Advances in green laser processing

The past three years have seen an explosion in the all-electric vehicle market. This electrification requires very large battery packs with lots of welding applications. Beyond the electrification of motorized vehicles, the need for electronic devices continues to grow at astonishing rates, from home power storage units for house solar panels to industrial power storage units, handheld power storage devices, battery backup units, computers, phones, and tablets. Most of these devices use copper or aluminum, which can be difficult to weld with infrared (IR) lasers, especially thin foils. Until the past couple of years, visible-wavelength lasers were very expensive and not the most robust for high-utilization industrial manufacturing. Now, visible-wavelength lasers deliver high beam quality, industrial stability, and attractive pricing.

TRUMPF (Plymouth, MI) is a full source supplier of industrial OEM lasers, from CO2, fiber, disk, diode, rod, continuous-wave, pulsed, and ultrafast, giving the company great flexibility and the ability to look at applications in order to determine the best laser to process the material. Just looking at the electric vehicle, with its battery, motors, and power distribution network, the company uses five different types of lasers, one of which is the green wavelength laser.

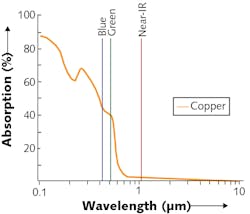

Let’s take a look at why the craze about visible-wavelength lasers exists. It all starts with absorption in copper (see Fig. 1); near-infrared (near-IR) lasers only absorb between 1% and 5% of the laser energy depending on the surface condition (polished, oxidized, clean, etc.), while lasers in the visible spectrum absorb around 40–45% of the energy at room temperature independent of surface conditions.

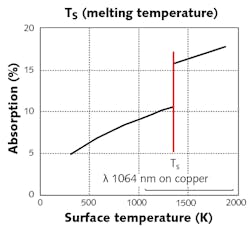

Look past the initial absorption and see, with near-IR lasers, that as we transition to the melting point, we approach about 10% absorption and then a dramatic jump to around 17% absorption (see Fig. 2). This massive spike often creates a violent reaction, causing some of molten material to be expelled in the form of spatter. In many cases, this can cause the keyhole to collapse, making the process start all over again.Green-wavelength laser advantages

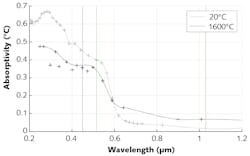

Since initial absorption is high in the green wavelength, changes in absorption of a few percentages aren’t as impactful and the process can be more finely controlled. Figure 3 looks at another breakdown of the welding process, showing absorption after transition to a molten state and clearly showing that visible wavelengths have the opposite effect, with absorption dropping a bit. This is believed to help with a stable keyhole and zero to almost-zero spatter in processing copper.So, where do green wavelength lasers excel? The short answer is conduction welds using copper, thin foil welding of copper, and basically any copper welding application that requires no spatter or need to control heat input and depth, repeatably less than 2 mm deep. Traditional welding typically is about strength and cosmetic appearance—but when it comes to electrification processes, electrical conductivity/low resistance is as important and, in many cases, more important than the strength.

Welding thin foil stacks of copper is a perfect application for green lasers. When talking thin foil stacks, we are referring to 5- to 25-µm-thick foils and typical stacks of 10–100 sheets, but any stack of three sheets or greater is ideal. As with all laser welding, gaps between layers are a problem, so clamping methods to remove gaps are critical for a successful laser weld. With an IR laser, a keyhole needs to be established for consistent absorption since the absorption varies greatly throughout temperature variations and the process is so unstable. The keyhole is very volatile and with spatter being ejected, there may be very little molten material to bridge even small gaps, causing upper layers to be cut through and therefore not making good electrical contact.

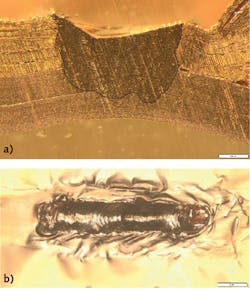

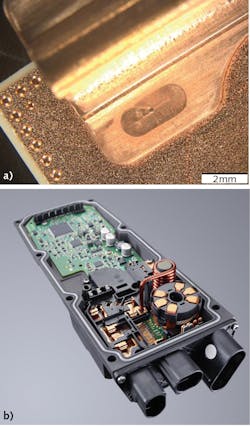

With the green wavelength, there is a controlled absorption in the process and a heat conduction weld can be used, or a stable keyhole, for thicker stack-ups, resulting in no spatter and all the molten material is able to help fill any gaps, giving an ideal weld. Figure 4 shows a cross-section of 100 sheets of 6-µm-thick copper foils welded to two 0.5 mm copper bus bars. This is done with a 2 kW green laser using a galvo scanner to create motion patterns to optimize the weld. The weld is 10 mm long and took 477 ms to weld; the weld nugget is outlined in black to make it easier to see.Other examples include circuit boards, control circuits, and power distribution/charging assemblies; again, process control and heat input are important, but eliminating spatter in these applications is critical. A small spatter ball can cause a catastrophic short in the product, which can damage the part or even create a dangerous situation for people nearby.

Application growth

Exciting emerging markets in 3D printing are laser metal deposition (LMD) and laser metal fusion (LMF) of copper (see Fig. 6). 3D printing is not a fast process, limiting much of the focus on prototype parts, configurations that cannot be built any other way, high-end parts with extraordinary strength and amazingly light weight, and manufacturing expensive materials. Processing copper with IR lasers in 3D printing is not ideal because of process fluctuations, poor repeatability, and slow processing speeds. With green-wavelength lasers, a very stable and repeatable process with low heat input and fast processing speed can be achieved.In 2021, TRUMPF introduced its BrightLine Weld dual-core technology for green laser wavelengths. This has shown to improve some of the difficult processes like deep-penetration, spatter-free welding of copper greater than 2 mm thick.

Conclusion

As the electrification of vehicles continues to grow with the spread of battery technology, the processing of copper and aluminum will be at the forefront in the coming years. Using green-wavelength lasers will be an important tool in this processing revolution. The high absorption into copper, greater than 40%, and its insensitivity to varying surface conditions make the green laser the perfect choice for process stability and flexibility in manufacturing. This is critical in welding battery foils, foils to bus bars, controlling the depth and heat of copper mounted to ceramic insulators, and more. Low heat input, consistent penetration, and lack of spatter are key when welding on a completed electrical circuit because having to scrap that expensive part because of thermal damage or electrical short caused by a piece of spatter from welding is not ideal. As new lasers are developed and processes are enhanced, green-wavelength lasers will play an important part in the growing electrification market.

Tracey Ryba | Product Manager for Lasers, TRUMPF Laser Technology Center

Tracey Ryba is Product Manager for Lasers at the TRUMPF Laser Technology Center (Plymouth, MI).

Travis Stempky | High Power Laser Application Supervisor, TRUMPF Laser Technology Center

Travis Stempky is High Power Laser Application Supervisor at TRUMPF Laser Technology Center (Plymouth, MI).