Aachen, Germany - The Fraunhofer Institute for Laser Technology (ILT) will present a laser welding innovation, TransTWIST, at an upcoming trade fair. TransTWIST welds together two transparent joining parts without having to add any laser beam energy absorbers.

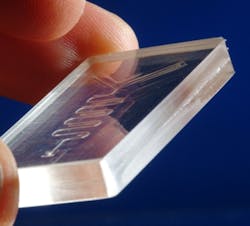

Microfluidics component made of plastic, welded using TransTWIST. Photo courtesy: Fraunhofer ILT.

At this year’s K 2010 international plastics trade show in Düsseldorf (October 27 to November 3), the Fraunhofer ILT is presenting the TransTWIST laser-based plastics welding machine. In live demonstrations, the researchers will show how two transparent plastic parts can be lap-welded using laser radiation. In conventional laser welding, a suitable radiation absorber is normally applied to the underlying joining partner. This is time consuming and costly. Furthermore, the appearance of the component or weld is affected by the color of the radiation absorber.

In order to weld transparent plastics without any seam marks, the researchers at the Fraunhofer ILT have developed a laser machine for welding plastics. In a lap joint configuration, transparent polymers are welded without the addition of infrared absorbers. This eliminates the need for elaborate pretreatment, saving process time and costs, and represents a breakthrough in plastics laser welding.

TransTWIST produces high-quality welds that meet all the usual requirements in terms of being free from weld marks and restricting the zone influenced by heat. TransTWIST shows a great potential for use in the bio-biomedical field, especially in microfluidics, packaging, and design applications.

For more information: contact [email protected]