East Granby, Conn. – Joining Technologies is adding a new laser cladding work cell to its laser additive manufacturing division and will open an additional production facility next month to house the unit along with other equipment related to the laser additive process. The standalone 10,000 square foot multipurpose industrial flex building is located at 17 Kripes Road, East Granby, less than a mile from Joining Technologies’ headquarters.

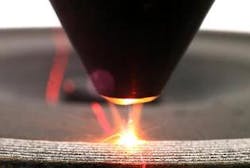

The new facility will be dedicated to laser additive (laser cladding) manufacturing, a process used to improve the mechanical and corrosion resistance properties of a wide range of parts. With drive through and dock height access, the building will have the capacity to lift and manipulate parts up to 3.5 tons. It will contain laser cladding equipment capable of processing parts up to 40 feet long. The facility’s location near Bradley International Airport and major highways makes it easily accessible to customers.

“We are excited to open this new facility in response to our growth in this area,” said Dave Hudson, company president. “The new wholly-owned division of Joining Technologies is expected to add several jobs over the next year.”

In addition to the state-of-the-art manufacturing facility, the building will also be the future home of a laser additive technology institute, North America’s first and only center of excellence for laser additive manufacturing.

The joint venture with a leading European-based authority on laser additive manufacturing processes will focus on laser additive processes for original equipment manufacturers (OEMs) in the aerospace, power generation, marine engine, and other high value industries. Research and development will be conducted to produce methods and parameters to repair high value parts and put them back into service or create new parts using laser additive processes.

Joining Technologies is an innovator in precision fusion processes, including laser and electron beam welding applications, laser additive manufacturing, and weld system design and integration. The company continues to develop economical solutions for joining metal components primarily in the medical device, sensors, aerospace, military, energy, and firearms industries.

For more information, email [email protected]