Additive manufacturing standardization in works for the oil, gas, and maritime industry

In January 2018, 11 companies started two Joint Innovation Projects (JIPs) to develop a guideline and accompanying economic model for the additive manufacturing of qualified, functional metal (spare) parts for the oil, gas, and maritime industries.

The group, which has grown to 16 partners, includes Equinor, BP, Total, Kongsberg, OCAS, Ivaldi Group, TechnipFMC, Siemens, Voestalpine, Vallourec, Aidro, SLM Solutions, Additive Industries, Quintus, HIPtec, and the Advanced Forming Research Centre of the University of Strathclyde. The partners are working on two coherent and seamlessly aligned programs:

- A guideline towards certified parts, managed by DNV-GL

- A toolbox for selection, supply chain setup, and economic viability, managed by Berenschot

The aligned setup of the two programs secures maximum cross-fertilization. SLM Solutions supports the projects by providing its technical expertise in additive manufacturing, specifically the implementation of selective laser melting (SLM) technology.

The practical guideline, which will be made available by June 2019, will provide a framework to ensure that metal parts produced via SLM technology and wire arc additive manufacturing are according to oil, gas, and maritime industry specifications. This means that parts meet stated quality and are manufactured in a safe and repeatable manner.

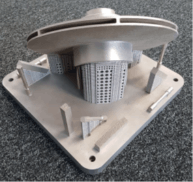

Up to five pilot parts will be produced for the project to ensure all necessary steps for repeatable, quality production. One example of these parts is a pump impeller that SLM Solutions manufactures for Equinor on the SLM 280 machine. The partners will do a final test of the applicability of this guideline during the production of these pilot parts, focusing on the practical use of the guideline in production and quality of the parts achieved. The takeaways from these case studies will be implemented in the final version of the guideline.

Also to be released in June 2019 is a comprehensive and fully functional business tool that will help determine the bottom-line impact of 3D printing spare parts compared to traditional manufacturing methods. This model will be tested during the Q2 part production process. In conjunction with this return-on-investment model, a database of parts will be compiled to showcase the applicability of additive manufacturing for spare parts in oil, gas, and maritime applications.

For more information, please visitslm-solutions.com.