Laser beam shaping for battery welding

The battery market is approaching the tipping point, when battery prices fall below the industry consensus $100/kWh, electric vehicles (EVs) will match internal combustion engine vehicles (ICEs) on purchase price. The passenger vehicle market is the largest volume application for batteries and has been pushing advances in battery technology and manufacturing efficiency. As EV and hybrid vehicle sales continue to ramp, improvements in performance and price are compelling other battery markets to accelerate. For the stationary power market, battery advances offer more valuable solutions for clean energy storage and peak shaving. Delivery trucks and public transit in the commercial vehicle market, as well as two-wheeled transit for personal mobility, will draft off the improvements in energy density, charge cycle, and reliability driven by the passenger vehicle market. Price parity between EVs and ICEs is expected to occur in only a few years.

Laser integrators, system builders, and laser enthusiasts understand how exciting this rapidly growing battery market is for the laser industry. The increasing demands in battery packaging efficiency, weight reduction for pack energy density, and faster cycle times for higher production volumes are being solved by new laser processing solutions. Battery manufacturers in medical and aerospace have used legacy pulsed YAG laser welding, ultrasonic welding, or resistance spot welding to join thin copper, aluminum, stainless, and nickel components, but these legacy processes have slower cycle times or require larger weld tab geometries that are incompatible with the production demands and weight limitations of EVs.

In the electrified transportation market, fiber lasers have quickly overtaken these legacy processes due to superior processing value (production speed vs. operating cost). Fiber lasers are used to cut the anode and cathode foils, weld foil tabs, seal prismatic cans, assemble current interrupt devices, bus cells into modules, and join modules into structural packs. As battery packaging efficiency demands increase, single-mode fiber lasers are becoming more popular than multimode lasers due to the narrower weld size, lower heat input, and higher intensity.

Challenges for laser welding

Like other manufacturing process, battery welding still has several challenges confronting manufacturers. Evolving product designs and shifts in the supply chain can impact the quality and repeatability of the parts to be welded, leading to significant part-to-part variability.

Of the metals used in battery production, copper and aluminum are more challenging to weld than steel, stainless steel, and nickel. Both have high heat conductivity, low liquid viscosity, and an affinity for picking up gases in the molten weld pool. To produce fusion welds in copper and aluminum, the welding process must be very fast with low heat input to avoid overheating nearby components. To avoid weld spatter and porosity, the fusion process must be stable at high speeds despite any joint variability.

For structural connections, welds need to be as strong as possible without requiring an increased joint area for the welding process, as this additional weight reduces energy density. For electrical connections, the weld area needs to be wide enough for current carrying capacity while limiting distortion that can be caused by large melt volumes. For combination structural-electrical joints, the welding process must work within the constraints of the product design to achieve the best balance. All of these challenges, combined with extreme cycle speed and quality requirements, can lead to a very narrow operating window for laser welding engineers.

Single-mode beam shaping for the battery processing toolbox

Single-mode fiber lasers have proven to be an effective solution for these challenging welding conditions. The small spot size and high power density of the single-mode beam is able to produce deep penetration welds at very high speeds with little heat input and low distortion. The intensity available from single-mode fiber lasers can easily overpower the reflectivity of copper and aluminum during keyhole welding. From foil tab connections and small structural welds to thicker electrode connections, single-mode fiber lasers have established their reputation as a versatile and valuable battery processing tool.

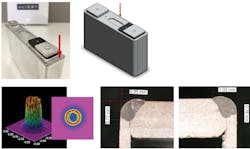

In recent years with the introduction of beam-shaping fiber lasers, battery integrators have shown the value of ring-shaped beams for welding thicker aluminum such as prismatic cell cap-to-can (see Fig. 1), multicell module bus bars, module housings, structural pack frames, and aluminum EV body welding.

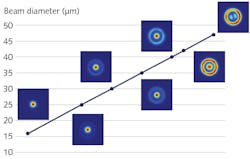

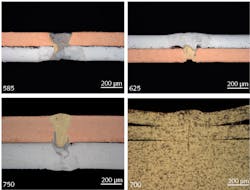

nLIGHT (Vancouver, WA) has recently transferred this tunable beam shaping functionality to single-mode fiber lasers combining the benefits of ring-shapes with the intensity of single-mode beam quality. The company’s AFX series fiber lasers offer the capability to dynamically change the laser power distribution from a single-mode fiber up to a 40 µm ring fiber (see Fig. 2). This tunability offers versatility from the laser source to accomplish a wide range of welding tasks for battery materials.For welding aluminum joints, the larger ring beam shapes are advantageous for maintaining a stable weld pool and keyhole during processing. At 3X larger diameter than the single-mode beam, the intensity of this 40 µm ring beam at 1 kW is still sufficiently high to form a vapor cavity in the aluminum for applications like bus bar and foil tab welding. This combination of power density and a wide beam shape results in a wide, smooth weld surface with little to no spatter. By shifting more of the power to the ring, the keyhole shape transforms from a narrow capillary to a wide-bottom cylinder, allowing vapor and entrapped gases to escape before solidification. Additionally, this wider beam shape produces a wider weld bead without the penetration spiking often seen when welding aluminum with Gaussian beam shapes at slow speeds.

When welding ferrous, nickel, or dissimilar alloy combinations, the intermediate beam shapes provide the flexibility to change the balance of power between the intense single-mode core and the wide ring beam tailored for each application. At high speeds, most of the power is often directed to the center core for the deepest penetration. If the speed is reduced to produce a wider weld or due to machine acceleration and path geometry, more power can be shifted to the ring. With the intermediate beam shapes (see Fig. 2), the penetrating power is provided by the single-mode core and the power in the ring vaporizes the metal around the keyhole, widening the top opening of the vapor cavity. This fraction of ring power alters the keyhole shape to be more cone-shaped than a narrow capillary. This wider keyhole opening results in a more stable process with fewer spatter ejections and weld surface fluctuations. If the speed is further reduced, more power is shifted to the ring to prevent momentary collapse of the keyhole and further widen the keyhole opening. The versatility in spatial profile provided by AFX single-mode beam shaping fiber lasers enables a broad range of processing conditions from a single laser source.

Summary

As the battery market repeatedly breaks records in performance, price, and manufacturing scale, battery producers are looking to add new tools and capabilities to their kit of welding solutions for new challenges in production speed and product evolution. While most of the manufacturing challenges facing battery producers are not new to laser processing, the scale and complexity of the tasks facing system builders is unique. Laser beam shaping has proven to be a valuable tool in the laser process engineer’s toolbox. The innovative combination of beam shaping and single-mode beam quality in a single laser source adds the processing flexibility to control keyhole stability and weld quality while maintaining the high intensity necessary for welding battery materials. With declining battery prices and increasing production volumes, the horizon for battery applications and the EV market is specifically exciting for the laser industry.

About the Author

Tim Morris

Welding Market Development Manager, nLIGHT

Tim Morris is Welding Market Development Manager at nLIGHT (Vancouver, WA).

Brian Victor

Director of Industrial Applications, nLIGHT

Brian Victor is Director of Industrial Applications at nLIGHT (Vancouver, WA).