Innovation for expanding requirements of ultrashort-pulse lasers

MILT VARDAKIS, TISSA GUNARATNE, and LARRY WALKER

Ultrashort-pulse (USP) laser micromachining, once an academic curiosity in the hands of a few research labs, has become a proliferous industrial segment over the last 20 years. The once-precipitous hesitation of industry to adopt USP lasers into daily routines has waned as more and more end users realize the positive impacts of this material processing method. This is especially true as components become smaller, and assume added physical, electrical, chemical, biological, and optical functionality to meet requirements in medical, consumer electronics, industrial instrumentation, and automotive markets.

Ultrashort-pulse laser micromachining will gain even more widespread implementation as 5G enables a world full of Internet of Things (IoT) that requires microscopic IoT gadgets whose design trends demand niche-integrated, multifunctional solutions in the shape of different sensors that include connectivity. Additionally, innovation in automation capability will offer streamlined, lower-cost micromachining workstations that can enhance operational workflow and thereby optimize end-user speed to market considerations.

Trends, growth opportunities

Mechanical and electrical engineering design trends towards monolithic componentry will be enabled by optimized mechanical and laser micromachining processes that support sensor applications in wireless communications, smart clothes, smart watches, fitness trackers, and automobiles. Application in automotive and transport will drive the IoT sensor market, as this sector is steadily transitioning toward the autonomous era, owing to the recent business collaborations and joint ventures among the automotive giants, software developers, cybersecurity providers, chip makers, and system integrators.

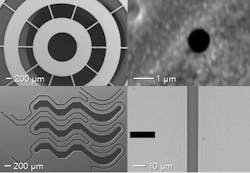

Overall, the IoT sensor market is anticipated to grow from a 2018 value of $9.6 billion to a forecasted $34.4 billion by 2024, registering a CAGR of 24.05% during the forecast period of 2019-2024. This type of growth in IoT sensor demand will result in USP laser micromachining tackling higher-level applications for 3D structuring, hole drilling, cutting, milling, and surface structuring, whose feature dimensions will include nanometers (<1 µm), smaller micro-holes (<5 µm) on tighter pitches, and higher aspect ratios (>10:1), lower tapered walls (<2%), and minimal channel widths (<50 µm) in applications such as HD multilayer rigid printed circuit boards (PCBs), flexible PCBs, integrated circuit (IC) substrates, wafer vias, calibrated flow orifices, and apertures (FIGURE 1).

The USP laser supplier landscape is comprised of a growing number of laser OEMs, automated system OEMs, non-OEM system integrators, technical consultants, and production contract service companies. Innovation leading to product and processing differentiation amongst this field of players will be key for establishing a supplier’s long-term participation in their targeted niche markets. Examples of suppliers achieving success at one key value item and developing strategic partnerships around that one item continue to grow in application areas for point-of-care devices, lab-on-chips, probe cards, flexible electronics, wafer drilling, and consumer electronics clients. With component features trending towards nanoscale dimensioning, new advances in beam pulse energy, speed/motion, spot size, wavelength, and laser system architecture innovation will naturally continue. Suppliers who provide contract services are uniquely positioned to not only machine components, but to add value when considering next-level assemblies or processes that align with the service provider’s resources and future business planning.

For a technology world moving forward at nonlinear speeds, innovative USP lasers coupled with smart automation designs enable implementation of very creative micromachining solutions that provide benefits to multifaceted business issues such as operational efficiencies, customer satisfaction, and speed to market. Companies with streamlined product development capabilities gain huge competitive advantages with increased ability to predict time-to-market and allocation of resources for rolling out the product at the right time and place. Speed-to-market product timelines contain four milestone periods: 1) generation of the product idea; 2) complete design cycle; 3) development; and 4) market launch. Skilled execution of these four stages, coupled with closely managed supply-chain resources, ensure that business plans are optimized and investors’ expectations are fulfilled.

Meeting the challenges

Effective supply chains demand alliances with partner organizations that can offer uniquely innovative products and services that quickly adapt to changing market trends and are responsive to open supply agreements. For example, capital equipment purchase decisions might be better justified by adopting innovative suppliers’ products that offer outstanding value propositions for both resource and flow efficiency work systems. Resource efficiency groups consist of highly specialized individuals where workflows from one person to another, and progress occurs only when the successive individual completes their task.

On the other hand, flow efficiency focuses on a whole team that specializes in a specific capability. This means that when one member is unavailable, the team can still work and meet scheduled deadlines. Most organizations, however, contain groups of both working models and these models can overlap, potentially putting schedules at risk such as when R&D (resource-efficient) and manufacturing (flow-efficient) departments share laser micromachining tool resources. In this instance, an innovative solution is found in the SolaFab desktop femtosecond laser micromachining workstation from Clark-MXR (Dexter, MI)—the first of its kind. This streamlined, low-cost, and easy-to-use tool is well suited for the R&D lab room’s unique workflow needs, thereby allowing manufacturing to progress uninterrupted (FIGURE 2).When capital machining equipment purchases don’t make sense, supply chains can rely on a resource-backed, experienced supplier for contract services arrangements to fulfill prototype to production-volume requirements. In these cases, the supplier is an extension of the customer’s product management team, serving as the process development, prototyping, and production resource until a production ready machine might be needed. Contract service agreements also provide opportunities where the supplier is positioned to recognize design enhancements and lower cost production opportunities through vertically integrated assembly considerations and/or more efficient manufacturing flow solutions. As an example, Clark-MXR, which manufactures femtosecond fiber lasers, depends on highly skilled artisans for precision assembly of micro-optical components. Moreover, these production skill sets are readily transferrable to other very small assemblies requiring similar micro-component bonding, alignment, metrology, and packaging strategies.

From a historical standpoint, USP laser oscillators (sometimes referred to as ultrafast or femtosecond laser oscillators) were first commercialized by Dr. William (Bill) Clark at his 1987 startup, Clark Instrumentation. Clark-MXR, as it is known today, was founded in 1992 by the merger of Clark Instrumentation with MXR, whose regenerative amplifiers used Clark Instrumentation’s seed oscillators utilizing the 2018 Nobel Prize-winning chirped-pulse amplification (CPA) technique invented by Prof. Gérard Mourou. Ultrashort-pulse laser micromachining was first commercialized by Clark-MXR based on research conducted by Prof. Mourou at the University of Michigan.Clark-MXR continues to innovate femtosecond laser sources and automated solutions now, in an employee-owned company structure. Dr. Larry Walker, President since 2017, says, “Our organization prides itself by continuing to exceed customers’ expectations on a global scale. The mission statement of the company hasn’t changed—we want our front-line scientists, our visionaries, listening to customers and formulating forward-thinking fabrication solutions, given the unique set of skills and resources under our roof.”

MILT VARDAKIS, TISSA GUNARATNE ([email protected]), and LARRY WALKER are with Clark-MXR, Dexter, MI; www.cmxr.com.