Tony Hoult, an editorial advisor to Industrial Laser Solutions on industrial fiber laser applications, recently had the opportunity to test the latest fiber laser technology in IPG Photonics' laser micro-processing laboratory in Santa Clara, Calif. Hoult is the general manager, West Coast operations, at IPG, and he has a long history as a laser material processing specialist in both industry and academia. Hoult has been applying fiber lasers to a variety of industrial applications, where he can compare the processing advantages of these lasers. He is impressed by the early results obtained from a new quasi-CW fiber laser that his company has developed. At the recent ICALEO conference, Editor-in-Chief David Belforte asked him to report on his findings.

Santa Clara, Calif. – Nobody in the laser industry can have failed to notice the recent trend toward fiber lasers for material processing. Having been involved with fiber laser applications fairly early on in their development, I would like to share some brief comments on fiber lasers and on a new variant, the quasi continuous wave (QCW) fiber laser.

A short history: laser marking was the first major commercial success for fiber lasers followed closely by higher power laser cutting and welding applications; many others have followed. The position now is that almost all industrial laser applications have now been attempted with fiber lasers, usually with a good degree of success. Obviously, it takes many years to penetrate all of the different application areas, and none of the incumbents relinquish their market share lightly. As a user of these smaller, more efficient QCW lasers, I have learned that two of the their most important benefits are:

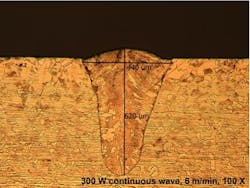

1. They are easier to use. Laser stability is good; if a process is not repeatable, it is not usually the fault of the fiber laser. Whatever the type of fiber laser, the stability of the laser is directly reflected in the quality of the result. In the case of laser welding, unless there is a serious problem with tooling, material quality, surface finish or any other process variable, weld quality is good with fiber lasers. Figure 1 shows a typical cross section of a very high speed continuous wave weld; this weld was made with no cover gas and with no surface preparation.

2. Fiber lasers need almost zero maintenance. The laser really has now become a black box. In a well set up process, no operator intervention is required. This means that laser specialists are not necessarily required for 24/7 operation.

Figure 1. Continuous wave fiber laser weld, no gas cover.

QCW laser

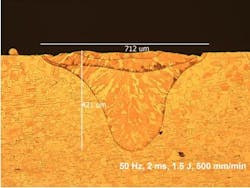

I believe that the quasi continuous wave (QCW) laser from IPG Photonics is an important new development. This laser has a range of pulse lengths from 0.2-10 ms and a peak power of 1500 W. An almost Gaussian beam with an M2 of < 1.1 from the single mode active fiber means that the brightness is probably in excess of anything else available in this format. This alone makes it a serious competitor in the home territory of the flashlamp pumped Nd:YAG laser, but with optional 50, 100, or 200 µm delivery fibers and a range of collimator focal lengths, an enormous range of spot sizes are available at the workpiece. An example of how the weld shape resembles that of a conventional flashlamp-pumped YAG laser and differs from that made by a continuous wave laser (Figure 1) is shown in Figure 2.

Figure 2. Quasi continuous wave (QCW) spot weld.

The current production standard is a 150 W laser with a maximum of 15 J pulse energy, more than enough for almost all welding and drilling applications, although for laser cutting, high pulse energy is not usually required. This laser can be run at 250 W continuous wave power. 400 W average power / 4000 W peak power and 600 W average power / 6000 W peak power versions are also available.

It has already been shown in IPG's application labs that this laser can match the performance of flashlamp-pumped lasers in any application and can outperform them in most. The laser has now been christened the 10 X laser because it reportedly has 10 X the lifetime of a diode-pumped solid state laser (at least 20 X the lifetime of a flash lamp pumped laser), 10 X the efficiency of a Nd:YAG laser and 10 X less floor space than a conventional flashlamp pumped laser.

Having used this laser for some weeks now and having evaluated it for a number of applications, I believe that this laser has the capacity to replace flashlamp-pumped Nd:YAG laser technology.

Contact Tony Hoult at [email protected]