Laser hotwire processing is flexible for various materials and applications

KYLE G. SMITH

Lincoln Electric (Cleveland, OH) has been in the arc welding industry for over 100 years; as recently as 10 years ago, the company became heavily involved in laser processing. With advancements made in digital welding power supplies, advancements were also being made in laser hotwire processing (LHWP). The flexibility of this process lends itself to a vast amount of materials and applications throughout many different industries. Whether it be brazing, cladding, additive manufacturing, or welding, a hotwire laser can be implemented to improve production rates and quality.

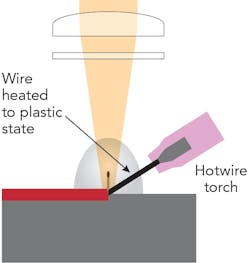

Laser hotwire processing in its most simple form combines a preheated wire contacting a workpiece in a puddle created by a laser beam of low power density, which has been done for decades (FIGURE 1). Whether preheat of the wire comes from electrons or photons, the goal is the same. The most cost-efficient way to add energy into the process is through resistance heating, which requires that current be sent through the wire over some distance. Some choose to have the heating done between anode and cathode points above the substrate, while others, including Lincoln Electric, choose to use the workpiece as one of those points. By doing so, the energy gradient is close to the deposition zone. Inherently, if too much energy is added, the wire will no longer sustain its integrity, resulting in an electrical arc. Arcing is a difficult event to recover from when using a traditional, constant voltage power source. Historically, the process needed to be run at a level much below the arcing threshold in order to maintain a stable heating.

Lincoln Electric started its venture into hotwire processing around 2010. The original hotwire equipment was based on a constant voltage (CV) digital power supply. This machine was equipped with a patented arc suppression waveform—however, the suppression time had a latency to it. Even with this machine, a noticeable difference was achieved in reference to travel speed and bead consistency. A number of these machines were implemented into automotive brazing lines. This process is typically done at a preheat level much below the arcing threshold at a lower deposition rate.

Other applications desire a much higher deposition rate. In order to operate at this level, the Lincoln Electric Power Wave LHW (Laser Hot Wire) power supply was designed to actively monitor the condition of the hot wire. The LHW power supply has the capability to suppress any sustained arcing at a very high rate, thus maximizing the temperature of the wire and consistency of the process.

Laser hotwire cladding

An excellent example of a high-deposition-rate laser process is laser hotwire cladding (LHC), which offers many benefits over traditional clad/hardfacing welding processes. LHC is ideal for corrosion and wear resistance when the part to be processed is very detailed or when there are exact chemistry specifications to be met. It’s also ideal in situations where a metallurgical bond capable of handling strains is needed that will not result in degradation of the coating. High deposition rates with high travel speed and minimal heat input are often critical in cladding operations. The more common arc processes, such as gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW), often require multiple clad layers to reach the proper chemistry and these tend to deposit thicker layers with more heat input. To address these issues of arc processing, laser cladding with powder has been implemented across industries.

Laser powder cladding offers many advantages over traditional arc based cladding methods, but there are still some associated disadvantages. Metal powder is inherently more expensive than metal wire, and the processes necessary for producing a high-quality, consistent powder are more costly than producing a heat of metal in most cases. The powder is also a bit challenging to handle from an environmental and safety standpoint, as is feeding the powder into the process.

With laser powder cladding, all of the energy to melt the powder and the substrate is coming from the laser. Some of this powder goes unmelted, and is contaminated and unusable. In LHC, a substantial amount of energy comes from resistance heating of the wire and the utilization rate is very near 100%. This results in melting more material deposited per kilowatt of laser energy. LHC is not arc-dependent.

Factors such as surface contamination, geometry, and desired travel speed are often issues with arc processes. The factors that can severely inhibit an electrical arc do not have the same impact on hotwire heating. Higher speeds result in thinner layers, with less heat input, less preparation, and less metallurgical change to the substrate. As a result, LHC cladding has a lower dilution rate compared to other arc welding processes. Arc processes of similar deposition rates have dilution rates as high as 30%, whereas LHC is often in the range of 5% to 10%.Hotwire laser welding

The lack of arc associated with hotwire laser welding (HWLW) also has benefits in thick-section, narrow-groove welding (FIGURE 2). Conventionally, pipes or plates are beveled at a large included angle and a multipass process prevents the arc from wandering back and forth between the adjacent walls. Without an arc, groove geometry can be drastically adjusted, resulting in much less volume to replace with weld metal. Often only one weld pass is needed per layer, even in thick materials up to 50 mm. Included angles of as low as 4° (2° per side) have been welded successfully using laser hotwire in carbon steel, stainless steel, and Inconel (FIGURE 3).In critical pipe welds like those in nuclear construction, HWLW has been considered an excellent alternative to gas tungsten arc welding (GTAW). Hotwire laser welding can deposit weld metal at much higher rates than GTAW, almost 5X as much or more. Also, HWLW has a lower total heat input than GTAW. This results in lower part distortion, a smaller heat-affected zone, and less residual stress. As of March 2015, the HWLW process is covered in the American Society of Mechanical Engineers Section IX Code Case 2827 under “Low Power Density Laser Beam Welding.”

Laser additive manufacturing

Another area where laser hotwire processing shows promise is in the additive world. Additive manufacturing with metal historically has been centered using powder. Powder-bed systems as well as direct-metal deposition heads have been used successfully. Inherently, these systems have the same problems associated with laser powder cladding. Using laser hotwire for additive manufacturing has proven to be a viable solution with similar benefits.

Laser hotwire is a very flexible, forgiving process that can be implemented in many different situations. Adding heat through the filler metal has proven to be an extremely efficient means of increasing deposition and travel speed while reducing overall heat input.

ACKNOWLEDGEMENT

Power Wave is a registered trademark of Lincoln Electric Company.

KYLE G. SMITH ([email protected]) is Group Leader – Laser Applications for Lincoln Electric Company, Cleveland, OH; www.lincolnelectric.com.