Project to develop laser microtexturing system for metallic and plastic surfaces

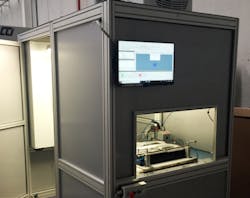

The Technological Centre for Plastics (Andaltec; Martos, Spain) has launched a R&D project in which the center will develop a laser microtexturing system that will yield plastic parts with aesthetic properties and advanced functions. Fully developed within the center, the project intends to validate a laser device to microtexture plastic and metallic surfaces, with a final goal of achieving the technological capability to modify the superficial state of plastic parts or the metallic matrices molding them.

The project's purpose is providing the plastic part with special properties, such as allowing light to go through, in a selective and uniform way, machining of mold inserts with zero radius, or providing the desired area with anticondensation or hydrophobic properties. This technique can also be used for academic or research purposes, in experiments searching for future applications still to be identified.

Thanks to this project, Andaltec will be able to make this Advanced Technological Service available for companies, so that they can in turn offer this technology to their customers, boosting their productivity. In the future, the technological center intends companies to continue exploiting results, manufacturing and marketing machines serially, always counting with Andaltec's consulting services.

This project is inscribed within Andaltec's specializing scheme on industrial laser processes, as a consequence of the center's participation in important international R&D projects in this area. Andaltec has developed in recent years technological capabilities focused on techniques such as laser cutting, welding and microstructuring, especially for the automotive and food packaging sectors.

Andaltec already counts with a specialized laser area, working on cutting, welding, and joining, even between materials with different fusion point and nature, such as joining plastic and metal materials. Andaltec has acquired these technological competences through its participation in European projects such as PMJoin, in which they have developed an innovative system to join plastic and metal using laser techniques.

Another European project in which Andaltec participates is Essial, which focuses on the development of new industrial processes to join metallic structures with a laser. The consortium in charge of this project, in progress until 2021 funded by the Horizon 2020 European scheme, is currently researching advanced manufacturing processes to enhance the performance and functionality of magnetic circuits present in power converters. The same team at Andaltec developed equipment for thermoconformed part cutting by means of laser technology for a company in Jaén, Spain. This technique allows cutting complex parts quickly and accurately, leaving a nonaggressive edge on the part. This program receives funding from Jaén’s Provincial Government, thanks to the grants directed to the technological centers in the province to improve the competitiveness of economic sectors and employment rates, all of that within the General Employment Programme for the Province of Jaén 2018.

For more information, please visit andaltec.org.