Laser cleaning system is designed for electric vehicle batteries

According to a random group of market reports, the 2020 electric vehicle (EV) market was 3,125,000 plug-in electric cars, expected to grow at a CAGR of 13–28% (take your pick). The market size value last year was $17.6 billion, growing to $133.46 billion in 2025. All juicy numbers, and the reason Industrial Laser Solutions predicts this market will be a market driver for industrial laser processing for the next five years.

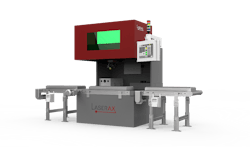

Laser-related companies are lining up for a slice of the pie. The latest is from Laserax (Quebec City, QC, Canada)—a turnkey laser solution to clean battery modules on conveyor lines. The Battery Cleaning Machine is powered by up to 500 W of laser power to minimize cycle time when preparing surfaces for welding, and offers unmatched laser cleaning quality.

The laser process and optical configuration were developed to address safety concerns specific to the EV industry, where high heat levels could lead to accidents or cause serious damage. While the laser process minimizes heat dispersion, the optical components are monitored and automatically shut down if they do not behave as they should.

To meet evolving needs of battery manufacturers, the machine includes a flexible door system that allows loading modules different ways into the machine. Modules can be loaded manually with a robot or via conveyor. Other options include a gantry system that moves the laser head to clean large modules and reach all battery cells and busbars, cameras that measure all individual cell locations and adjust laser cleaning accordingly, and a control panel that provides direct access to laser parameters.