International Laser Technology Congress to inaugurate new battery lab

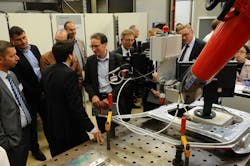

The 13th edition of the International Laser Technology Congress (AKL’20) will take place May 6–8, 2020, in Aachen, Germany, where 87 speakers will present examples of innovative solutions from industrial practice and the latest research results. Participants will be invited to experience Laser Technology Live in more than 90 presentations at the Fraunhofer Institute for Laser Technology (Fraunhofer ILT), which holds Europe’s largest laser park.

The event highlight is the inauguration of the institute’s new laboratory dedicated to research into laser processes in battery production, the Battery Lab has received some-3 million euros of funding from the European Regional Development Fund (ERDF). Covering almost 140 m2, it is equipped with different systems for laser-based manufacturing of lithium-ion and solid-state rechargeable batteries. These include roll-to-roll battery electrode coating systems used to dry and structure electrodes, a that process increases the surface area of the electrode. A coating system will go into operation at the Battery Lab toward the end of 2020. Cutting and drilling of battery components is another area in which laser technology could usefully replace conventional production processes.

Battery cells are connected together to form modules, which are in turn connected together to create battery packs. Electrical contacts are provided by welded copper and aluminum conductors. The laser joins these heat-sensitive materials because it is able to produce reliable weld seams with a low energy input. The resulting direct metal bonds also have a lower electrical resistance than screw connections. An automated battery assembly line, including a welding machine and robot, will be shown.

Since 2018, the European Regional Development Fund (ERDF) has been providing funding for the NextGenBat project, which aims to strengthen the infrastructure in Aachen and Jülich, Germany, for research on future battery generations. The existing research infrastructure in the North-Rhine Westphalia region is being expanded to create optimum conditions for companies in the region to participate in next-generation battery research and development. Alongside Fraunhofer ILT, other partners in this project include RWTH Aachen University and Forschungszentrum Jülich.

The AKL’20 conference program and registration page can be found at www.lasercongress.org; there is an early-bird discount for everyone who registers by March 4, 2020.

Got laser processing-related news to share with us? Contact David Belforte, Editor in Chief, Industrial Laser Solutions

Get even more news like this delivered right to your inbox