Digitalization enables gains in laser remote welding

While most scanner-based laser welding of automotive applications such as hang-on parts, seat structures, or body-in-white are well understood and implemented by most OEMs and their suppliers, strong market growth is observed for all kinds of components related to electric vehicles and lightweight structures. This article discusses in its first section the possibilities to improve existing laser remote applications, especially for welding of hang-on parts, by using optical coherence tomography (OCT) technology. The second section introduces a way to improve the on-the-fly welding of 2D structures such as batteries for vehicles. Finally, the third section reviews the tasks of a laser welding instrument for the welding of hairpins used to join copper wires in stators of electric engines.

The OCT technology was introduced as a tool to gain information from the laser welding process. The OCT sensor itself is an optical setup that allows performing of point-distance measurements at high sample rates and submicrometer resolution by using its own light source. Distance measurements can therefore be performed in the closest vicinity to the melt pool or even in the keyhole itself, allowing measurement of its depth.

The OCT measuring light can be deflected by means of a 2D scanner to move the measuring spot along defined scan patterns, resulting in topographical maps. The gained height information can be used for a variety of applications, though in the context of laser welding, these are primarily pre-process edge finding and post-process seam analysis. Traditionally, these tasks are performed by using laser triangulation sensors that are limited to one welding direction and only suitable for fixed welding optics or very limited scan field sizes. By mounting a 2D scanner on any kind of welding optics, the coaxial OCT measuring beam can perform a variety of tasks.

On-the-fly welding

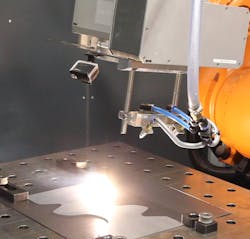

The OCT implementation as developed by Blackbird Robotersysteme (Garching, Germany) aims to augment the on-the-fly capacities of a 3D scanner mounted on a six-axis robot (FIGURE 1). On-the-fly welding, as it is currently being used, maximizes the processing speed and the duty cycle, but lacks performant seam tracking capacities. The adoption of fillet welds instead of overlap welds is a well-known evolution to reduce the weight of parts and to weld aluminum. By using OCT, the edge of fillet welds is detected and the laser beam accurately steered along the edge.

Fillet welds may suffer from gaps between the sheets caused by thermal distortions, insufficient clamping, or large tolerances. A high-frequency beam oscillation adapting itself to the size of the gap was demonstrated to be a convenient approach to cope with this issue. Fundamental weld parameters are the oscillation amplitude, the power distribution, and the relative offset to the top workpiece’s edge. All of these parameters are adjusted in real time by the Blackbird system in function of the measured gap between the two parts.

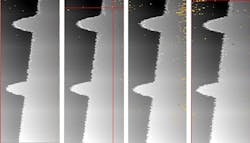

The high-frequent oscillation, performed by the main galvanometer mirrors of the 3D scanner to allow the laser beam oscillation, also deflects the OCT measuring beam. This OCT solution can cope with oscillations up to 1 kHz without reducing the quality of the workpiece’s topography scan. FIGURE 2 depicts four OCT scans performed through the intelliWELD PR 3D scanner at different oscillation frequencies. No relevant differences can be observed in these raw data sets, proving the usability of OCT for welds with laser beam oscillation.The combination of omnidirectional seam tracking, simultaneous OCT scanning, and beam oscillation gap bridging capacities, together with an on-the-fly capable 3D scanner, is a high-performing tool that allows for a wide field of applications.

Battery welding

The rise of electric mobility comes with new components for vehicles, most of them related to the energy storage and powertrain. A common application is the welding of battery cases and the connection of battery poles to the busbar. As the busbar is mounted to a full stack of batteries, the dimensions of the workpiece exceed the scan volume, requiring moving the scanner or the workpiece itself. To date, most implementations are based on static welding processes. While displacing the scanner from one group of welds to another, precious welding time is lost. Further, the laser beam hits the workpiece under different angles, leading to slight variations in the appearance of seam cross-sections. Robot-based on-the-fly welding can improve the situation, but comes with the cost of floor space and investments required for the robot.

As most battery stacks are planar 2D structures, the scanner can be moved by means of one or two linear stages. Blackbird implemented an on-the-fly capability for such handling devices, named real-time extension (RTX), to enable feeding up to two encoder signals into the scanner controller. The actual position of the linear stage is used to control the beam deflection by the scanner, which allows welding of workpieces with sizes up to several meters in one pass. Ideally, the scanner is moved at a velocity high enough to reduce the laser-off time to a minimum. Lab tests have proven that laser-on times of more than 99% can be achieved for welding the busbar to the batteries.

Additionally, the encoder data is also fed into the RoboSyncUnit software and provides a preview of the scanner’s trajectory. In a second step, the precise moment of welding can be manually adjusted to either reduce laser-off times or optimize the angle of incidence of the laser beam for every single seam. In a third step, the overall laser-off time can be reduced by increasing the axis’ velocity.

RTX has capability to improve 2D welding applications, especially aiming for battery welding applications. The combination of linear stages and scanner-based welding maximizes the throughput of the machine. One of the first integrations of the RTX will be able to process more than 100,000 units in a machine built by Strama-MPS (Straubing, Germany).

Hairpin welding

Alongside the power storage, the powertrain components will see a huge and fast development. The welding of copper wires for stators from electric drives, also known as hairpins, has become a widely used laser welding application in recent years. A key to success is not only the right choice of process parameters, but also the implementation of machine vision techniques to detect the wires, perform and optimize the welding process, and later to perform a quality assessment of the weld.

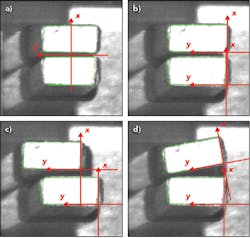

The newly released ScaVis (Scanner Vision) extends the capacities of a 2D/3D scanner by adding a coaxial camera with its own illumination modules (FIGURE 3). Any image processing tasks required can be performed by action elements integrated into the welding workflow of the user software. In the case of most hairpin applications, the localization of the wires is required prior to enabling the laser.Conclusion

The three applications discussed, namely remote welding of hang-on parts with seam tracking, on-the-fly welding with linear stages, and machine vision-assisted welding of hairpins, benefit from an in-depth communication between sensors, the scanner, actuators, and control units. Data processing and data sharing among all devices thus signify important elements to increase the quality and productivity, followed by lower costs per part. This evolution is crucial to cope with competing joining technologies and rising labor costs. The digitalization became a mainstay of the remote laser welding process.

Thibault Bautze-Scherff | Sales Manager & Member of the Executive Board, Blackbird Robotersysteme

Thibault Bautze-Scherff is sales manager and a member of the Executive Board at Blackbird Robotersysteme (Garching, Germany).