Laser Components introduces AR coatings for optical fibers

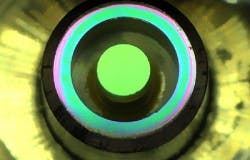

Laser Components, Hudson, N.H., has introduced anti-reflection coatings for use when high power has to be transmitted across optical fibers using a laser. These coatings significantly reduce coupling losses. This high power advantage has a particularly positive effect in medical technology and material processing.

Laser Components offers both assembled cables, including coated fibers, and job coatings on fibers supplied by the customer. The company can process all types of fibers – from fused silica fibers (SM and MM) to sapphire fibers. The company says it is important that all materials used, for example, in buffers, be suitable for vacuum environments.

The following AR coatings are available on a standard basis for optical fibers:

--Single ARs: AR coating for one wavelength (e.g. 808 nm)

--Dual ARs: AR coating for two wavelengths (e.g. 808 and 980 nm)

--Broadband ARs: AR coating for a wide wavelength range (e.g. 460-700 nm)

Customer-specific coatings are also available

Laser Components specializes in the development, manufacture, and sale of components and services for the laser and opto-electronics industries. With sales offices in four different countries, the company has served its customers since 1982. In-house production at six locations in Germany, Canada, and the US began in 1986. Currently, the family-run business employs more than 120 people worldwide.