Laser welding: Is your application report an effective sales tool?

Laser application engineers are challenged by an abundance of new and uniquely different laser welding applications and opportunities. Product manufacturers in the medical, aerospace, electronics, solar, and micro-manufacturing industries continue to incorporate new materials and product designs that require innovative laser welding approaches. Moreover, many of these customers demand higher levels of process validation and documentation before investing in an expensive laser system. As a result, the laser application engineering function, facility, and weld process documentation play a significant role in winning their business.

The first step in gaining a prospective customer's trust, confidence, and ultimately their business is to create a detailed laser welding application plan. This plan should provide the application engineer with the full scope of work and written guidelines for achieving a reliable, repeatable laser welding process solution. The plan should also foster creative ideas to optimize the weld process and return on investment.

The application report

The application report is the key document used to communicate the laser welding process and results to the customer. This document should not be a "pass" or "fail" feasibility test report card. Rather, the application report should provide detailed information regarding the laser and beam delivery equipment, laser settings, motion, vision, tooling, cover gas, and other data necessary to duplicate the laser welding process with the same results.

A laser welding application report will typically include cross section photography and applicable test data to validate the weld process and fully qualify the laser welding approach. A separate application report is desirable for each different set of laser settings or other variables that meet or exceed the weld specifications. Collectively, these reports confirm the laser welding process window. In addition to the customer contact information, a comprehensive application report should include the following information.

Weld specifications and deliverables—The materials being joined, weld specifications, deliverables, and the customer's overall expectations should be summarized in the application report. Weld specifications should include drawings of the parts being welded, the type of weld joint, positional tolerances, laser weld penetration, weld nugget diameter, mechanical strength, HAZ concerns, cycle time goals, and cosmetic appearance. Cover gas use shall be documented including the type of gas, flow rate, and on-axis or off-axis gas delivery.

The customer may specify the number of qualifying samples to be delivered including the quantity of samples to be cross-sectioned, photographed, and tested. All mechanical, electrical, metallurgical and/or hermeticity tests required to qualify the weld process should be disclosed together with the test procedures and equipment needed to complete the tests.

Pre-weld inspection and cleaning—The application engineer should inspect all incoming samples and materials to confirm they are the correct material or part, have no visible damage, and otherwise are suitable for the process development work. It is recommended the application engineer properly clean the materials and tooling for laser welding. The materials should be stored in a clean environment and handled in such a manner as not to introduce fingerprints or other potential contamination.

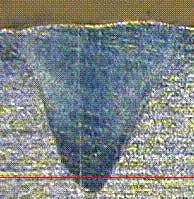

Post-weld inspection—Post weld inspection equipment and validation procedures should be described in the application report. Typical post-weld inspection and process validation may include visual inspection at 40x to100x magnification. Some samples will typically require cross sectioning and digital photography to show weld penetration, inclusions, micro-cracks, splatter, undercutting, HAZ, and nugget diameter. If available, the customer should provide cross-sectioned photographs and samples of acceptable welds (see Figures 1, 2, and 3).Laser/CCTV alignment and beam waist position—A brief description of the focusing procedure should be documented. The sharpest focus "sweet spot" of the beam waist shall be co-incidental with the sharpest CCTV image. Steps shall be taken to minimize the subjectivity from one operator to another due to differences in vision characteristics. The report shall indicate where the "sweet spot" was focused (ie: 0.010 in below the surface).

Pulse shaping—Pulse shaping may be required for optimizing the laser weld process. A sketch of the pulse shaping profile should be included in the application report indicating the average power, pulse energy, pulse width, and peak power in each segment. A copy of the waveform should also be included if available.

Power ramping—The application engineer should determine if there is a benefit to power ramping, such as suppressing last pulse micro-cracks. If power ramping is employed, the power ramping schedule should be documented in the application report. Digital photographs of the weld surface should be included showing the power ramp results (see Figure 4).IP and non-disclosure agreement—Laser suppliers and their application engineering personnel must be diligent in preserving intellectual property and complying with any non-disclosure agreements. Samples, materials, tooling, drawings, photographs, specifications, software programs, files, and other items provided by the customer shall be returned upon request.

Summary

Medical, aerospace, electronics, solar and micro-manufacturing industries continue to utilize advanced metals and more complex product designs that require creative laser welding approaches in the manufacturing process. The depth and detail of the information provided in the application report is subject to debate among competitive suppliers. However, many prospective customers require a detailed application report and other documentation to validate the weld process before investing in an expensive laser system. While this can be a time consuming effort, the first laser vendor to deliver qualifying samples and well-documented process validation usually enjoys a competitive advantage.

Craig Marley | Director of Business Development, Laser & Systems Division at Unitek Miyachi Corporation

Craig Marley is director of business development for the Laser & Systems Division of Unitek Miyachi Corporation (Monrovia, CA).