Laser welding process accommodates thick materials with wide gaps

Strahlkraft Lasertechnik (SKLT; Berlin, Germany) has introduced its laser multi-wire technology (LMWT) to join thick steel or aluminum plates with gap widths of up to 3 mm at very high process speeds. The company's process closes a technology gap for laser use with plate thicknesses up to 10 mm and offers a high-performance alternative to the commonly used electric arc process.

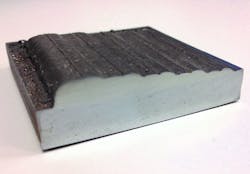

LMWT is based on a laser processing head from Scansonic (also in Berlin), which has been proven in industrial use and refined by SKLT engineers for this application. At the process point, several filler wires converge and are simultaneously melted by an oscillating laser beam. This allows seams up to 10 mm wide to be created in a single operation, depending on the number of filler wires used and the process parameters.

A smart control concept ensures wire drive synchronization and optimum energy distribution at the seam. An auto-focus keeps the spot size constant, even when component position shifts. The new process therefore functions smoothly, even under erratic joining conditions.

Among the advantages for the laser joining process are high process speeds and low thermal distortion, but so far this has required relatively gap-free positioning of the two pieces to be joined. Low gap widths (up to about 1 mm) could be compensated for with a single filler wire—however, larger gap widths or thicker plates ruled out the use of a laser. The alternative, the electric arc process, is much slower and the thermal distortion greater—LMWT has clear advantages over conventional solutions.LMWT is especially interesting in its usefulness in creating fillet welds at T-joints or lap joints with steel or aluminum materials that require large adhesion widths or seam volumes. “We see a wide range of LMWT applications for users who previously could not enjoy the advantages of the laser,” says Carsten Rösler, SKLT’s managing director. “Those users certainly include companies that manufacture ships, construction machines, and railway vehicles, companies from steel building and offshore technology, and manufacturers of machine frames and containers.” The clear quality advantages of joining aluminum make the process an attractive option for battery compartments in electrical vehicles as well.

An additional important feature of the new LMWT process is its efficiency in applying individual homogenous layers during surface finishing. All materials available in wire form can be used in such processes. This process can also be used efficiently for surface coating.

For more information, please visit sklt.de and scansonic.de.

Source: SKLT press release