Novel technologies expand laser cutting automation

BRETT THOMPSON

Laser cutting is serious business. That’s an obvious statement that will surprise no one who reads this publication, but the manufacturing landscape in North America—and around the world, for that matter—is likely to change in the post-COVID-19 world. People are feeling less and less comfortable with the globalization of the supply chain; the need for quick access to resources and the ability to promptly respond to consumer demand are key to ensuring a healthy and secure society.

TRUMPF North America realized this emerging trend years ago when it began manufacturing laser machines in its North American headquarters in Farmington, CT. Starting with a relatively modest base of U.S.-produced equipment, the company has since expanded its NAFTA-manufactured model line to include TruLaser 1000, TruLaser 2000, TruLaser 3000, and TruLaser 5000 series fiber machines—in other words, all of its primary model lines—at the Farmington manufacturing facility.

Key to success in a real-world environment is the company’s processing technologies and machine interconnectivity, which reflects a trend towards ever-greater automation either in the traditional physical sense of moving materials from point A to point B, and further highlights the automation of shop floor management and machine-based processing technologies.

It’s almost paradoxical in a day where record unemployment numbers make up every second headline in the news, but there is still a labor shortage in the manufacturing sector—and it’s one that’s getting worse. To compound this reduction in the labor pool, the skills gap is also getting worse; apprenticeship programs like those seen in Germany are a rarity in North America, and the path to a career in manufacturing is one that attracts fewer young people. This is not a surprise to any of us already in the industry. One major focus of machine tool manufacturers is to build an even better mousetrap to take a lot of the skilled requirements out of the hands of the operator and make them the responsibility of the machine.

This is no different at TRUMPF, where progressing from TruLaser1000 series fiber machines to TruLaser 5000 series fiber machines shows higher machine dynamics and an increase in the amount of processing technologies and their level of intervention during the cutting process. These various tools are used to offset operator inexperience, increase overall machine capability and performance, and to support the laser machine as a genuine tool of automation rather than “semiautonomous” manufacturing, where manual intervention is still necessary.

Let’s consider an example of just two common factors that interrupt production and require human intervention to solve: material inconsistencies and machine-based issues. These are two of the most common interrupters of production, which reduce the capability to automate and are a good focus for technological intervention.

Material variations

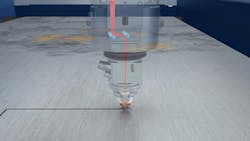

TRUMPF’s Active Speed Control is a new technology available to proactively change the condition of the laser based on real-time feedback from the cutting process (FIGURE 1). With Active Speed Control, the laser can pre-empt material issues that can cause a reduction in part quality, or an outright failure of the cut. It does so by looking at the condition of the kerf in real time to indicate if certain patterns or other indications of pending issues for the machine to anticipate and to respond.

Active Speed Control analyzes these conditions numerous times per second, allowing the machine to respond proactively rather that reactively, saving the cut. Reactive solutions to lost cut already exist and do help to an extent. The problem with a reactive solution is that it can only stop the machine once the problem has already occurred, causing either a lost part and/or stopped production. With Active Speed Control, the laser doesn’t allow the cut to degrade to the point where this can happen. It’s also doing more than just looking at the condition of the surface of the material. Certainly, there can be a layer of rust, paint, or others, sitting on top and waiting to affect the cut, but for Active Speed Control to really succeed it needs to go deeper than that (literally).

Actual material variation and inconsistencies are likewise being monitored and accommodated for by Active Speed Control (FIGURE 2). For example, a varying percentage of silicon through the thickness of the cut can cause a cut loss, likewise any impurities present that shouldn’t be. Whereas these would usually cause either a loss of the cut or at least a reduction in uniformity along the edge of the part, Active Speed Control will adjust in real time to ensure reliability and quality remain intact.Even material thickness variations are handled by Active Speed Control. If a customer orders sheets of metal from various suppliers, it’s not uncommon for the thicknesses to vary, so having Active Speed Control ensures the operator doesn’t have to intervene to make the cut clean and the process reliable. It also glimpses into an equally important capability of the system: the ability to increase feed rates. Active Speed Control has a minimum and maximum percentage change in speed that’s permissible to make sure you’re not cutting the wrong material thickness an inattentive operator may have loaded onto the bed of the laser. When cutting the thickness of material, the laser was programmed to cut, Active Speed Control will, on average, increase the productivity level of the machine by around 7%. What it’s doing is overriding the built-in “safety threshold” in the laser parameters to accommodate for poor material quality, increasing the speed to a level than is sustainable, yet over what was programmed. This means time estimates for programs using Active Speed Control are generally lower than was will be achieved in production. It’s additional profit on top of the time quoted to cut the part.

Machine-based issues

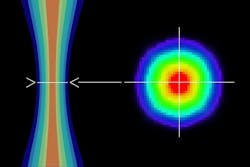

Unfortunately, a lot of issues that are machine-based are simply due to operator error or lack of proper maintenance. That’s not to say that every time a dirty protective cover glass causes sheets of material to be thrown in the bin are the operator’s fault, but to achieve true automation, there’s a need to expand the scope of machine-based processing technologies to oversee various functions. As with Active Speed Control mentioned above, we also must have automated systems to monitor and diagnose those common “consumables” that need to be in working order for successful production. Ideally, the condition of the protective glass, the center of the beam to the nozzle and the consistency of the focus position will be managed by the machine, not by an experienced operator. One benefit of working with a broad spectrum of laser applications—cutting, welding, and cladding, among others—is that you also find a technology beneficial to one process to have similar benefits for other processes.

TRUMPF has been able to monitor the protective glass condition in its welding optics by way of measuring scattered light, which translates to level of cleanliness. This system has found its way to the flat-bed laser cutting machines as a way for the machine to be monitoring—in real time—if the protective glass is dirty, but how dirty. If it’s only 20%, then it just keeps cutting. If it’s 70% contaminated, however, it will warn the operator that he, or she, had better get the protective glass corrected before production is interrupted. With the optional TruTops Monitor software, this message is relayed remotely, but in either case if the protective glass contamination level reaches 90% the machine steps in and stops production to ensure no material is being wasted. How a machine can be automated without monitoring this simple, yet critical consumable item is a mystery.An important function for the consistent use of Active Speed Control is a properly centered beam, so one of the monitored aspects of the system is the actual x-y position of the laser beam relative to the nozzle. When combined with Smart Nozzle Automation (FIGURE 4), which performs visual inspections of the nozzle post-collision or at a set time, and the possibility of achieving true automation is realized.

BRETT THOMPSON([email protected]) is a sales engineer at TRUMPF North America, Farmington, CT; us.trumpf.com.