A team of engineers at the University of California San Diego (UCSD; San Diego, CA) and collaborators has developed a ceramic welding process that uses an ultrafast-pulsed laser to melt ceramic materials along the interface and fuse them together. The technology works in ambient conditions and uses <50 W of laser power, making it more practical than current ceramic welding methods that require heating the parts in a furnace.

Ceramics have been fundamentally challenging to weld together because they need extremely high temperatures to melt, exposing them to extreme temperature gradients that cause cracking, explains Javier E. Garay, a professor of mechanical engineering and materials science and engineering at UCSD, who led the work in collaboration with University of California Riverside (Riverside, CA) professor and chair of mechanical engineering Guillermo Aguilar.

Ceramic materials are of great interest because they are biocompatible, extremely hard, and shatter-resistant, making them ideal for biomedical implants and protective casings for electronics. However, current ceramic welding procedures are not conducive to making such devices. "Right now, there is no way to encase or seal electronic components inside ceramics because you would have to put the entire assembly in a furnace, which would end up burning the electronics," Garay says.

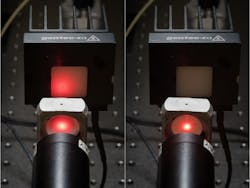

Garay, Aguilar, and their colleagues' solution was to aim a series of short laser pulses along the interface between two ceramic parts so that heat builds up only at the interface and causes localized melting. They call their method ultrafast-pulsed laser welding.

To make it work, the researchers had to optimize the laser parameters (exposure time, number of laser pulses, and duration of pulses) and the transparency of the ceramic material. With the right combination, the laser energy couples strongly to the ceramic, allowing welds to be made using low laser power (<50 W) at room temperature."The sweet spot of ultrafast pulses was 2 ps at the high repetition rate of 1 MHz, along with a moderate total number of pulses. This maximized the melt diameter, minimized material ablation, and timed cooling just right for the best weld possible," Aguilar says.

"By focusing the energy right where we want it, we avoid setting up temperature gradients throughout the ceramic, so we can encase temperature-sensitive materials without damaging them," Garay says.

As a proof of concept, the researchers welded a transparent cylindrical cap to the inside of a ceramic tube. Tests showed that the welds are strong enough to hold vacuum."The vacuum tests we used on our welds are the same tests that are used in industry to validate seals on electronic and optoelectronic devices," says first author Elias Penilla, who worked on the project as a postdoctoral researcher in Garay's UCSD research group.

The process has so far only been used to weld small ceramic parts that are <2 cm in size. Future plans will involve optimizing the method for larger scales, as well as for different types of materials and geometries.

Full details of the work appear in the journal Science.