large work envelope, high speed 3D laser processing system used in a large variety of applications including laser cutting automotive hot formed steel components and appliance manufacturing, is now being manufactured by Prima Power Laserdyne LLC in its facility here.

Previously manufactured and delivered worldwide by Prima Industrie, S.p.A., the parent company, in its Torino, Italy plant, Rapido laser systems will now be assembled, tested, and supported by US workers in Champlin.

This system is an established and leading-edge manufacturing technology system used by many US automotive and appliance manufacturers. "Rapido systems give these manufacturers the needed automation and production efficiencies required to be successful in the marketplace," said Terry L. VanderWert, president of Prima Power Laserdyne. "They do this by operating non-stop, automatically handling and cutting very large quantities of parts in a 24/7 manufacturing environment."

These systems laser cut and trim a typical automotive B-pillar body panel in less than 50 seconds, producing very high quality cut edges that are free from oxide and that are weld and paint ready. No costly added operations are needed to the cut edges in preparation for welding, assembly, and painting of the panels.

For more information, e-mail [email protected]