Lasers are widely used in medical device manufacturing and the full range of available laser types makes them suitable for many different processes, including marking, welding, cutting, and micromachining. Each process serves very specific needs, with new applications surfacing constantly.

Laser marking: Product information and traceability

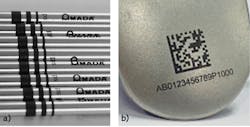

Laser marking is an excellent way to permanently mark company logos and product/part information onto a device to ensure traceability. Laser marking is considered a type of direct part marking (DPM) process, and its flexibility allows for easy creation of unique device identifier (UDI) marks, company logos, and information about or text/graphics on device usage (see Fig. 1). It is used for a wide range of medical and dental devices, including bone screws; cases that house delicate electronics, like pacemakers; auditory implants; intraocular lenses; and endoscopic tools.

There are several industrial laser sources suitable for laser marking, which are categorized based on wavelength, laser medium, or pulse duration. These include UV, green, fiber, carbon dioxide (CO2), and ultrashort-pulse (USP) lasers. The material properties and desired mark type and quality determine the best source.

One growing trend and specialized application of lasers in the industry is the marking of stainless-steel medical devices, where the mark must be:

- Dark, black, and visible from a wide variety of angles

- Corrosion-resistant

- Free of surface inclusions (no engraving)

- Biocompatible

- Able to survive multiple cleaning passes (autoclave)

For this application, USP lasers achieve the best overall results and pass rigorous testing via salt spray, autoclave, and acidic cleaning. This type of mark is often used for the banding of tubes (such as cannula and trocars) with gradations to determine insertion depth.

Laser welding: Micro-joining intricate parts

Medical devices are often handheld (or smaller) parts and are often used or implanted during surgery. The welds that hold these parts together are critical for the health of patients and as such are rigorously controlled, requiring reproducible pulses, small spot diameters, and precise penetration into the material.

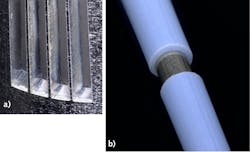

Often called laser micro-welding, this process results in penetration and weld spot sizes under 1 mm. Micro-welds are often used for pacemakers, surgical blades, endoscopic instruments, and batteries.

A variety of laser sources are suitable for micro-welding, including pulsed neodymium yttrium aluminum garnet (Nd:YAG), continuous-wave (CW) fiber, nanosecond fiber, quasi-continuous-wave (QCW) fiber, and high-brightness direct-diode (HBDD) lasers. Process requirements, manufacturing needs, and materials determine the most appropriate laser source.Laser micro-welds can be categorized into two types: spot welds and seam welds (see Fig. 2). Spot welding of medical tubes, electrical contacts for fine springs, hook assemblies, guidewires, and medical hypo wires require precision energy delivery and tooling. The achievable spot size depends on the laser type and its beam quality:

- 20–200 µm spots—fiber lasers (CW, QCW, and nanosecond)

- 200–1000 µm spots—pulsed Nd:YAG lasers and HBDD lasers

Seam welding, the method used to hermetically seal implantable devices, can be achieved with pulsed Nd:YAG or CW lasers. The deciding factor of which laser to use may be critical aspects of the geometry or part sensitivity to heat.

There has been a recent trend with ever-increasing complexity of parts to join dissimilar materials. This refers to materials as disparate as copper and aluminum, or as seemingly close as two different aluminum alloys. In general—and traditionally—mixing of different metals should be avoided because the resultant weld may create brittle intermetallics. However, new research shows that by minimizing the melt pool via shorter interaction time with the laser, some dissimilar metal connections can be made. These welds, like any other, need to be tested for fitness and purpose, but this opens the possibility of novel connections and materials that may push the boundaries of medical devices further.

Laser cutting: Implantable devices and surgical tools

Laser cutting in the medical device field is most often used to create tube-shaped products, like implantable stents, endoscopic and arthroscopic tools, flexible shafts, needles, catheters, and hypotubes, as well as flat products, like clips, frames, and meshes. These devices are critical for enabling advanced surgical procedures and for improving the health and quality of life of millions of patients.

Medical device laser cutting is typically performed with a pressurized assist gas—usually oxygen, argon, or nitrogen—that flows coaxially with the beam from either a fiber laser with microsecond- or nanosecond-duration pulses, or from an USP laser with pulse durations in the hundreds of femtoseconds.

Fiber lasers are more widely used due to their affordability, good beam quality, and ease of integration with optical fiber delivery. Fiber lasers excel at cutting thicker metals, such as stainless steel, titanium, cobalt chromium, and nickel titanium, generally from about 0.5 to 3 mm in thickness.

This makes fiber lasers ideal for cutting surgical saws, blades, and large surgical drills with flexible shafts. However, because fiber laser cutting is a thermal process, the parts typically exhibit burrs, dross, and heat-affected zones after cutting, necessitating the use of post-process cleaning techniques like tumbling, deburring, and electro-polishing, before the parts can be put to use.

USP lasers provide unique capabilities that distinguish them from fiber lasers. Extremely short pulse durations—particularly of femtosecond lasers—allow USP lasers to remove material from a surface with almost no thermal input. How? The high peak power of these pulses enables efficient nonlinear photon reactions, allowing more input energy to be directed toward material removal. The individual pulses are shorter than electron relaxation times, so they vaporize the target before thermal conduction to the surrounding material occurs. This results in excellent cut quality, nearly perfectly clean cut edges with minimal heat-affected zone, and surfaces that require almost no post-process cleaning steps.

Since post-processing is expensive, time-consuming, and can lead to reduced production yields due to part breakage, USP lasers are attractive for parts made from expensive materials like nickel titanium, with small, delicate features that are susceptible to breaking. Neurovascular stents, cannulae, needles, and very small-diameter tubes with wall thicknesses less than 0.5 mm are best processed with USP lasers (see Fig. 3).Laser micromachining: Surface structuring

For medical device applications requiring microscopic features, pristine surface finishes, and a high degree of flexibility on materials and geometries, laser micromachining is a powerful technology that is rapidly replacing traditional methods like CNC milling, EDM, and chemical etching. As with laser cutting, USP lasers provide the best processing precision, stability, and quality. Since these lasers are offered in multiple wavelengths including infrared, green, and UV, they can be optimized for metals, polymers, ceramics, glasses, and organics.

USP laser micromachining is an excellent choice for drilling round, elliptical, or square holes into small needles, guidewires, cannulae, and catheters, and even multilayer tools made up of both metal and polymer (see Fig. 4). Circular holes smaller than 25 µm can be drilled in thin materials, allowing precise control over fluid delivery or suction for the final products.Tight-tolerance surface structures and textures are readily created with USP laser micromachining, with material removal depths as precise as ±1 µm in metals and ±2.5 µm in polymers. Surface structures are critical for creating adhesion surfaces between layers of polymer medical balloons and for textured surfaces on surgical tools.

The high degree of process control provided by USP lasers allows them to selectively ablate or strip materials from underlying surfaces. This is a useful capability for multilayer medical catheters, which often require specific area removal of a polymer coating down to the interface with the underlying metal layer, without causing any damage to the metal itself.

USP laser micromachining is accomplished with a range of standard optical and optomechanical components that can provide precise beam delivery control. Galvo scan heads, fixed-optic focus heads, and multi-axis scan heads allow for flexible, yet precise, process development and optimization.

Lasers are used in medical device manufacturing, including in processes such as marking, welding, cutting, and micromachining. Selection of the right laser for every process is important to achieve the desired results and stability for repeated success. A comprehensive understanding of the process fundamentals opens new opportunities that are driving innovation in the medical device field.

Brennan DeCesar | Manager, Advanced Technology at Amada Miyachi America

Brennan DeCesar is Manager, Advanced Technology at Amada Miyachi America (Monrovia, CA).

Mark Boyle, Ph.D. | Product Manager, Amada Weld Tech Inc.

Mark Boyle is Product Manager at Amada Weld Tech Inc. Mark is responsible for technical product management of the company’s product lines, including laser, micro TIG, resistance welding, seam sealing, hot bar, and systems.