According to an authoritative laser market report from Optech Consulting, the 2020 world market for fiber lasers used in materials processing reached 51% of an estimated $4.3 billion total. In 2017, fiber lasers held 43% of that market and the growth rate was significant because the average selling price of high power ‘decreased substantially’ while the volume of units sold ‘increased more than tenfold.’ Industrial Laser Solutions estimated a 4% increase in total fiber laser revenues for material processing in 2020 and anticipates a healthy 6+% this year. We reported that fiber lasers for material processing reached 53% of the total in 2020. Setting aside minor differences, these two leading views agree that fiber laser sales dominate the industrial laser material processing market—mostly at the expense of CO2 lasers, which no longer show annual growth rate increases.

We should not disregard a smaller, but significant, annual growth rate in solid-state laser sales—more than 2% in 2020 and 4% this year. Impetus for this growth can be attributed to a growing base of ultrashort-pulse (USP) laser suppliers opening a very diverse market for a variety of these products, many performing in non-disclosure agreement (NDI) applications. As an editor I am somewhat plagued by the latter, as many of the better and most-innovative applications go unnoticed due to these agreements that prevent their exposure in this and other publications. I understand why, but on a number of occasions I have had to ‘alibi’ for low or undefined USP laser revenue numbers that do not include these set-asides. Fortuitously when they can, there are some suppliers willing and able to share new opportunities for these lasers with readers. MKS Instruments is one—we thank them for this.

At the other end of the laser materials processing power curve, USP lasers, with their ultra-high intensities and accompanying nonlinear material interactions, continue to improve, enabling the processing of transparent materials such as glass used in industrial manufacturing through self-focusing and multiphoton (and other nonlinear) absorption, all in an otherwise highly transmissive and passive material. Terence Hollister and Jim Bovatsek (MKS Instruments) review results for through-transmission laser microwelding of glass-to-glass and glass-to-aluminum, and it appears high-power, high-PRF picosecond technology is well suited for the task (see article).

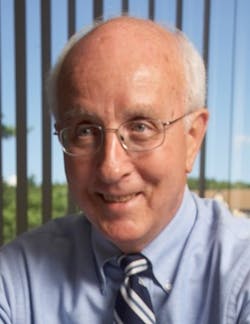

David Belforte | Contributing Editor

David Belforte (1932-2023) was an internationally recognized authority on industrial laser materials processing and had been actively involved in this technology for more than 50 years. His consulting business, Belforte Associates, served clients interested in advanced manufacturing applications. David held degrees in Chemistry and Production Technology from Northeastern University (Boston, MA). As a researcher, he conducted basic studies in material synthesis for high-temperature applications and held increasingly important positions with companies involved with high-technology materials processing. He co-founded a company that introduced several firsts in advanced welding technology and equipment. David's career in lasers started with the commercialization of the first industrial solid-state laser and a compact CO2 laser for sheet-metal cutting. For several years, he led the development of very high power CO2 lasers for welding and surface treating applications. In addition to consulting, David was the Founder and Editor-in-Chief of Industrial Laser Solutions magazine (1986-2022) and contributed to other laser publications, including Laser Focus World. He retired from Laser Focus World in late June 2022.