New Technology Simplifies 3D Free-form Laser Marking

Lasers can mark most materials, in a high speed, noncontact process which is also flexible, meaning that customized marks, such as sequential serial numbers or complex graphics, are easily produced. And as the capabilities of laser marking improve, the use of the technology has expanded from producing merely utilitarian marks (e.g., UDI marks on medical devices) to decorative design or features (e.g., plastic automobile parts) that provide a perceived added value to the product. However, marking on non-flat surfaces has remained a complex and higher cost process, often requiring robotics to move the part and/or beam delivery optics. In the simplest example, writing a straight line on a curved surface at non-normal incidence will otherwise produce a curved line on the part.

Coherent has developed a new system that simplifies 3D marking and reduces the cost of creating even complex marks, because it involves neither moving the optical system nor the part itself.

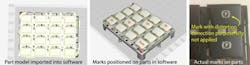

Functionally, there are two main elements to this system. The first is a fast focus module placed within the optics. This allows rapid focal length adjustment. Depending upon the particulars of the laser and scan system, a total range of up to ±130 mm from the nominal focal distance can be accommodated. The second element of the system is a sophisticated yet easy-to-use smart software package that imports a 3D CAD drawing of the workpiece and the desired mark. This software automatically determines the combination of focus module and galvanometer mirror movements required to produce the mark.

By using a 3D CAD drawing of the part and calculating the effects of projecting the laser from a fixed point, the system can produce non-distorted marks on virtually any surface shape or angle.

The figure shows how well this works in practice. Writing a circular mark on an angled surface, the smart software corrects for the inherent distortion that would normally occur.