Collaboration to offer 3D printing technology for the molding industry

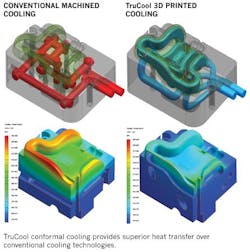

DME (Cincinnati, OH) has partnered with Linear AMS (Livonia, MI) to offer metal 3D-printed conformal cooling products to help improve productivity in the molding industry. DME's TruCool products, which are designed to help moldmakers and molders with their mold cooling, use a 3D printing (also known as additive manufacturing) process to produce highly complex cavities, cores, and components with conformal cooling channels. The process achieves shapes, paths, and channel geometries impossible to obtain with conventional tooling.

"The conformal cooling solution places cooling channels at the optimal distance from the mold surface, consistently following the geometric shape of any mold insert for any customer part, allowing the mold to maintain a targeted, consistent temperature that allows for complete thermal control with cooling times reduced up to 100%," explains David Baucus, product manager at DME.

The DME/Linear AMS process uses advanced direct-metal laser melting (DMLM) technology, which is extremely dense and stronger when compared to direct-metal laser sintering. This allows for lighter-weight solutions with improved performance characteristics to create complex shapes and improved reliability.

"Our real-world, in-field results show a significantly reduced total cycle time—between 15% and 60%, depending on part complexity, shortening the time needed to run the part and improving part quality," says Peter Smith, president at DME. "That's a significant cost savings every molder would be interested in. Likewise, OEM/product designers will benefit from the technology, as it broadens the scope of part design, allowing for advancements in plastic part production and application use."

For more information, please visit www.dme.net and www.linearams.com.