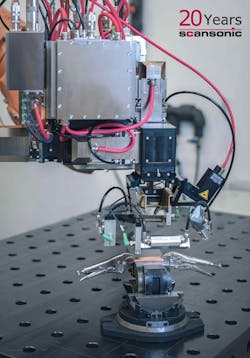

Founded 20 years ago, Scansonic (Berlin, Germany) developed a revolutionary new processing optic for high-precision brazing on car bodies (for Volkswagen) with a laser. The Scansonic ALO (Adaptive Laser Optics) system with tactile seam tracking set industry standards in automotive body construction. Since that time, the company has delivered 3300 ALO-series optics to customers who value perfect seam quality that eliminates the need for costly postprocessing and gives designers more creative freedom.

Responding to the huge demand for innovative laser processing optics, Scansonic grew rapidly, serving almost all leading international car manufacturers and supplementing this with processing optics for laser welding, hardening, and cutting as well.

Scansonic now focuses on applications for e-mobility and other industries. Examples include systems for guaranteed high-precision remote welding of copper hairpins and another for crash-resistant seams on battery pack enclosures for electric vehicles.

The company’s laser lab, which opened in 2002, is a comprehensive laser application center where process expertise originates and new optics are thoroughly tested. Working together with customers, this lab creates and benchmarks state-of-the-art applications and production concepts.

Scansonic, part of the Berlin.Industrial.Group. (B.I.G.) and currently with 120 employees, is represented in more than 50 countries by Abicor Binzel (Buseck, Germany), its international sales and service partner.

For more information, please visit scansonic.de.