Laser replaces conventional industrial cleaning methods

LASER Technology is capable of cleaning or stripping of all types of metals and sensitive surfaces

JULIEN DECLOUX

Laser cleaning operations play a key role in the industrial world. With laser technology, cleaning possibilities are numerous: cleaning and surface preparation of a product (before shipment, before welding, and before painting), recycling of waste products, and cleaning of machines (cleaning, descaling, deoxidation, and degreasing). One of the main problems that industrial companies must face is the maintenance of tooling and, in particular, the cleaning of molds.

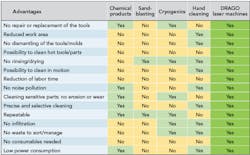

Currently, there are many conventional cleaning methods such as sandblasting, cryogenics, beadblasting, chemicals, and manual cleaning. However, they pose a lot of problems—damages to the material and treated products, overproduction of waste, shutdown of the production line, regulatory constraints, and muscular and skeletal disorders, among others.

Laser cleaning advantages

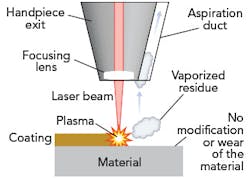

Laser cleaning means focusing a very strong energy in a beam of light to remove, by several effects (thermal, photochemical, ultrafast, and thermomechanical), a coating of varying thickness on any type of material.

Compared to conventional technologies, benefits of laser cleaning include precision, quality, profitability, productivity, and eco-responsibility (FIGURE 1). Laser cleaning is a contactless and noninvasive technology, and is the only solution that allows the cleaning of a precise surface with a more-or-less deep stripping impact. Instead of roughly spraying consumables as abrasive or sand, lasers enable a user to choose a precise area to be cleaned (FIGURE 2).On the safety side, laser solutions also offer benefits. The only personal protection needed is laser protective glasses, which are mandatory for the operator and any people near the laser stripping operation (the easier way is to confine the area with protective panels). There is no need for a special suit, gloves, or other equipment that may constrain the operator.

This photonic process does not require any consumables, therefore eliminating waste to sort or manage. The only waste recovered is the coating itself, which has been eliminated, and it represents small amounts of particles and sometimes smoke, depending on the type of coating. This is why suction systems are provided with laser stripping machines.

Cost of laser technologies

The cost of a laser system is in the range of $60,000 to $170,000, depending on the implementation—type of laser and power, type of automation, type of integration (on-line or off-line), and special constraints.

Then, add in the cost of operation and maintenance—considering the life of a laser source, the stripping hour cost is about $6/hour, depending on the technology and the laser power required. The filters inside the machines cost less than $560/year, and electrical consumption is <5 kW.

Depending on the nature and the thickness of the layer that needs to be removed, the rate can range from 1 to 10 m2/hour. Technology suitable for stripping thick layers can remove several tens of cubic decimeters per hour.

Application examples

Laser cleaning machines have uses in the automotive industry—for example, they are used to remove gum from tire molds or to remove release agent from plastic part molds. The laser focuses its energy only on the coating to be stripped and does not damage or wear the mold structure, so users no longer need to spend money on changing used molds.

The same is true for painted parts, where there are sometimes several millimeters of paint to remove because maintenance is done only punctually during the year, as it is necessary to stop the production line. With laser machines, cleaning can be done directly on the production line more regularly, which avoids a considerable loss of money.

Examples of laser cleaning applications include:

- Paint stripping

- Release agent removal

- Rust removal on metal

- Oil and grease removal

- Pre- and post-welding treatment

- Painting swing stripping

- Tire mold cleaning

- Tool and machine maintenance

- Bottle degreasing

- Surface preparation

Laser types

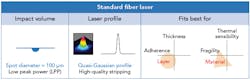

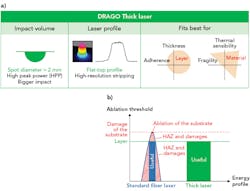

The fiber laser, mainly used until now in the industrial world, delivers quasi-Gaussian impulsions (M² <3) with low peak power (<10 kW) and a very high pulse rate (≈100 kHz). Due to its specifications, the heat input can be important and generate heat-affected zone (HAZ). The standard fiber laser turns out to be relevant to clean all kinds of non-fragile and conductive materials, including steel, aluminum, cast iron, and stainless steel. For good stripping, the laser spot must be microscopic to reach sufficient fluences. This makes it a good candidate for thin and nonadherent coating layers (FIGURE 3).To reach the materials and the coatings that the fiber laser cannot manage, Silltec (Saclay, France) has developed a new generation of laser that achieves the highest peak power (HPP) on the market (FIGURE 4a). To avoid heating of the materials, the average power has been reduced to allow time for the heat to dissipate between two laser impulsions. To avoid HAZ, a flat-top profile is produced, allowing cleaning or stripping of all types of metals and sensitive surfaces such as glass, composite, wood, or stone.

The HPP of the DRAGO Thick laser technology allows for a large laser spot for a bigger volume impact. This laser delivers top hat impulses with high peak power (>8 MW) at relatively low pulse rates (≈ 1 kHz). Due to its high peak power, it can eliminate thick and adherent coating layers.

Furthermore, this laser also allows a very high fluence in a reduced spot to cause a detachment by mechanical shock. This process is useful to eliminate very adherent coating layers. FIGURE 4b demonstrates that the DRAGO Thick laser better manages thresholds.This technology allows high quality because of its high selectivity. With a flat-top profile, there is improved differentiation between the substrate and the coating layer thresholds. This means that beyond the threshold, there is no energy transmitted to the substrate and therefore no damage.

Moreover, the DRAGO Thick technology doesn’t generate HAZ. All the energy in the laser beam is used during the stripping, so there is no heat accumulation due to energies below the ablation threshold of the coating.

The laser is a breakthrough solution for cleaning and stripping operations, as it enables optimal control of the process without any pollution—but until now, only operations adapted to low-energy lasers were possible. However, the DRAGO Thick laser technology dedicated to stripping and cleaning operations can remove large volumes of material with unparalleled quality and energy efficiency. ✺

JULIEN DECLOUX ([email protected]) is CEO and an optical engineer at Silltec, Saclay, France; www.silltec.com.