Lasit USA introduces CompactMark 2010 laser marking system for medical industry

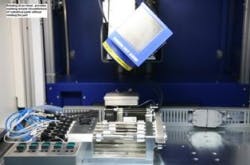

Lasit USA, Franklin, Mass., has introduced its newest versatile laser marking system for metals, plastics, and glass for the medical industry. The CompactMark 2010 with optional B & W and color vision system for location and positioning of marks and parts has enhanced features for marking medical devices, body implants, and all size screws and parts made of stainless steel, aluminum, titanium and plastics.

The Lasit system has up to eight motors in one machine for marking cylindrical parts, measurement rings, tapered probes, endoscopic rods, plastic handles, trays of varying parts, and inside and ends of trays for surgical instruments. Up to 32 characters can be marked and read with vision on a screw as small as an eyeglass screw.

An optional rotating scan head or gantry configuration with motorized XYZ allows for marking around curved surfaces and cylindrical parts, with different heights and geometries as well as the ends of each part without moving any of the parts. Hot dog rollers allow for rotating multiple parts at one time.

There are three standard sizes from 690 x 400 mm up to 1290 x 400 mm and larger custom tables with holes and threads to anchor fixtures securely. Rotary dial tables are also available up to 48 inches in diameter to mark while loading/unloading. One machine is designed to mark hundreds of different parts all within one enclosure.

FlyCad and FlyControl Software is designed to provide serialization, bar codes, UID codes, 2D Matrix, logos, radial text, and more. Lasit offers testing in laser labs and will provide reports with samples to evaluate the quality and cycle times.