JP Sercel Associates (JPSA), Manchester, NH, has released a new system for scribing and dicing metal layers and alloys used in LED manufacturing.

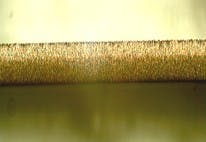

The IX-6100-MD can scribe and dice a variety of metal layers (Mo, Cu, Ni, Au, Ag, Zn) and their alloys used in LED manufacturing. A proprietary beam delivery system enables independent 2D adjustment of the laser beam shape, to optimize the laser energy used for cutting and achieve a minimal kerf width (20 μm) while minimizing the heat-affected zone. JPSA's proprietary vision and scribe placement technology reduces die street size and enables more LED die per wafer. The system can be equipped with the company's Integrated Automation Platform (IAP) for automated wafer handling in production environments.

JPSA says it will ship several of the new IX-6100-MD systems in 3Q12 to an unidentified leading LED manufacturer in Asia, to be utilized for singulating high-power LED devices in which the metal substrate assists in LED heat dissipation.

About the Author

James Montgomery

Associate Editor

James manages editorial production for news (online and print) and newsletters, as well as the magazines' new product sections. Jim has 13 years’ experience in producing Web sites and e-mail newsletters in various technology markets for CNet, ZDNet, Digital City Boston/AOL, and KM World.